24

18x105

After Failure

16

14

8

10

Before Failure

6

0.02

0.03

0.04

0.05

0

0.02

0.04

0.06

Discharge (m3/s)

Discharge (m3/s)

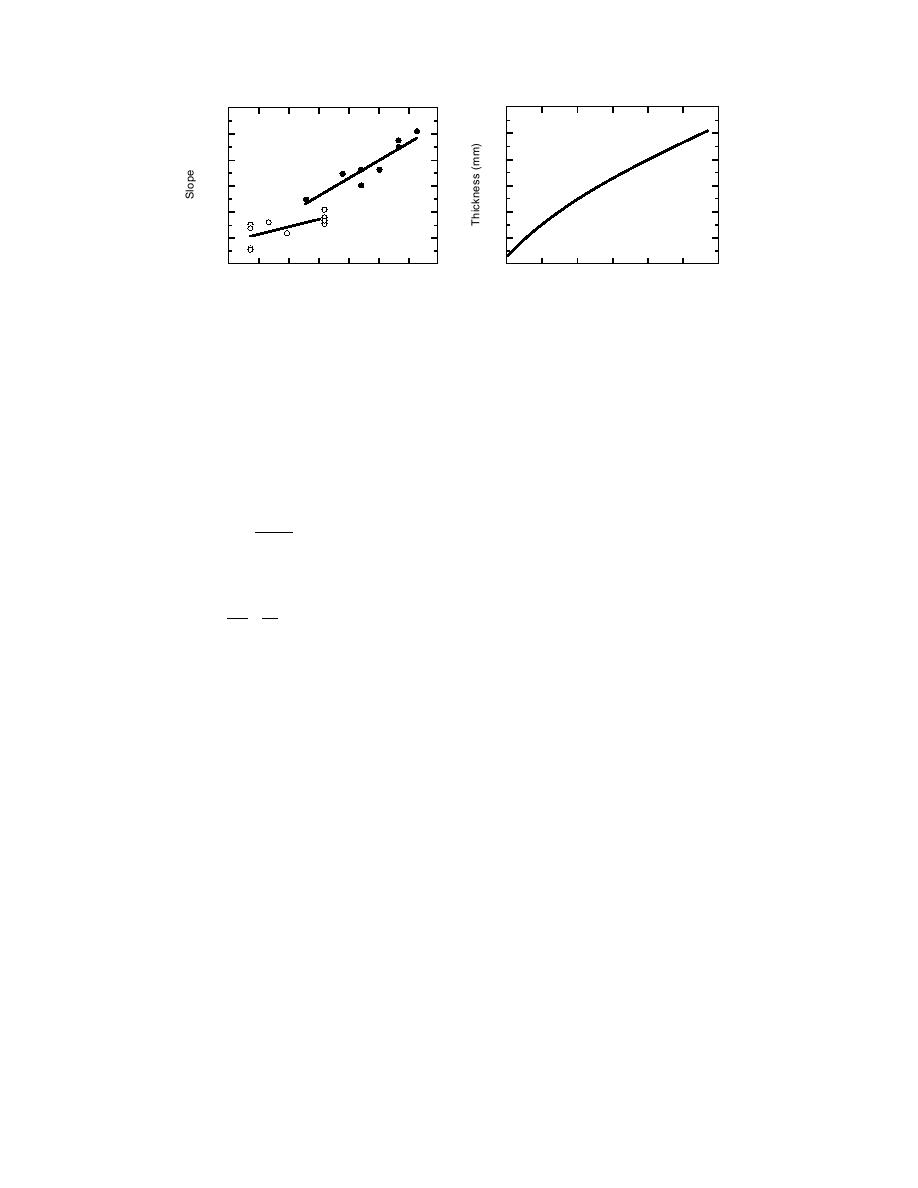

Figure 19. Slope vs. discharge, showing in-

Figure 20. Calculated equilibrium jam

crease in slope after jam failure.

thickness vs. discharge.

in which u is average flow velocity and R is the composite or total hydraulic radius.

An average value of fo was calculated and used for the conditions before and after

failure. The detailed velocity profiles from each test provided data on the ratio of

the bed-affected to ice-affected hydraulic radii. Then, using the Sabaneev equa-

tions

fi + fb

fo =

(32)

2

and

f

Ri

= i

(33)

Rb fb

it is possible to determine ratios of fi to fb and fi to fo. Average values of these ratios

for the conditions before and after failure were calculated and used to calculate the

equilibrium cover thickness expected for each experiment. Figure 20 is a plot of the

equilibrium thickness vs. discharge for this series of experiments, using average

values of fo and fi/fo.

Figure 21 follows the changes in thickness experienced with step changes in

discharge for one of the experiments. The initial thickness of a bead jam is slightly

greater than that predicted using the equilibrium theory (eq 30) and was between

one and two beads thick. Two step increases in discharge were necessary before a

shoving and thickening event occurred, with the resulting thickness again slightly

greater than that expected by theory. This first failure was a progressive jam failure

with very small ice velocities. Two more step increases in discharge were necessary

to again cause jam failure. The second failure was a complete jam failure, with the

whole cover mobilizing en masse and thickening taking place initially at the down-

stream screen. The final thickness was significantly greater than the equilibrium

value for that flow level.

The jam failures in each experiment were identified as either progressive or com-

plete jam failures. The final thickness following failure was plotted in Figure 22

against the equilibrium thickness predicted using eq 30. The progressive jam fail-

ures resulted in accumulation thicknesses that plotted on or very slightly above the

equality line in the figure. The complete jam failures, however, exceeded the equi-

librium thickness in every case, often by a significant amount.

27

Previous Page

Previous Page