0.2

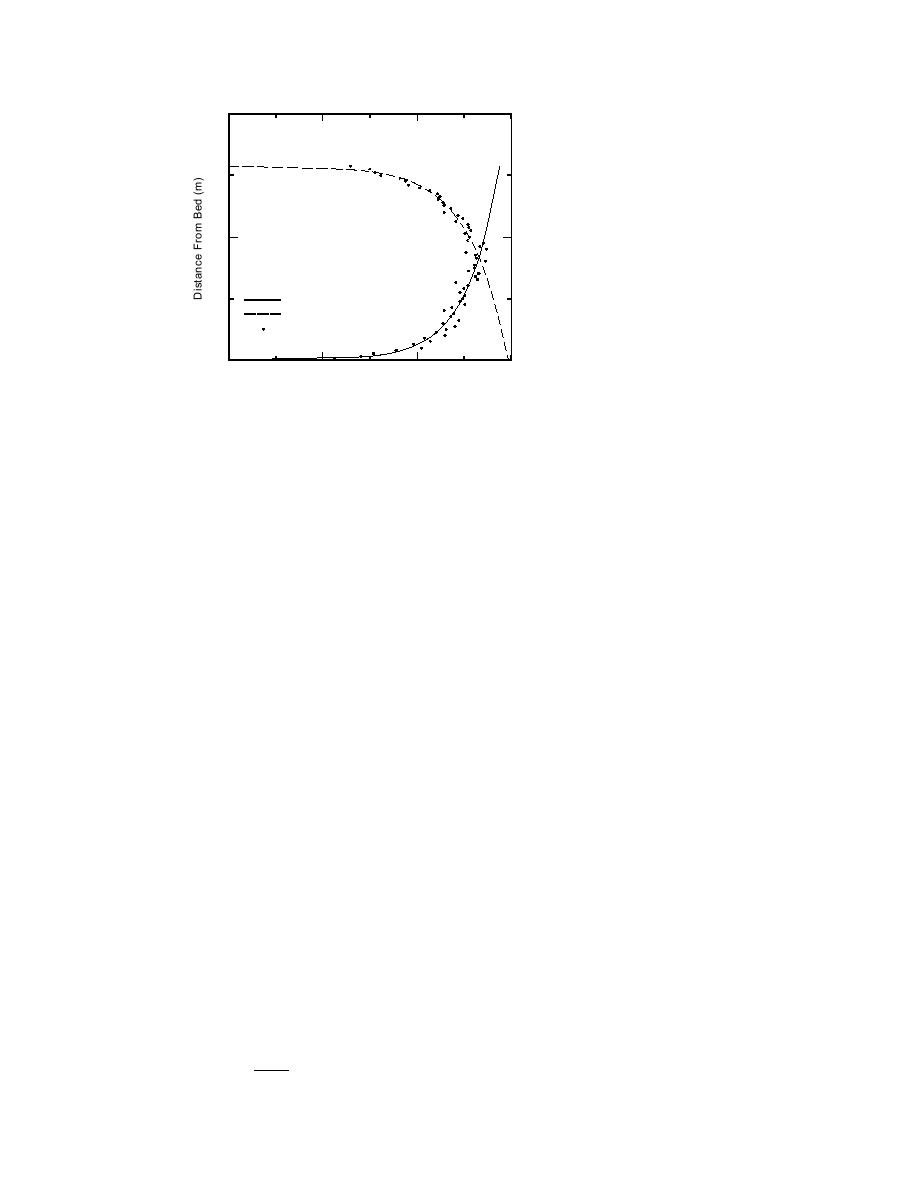

Figure 18. Measured velocity

0.1

profile with fitted log-law equa-

tions for the ice and bed-affected

areas.

Lower Layer

Upper Layer

Measured

0

0.1

0.2

0.3

Velocity (m/s)

log-law profiles calculated for the bed- and ice-affected portions of the flow area.

By assuming the line of zero shear stress to be equivalent to the intersection of the

two computed profiles, the depth of the ice-affected flow area could be determined

and the hydraulic radius Ri of that region calculated. The value of was then calcu-

lated by back substitution into eq 30, using the measured value of accumulation

thickness in the equilibrium reach. The value of was found to average 0.75 for the

three steady flow discharges considered. Though this value is at the low end of the

range of 0.81.3 reported by Beltaos (1995), it reflects the effect of the difference

between the shape of the beads and natural ice rubble. The beads are uniform in

size and approximately cylindrical in shape, thereby having an angle of repose less

than that of natural ice. The uniform shape of the beads causes their accumulations

to deform more easily under stress and results in a lower Kp and thus value than

is the case for natural ice rubble in a jam.

With a known average value of determined for the beads, further experiments

could proceed using the tiltable-bed flume without refrigeration. Fifteen experi-

ments were conducted under a variety of initial discharges and discharge increases,

as reported by Zufelt (1992). Each experiment was run in a manner similar to the

visualization series, for which a bead cover was allowed to form at a low discharge

and the flow then increased in steps until a shoving and thickening event took

place. The energy slope was assumed to be equivalent to the water surface slope,

which was calculated from measurements of water surface elevation along the flume.

Slope was plotted against discharge, and a linear relation was obtained for the

conditions before and after failure. Though a power relationship is to be expected

between slope and discharge, the linear fit was adequate for the limited range of

discharges used. The two relations also confirm an increase in jam roughness fol-

lowing failure and thickening, as evidenced by the higher slopes following failure

(Fig. 19).

The variations in slope for similar discharges before failure in Figure 19 reflect

slight variations in the configuration of the bead jam (thickness, extent, etc.)

between successive tests. The slopedischarge relation was used for further calcu-

experiment as

8gRS

fo =

(31)

u2

26

Previous Page

Previous Page