The study used a laboratory flume and a jam formed of ice pieces and plastic beads.

The jam was destabilized by means of flow increases. The qualitative observations

provided the insights necessary to numerically model unsteady jam formation. A

brief series of quantitative experiments was also undertaken to address the appli-

cability of equilibrium thickness theory for determining jam thickness, following a

shoving and thickening event.

Experimental setup

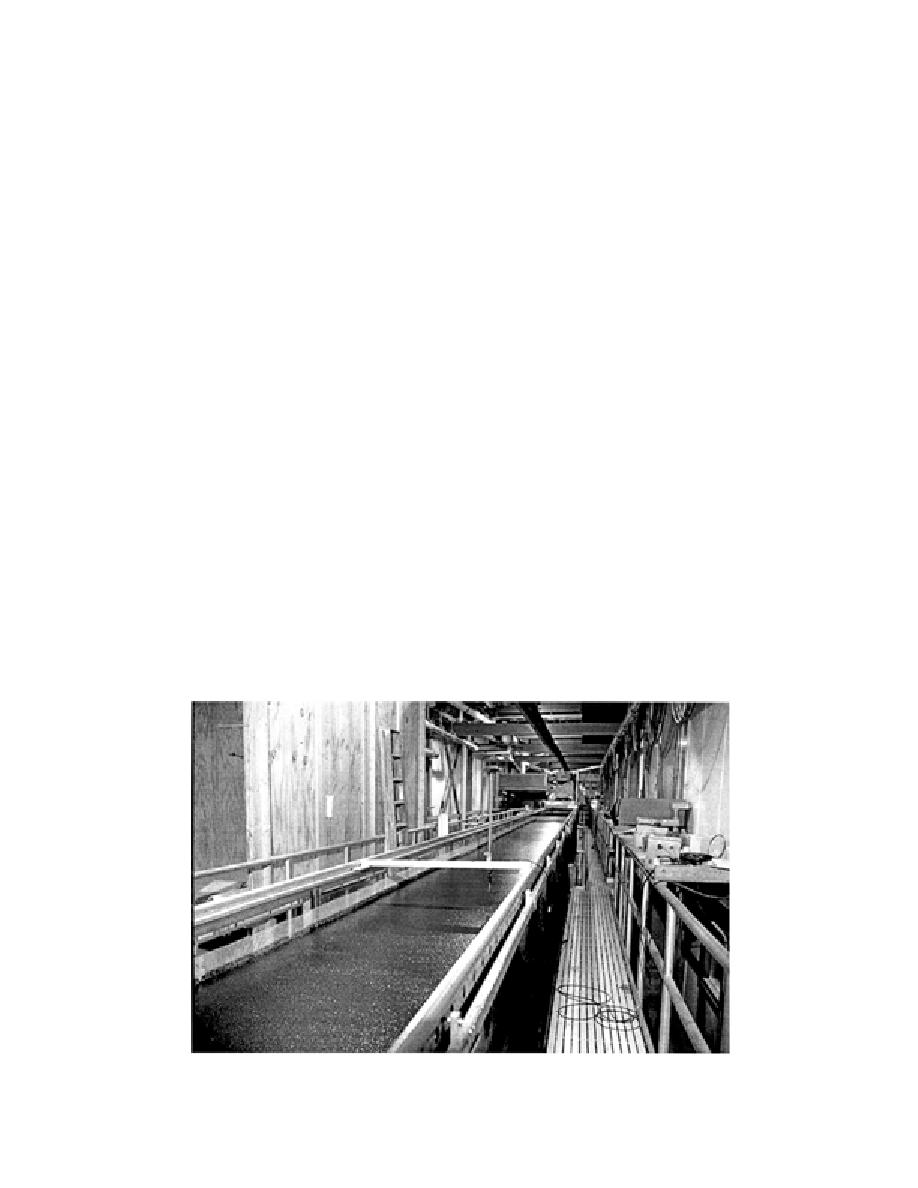

The experiments were undertaken in three different flumes using real and plas-

tic ice. Two of the flumes are refrigerated. One flume has a fixed slope bed (So =

0.0033), is 1.22 m wide with a working depth of 0.61 m, and is 22.9 m long. The

second flume is tiltable, 36.6 m long with a working section of 1.22 m wide by 0.61

m deep (Fig. 15). Both flumes are housed in refrigerated rooms in which air tem-

peratures can be regulated to 23C. A selection of pumps delivers water from large

sumps to each flume, resulting in non-recirculating flow. The sumps contain chiller

coils to further reduce water temperature. The quantitative experiments were con-

ducted using the tiltable flume and a third, unrefrigerated flume. This latter flume

has a fixed horizontal bed, is 7.3 m long, and has a working section that is 0.92 m

wide by 0.92 m deep. It has a large sump and can be operated in either the fully

recirculating or "once through" mode.

The visualization experiments entailed initially forming ice covers made of a

single layer of ice or plastic beads. Then, water discharge was increased to destabi-

lize the cover and induce shoving and thickening. For the experiments with real

ice, ice pieces were formed from a thin sheet (about 15 mm) grown in the flume at

very low flow. The randomly shaped pieces were approximately 80120 mm in

their longest dimension. Air temperature was increased to about 0C, and the flow

was increased until the ice pieces collected as a single-layer accumulation, or jam,

held in place by a screen at the downstream end of the flume. The flow rate was

Figure 15. CRREL refrigerated, tiltable flume.

21

Previous Page

Previous Page