Tensile failure and extension data from simple

Table 2. Tensile failure and extension data from simple

tension tests of various silicone joint sealants. (From

tension tests of various silicone joint sealants have

Spells 1987.)

been described in the literature by Spells (1987) and

are reproduced in Table 2. The sealants were des-

Force per unit

ignated by Spells as high modulus, medium modu-

unstrained area at

Sealant

extension ratio = 1.5

Extension ratio at

classification

(kPa)

breaking failure

10

1

10

10

High modulus

690

5

Medium modulus

276690

512

9

10

a.

10 0

Low modulus

276

12

10 8

(G1

1

Tan δ

10

Pa) 10

7

50

2

10

Fre( uency

q

6

lus, and low modulus sealants in order to demon-

10

500

Hz)

000

strate their range of deformation capabilities, and

10 5

10 3

were tested according to standard procedures

80

40

0

40

80

120

10

1

(ASTM 1991d) at near room temperature. For each

10

10

category the table lists the force per unit of the

9

10

b.

original, unstrained area at an extension ratio of

10 0

1.5, and the extension ratio at breaking failure.

10 8

(G

Very few data exist in the literature regarding

1

Tan δ

1

10

Pa) 10 7

the effect that temperature has on sealant proper-

ties, although in the rubber and polymer industry

2

10

6

10

such material property data are routinely gener-

ated for evaluating the effectiveness of the mate-

5

3

10

10

80

40

0

40

80

120

rial, and standard test methods are suggested for

10

1

10

10

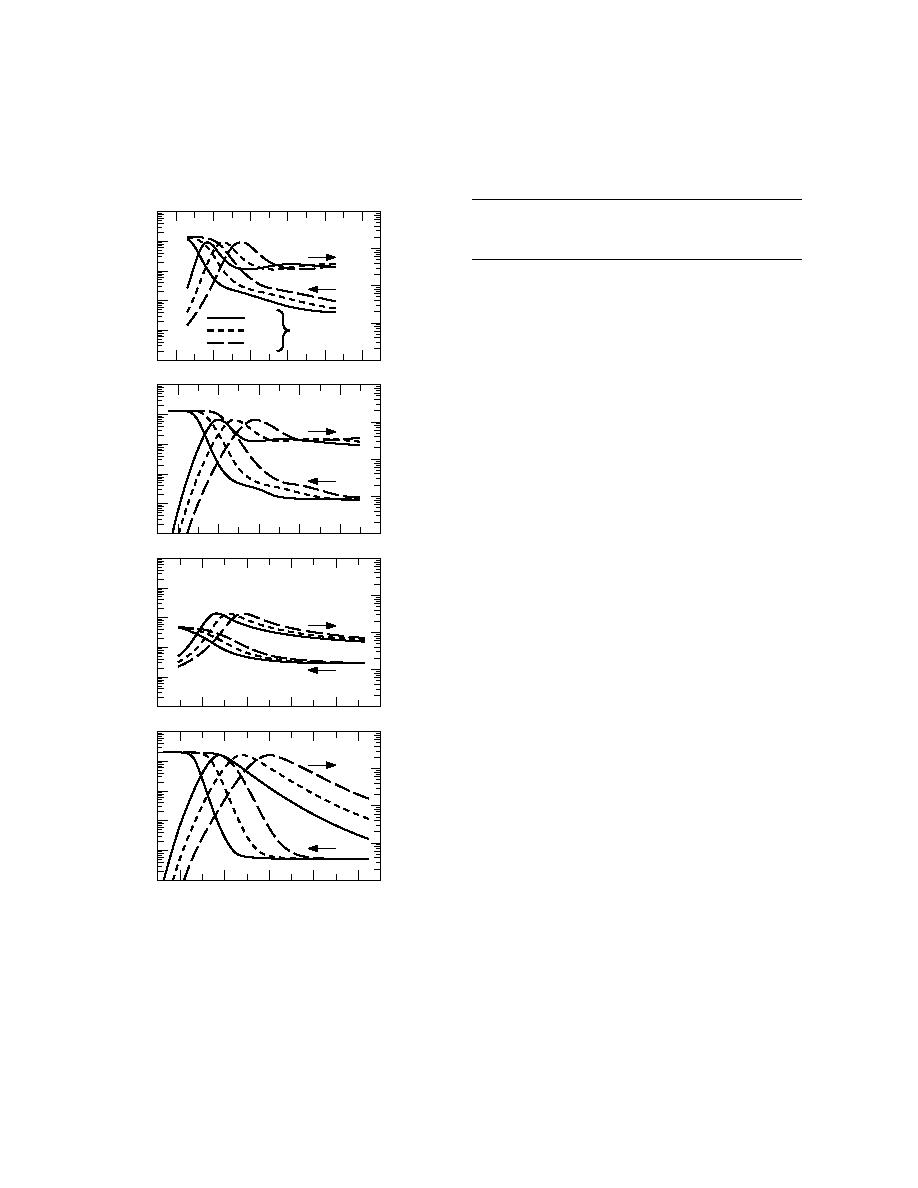

obtaining the data (e.g., ASTM 1991c). One ex-

ample of shear modulus vs. temperature data from

9

10

c.

10 0

low-strain harmonic loading tests of a sealant is

10 8

shown in Figure 6. The data are for a polysulfide

(G1

1

Tan δ

10

sealant tested at three loading frequencies using a

Pa) 10 7

beam test, from a publication of Nashif and Lewis

2

(1991). The real part of the shear modulus G(G =

10

6

10

G1 + iG2) and the loss factor tan δ (tan δ = G1/G2)

5

3

are shown. Also shown from this publication, for

10

10

80

40

0

40

80

120

purposes of comparison, are corresponding data

10

1

10

10

sets for a polysulfide elastomer, a urethane elas-

9

tomer and a natural rubber.

10

d.

10 0

More general reviews of the characteristics of

8

10

sealants have been given by Panek and Cook (1984)

(G1

1

Tan δ

10

and the American Concrete Institute (ACI 1993).

Pa) 10

7

2

10

10 6

MECHANICAL

5

3

RESPONSE OF SEALS

10

10

40

80

80

40

0

Temperature (C)

The current state of knowledge of the mechani-

Figure 6. Examples of the real part of the complex shear

cal response of joint and crack seals comes prima-

modulus G (G = G1 + iG2) and the loss factor tan δ

rily from field and laboratory experimental stud-

(tan δ = G2/G1) as functions of temperature from low-

ies of the deformation capabilities of pavement and

strain harmonic loading tests of (a) a polysulfide seal-

building seals. As indicated by the extent of the

ant, (b) a polysulfide elastomer, (c) a urethane elastomer,

experimental work that is documented in the lit-

and (d) a natural rubber, all tested at three loading fre-

erature and by the concerns of the practitioners

quencies in beam tests. (After Nashif and Lewis 1991.)

who are charged with sealing joints and cracks,

8

Previous Page

Previous Page