revealed by a selection of analysis results and ex-

the structural performance of seals is of great in-

perimental measurements, is reviewed.

terest to civil and pavement engineers. Although

it is generally recognized that the low-tempera-

ture extreme of the seasonal temperature cycle can

Basic structural geometry and

lead to failure of the seal if the material hardens

loading configurations of seals

In general, portland cement concrete pavements

significantly and the seal is extended by the move-

are constructed with regular joint patterns and

ment of the joint or crack (e.g., ACI 1993, Beech

spacing to avoid cracking of the pavement from

1985, Catsiff et al. 1970a), very little work has been

thermal response and shrinkage of the concrete,

conducted to quantify the effect of low-tempera-

whereas asphalt concrete pavements are rarely con-

ture variations on the structural response of seals.

structed with built-in joints. When cracks are sealed

In this section the basic geometry of seal structures

in asphalt concrete pavements, where crack pat-

and their loading is discussed; conventional ex-

terns can vary from regular spacings of relatively

perimental techniques for studying pavement joint

straight transverse and longitudinal cracks to ir-

and crack seals are described; and the mechanical

regular patterns of meandering cracks, it is con-

response of seal structures to joint movements, as

ventionally recommended that butt joint reser-

voirs be formed along the cracks using sawing or

routing construction techniques (e.g., Lynch 1990).

Some authors, however, without presenting analy-

ses to support their contentions, have suggested

that seal performance is not improved by this tech-

Backing Rod

nique (Panek and Cook 1984). Further, in the case

of reflection cracks in asphalt concrete overlays of

portland cement concrete pavements, where the

crack patterns typically follow the regular joint

pattern of the portland cement concrete pave-

ment, it is also conventional practice to construct

butt joint reservoirs along the cracks by sawing or

routing the cracks. For these reasons little distinc-

tion is made in this section between seals formed at

joints and at cracks and between seals in portland

cement concrete joints and in asphalt concrete

joints, although the term crack is used in refer-

ence to asphalt concrete pavements.

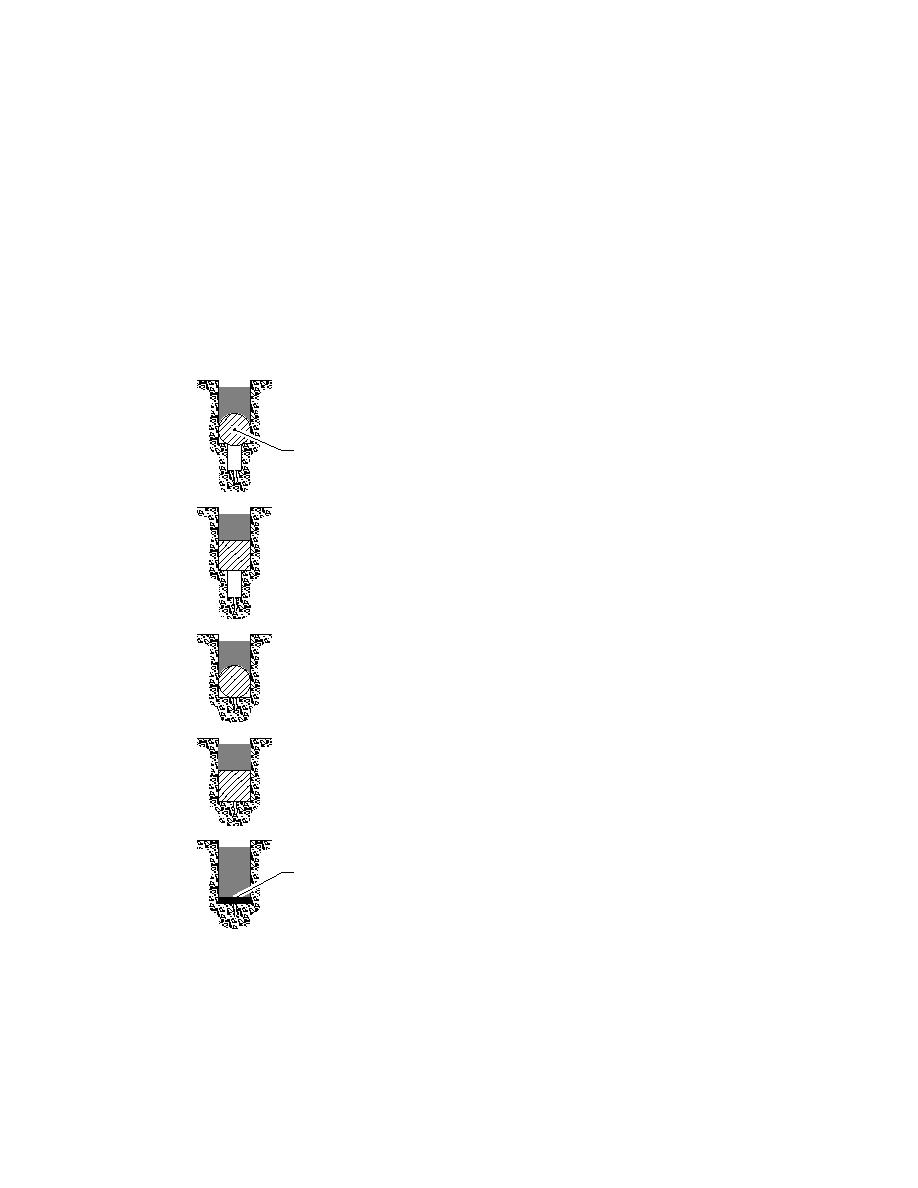

In an engineering design context, a pavement

joint or crack seal formed from a sealant can be

described as a long structure with a butt joint cross

section such as one of those depicted in Figure 7.

This figure shows typical seal cross sections in joint

and crack locations with variations of joint prepa-

ration, uses of backing rod and separating tape,

and seal geometries. Often in practice the construct-

ed cross sections will deviate from the ideal con-

figurations illustrated due to construction irregu-

Separating Tape

larities, backing rod installation or irregularities

in the crack or joint. For crack seals in particular,

it is also likely that there will be variations along

the length of the seal as a result of the meander of

the fracture in the pavement surface, and it may

Figure 7. Butt joint seal cross

sections in joint and crack loca-

be that a joint reservoir is not prepared during the

sealing operation and the seal is formed in the cav-

tions with different practical

ity of the crack. Although not quantified by realis-

variations of joint preparation,

uses of auxiliary materials and

tic structural analyses of seals, it is generally recog-

seal geometries.

nized that when there is significant deviation from

9

Previous Page

Previous Page