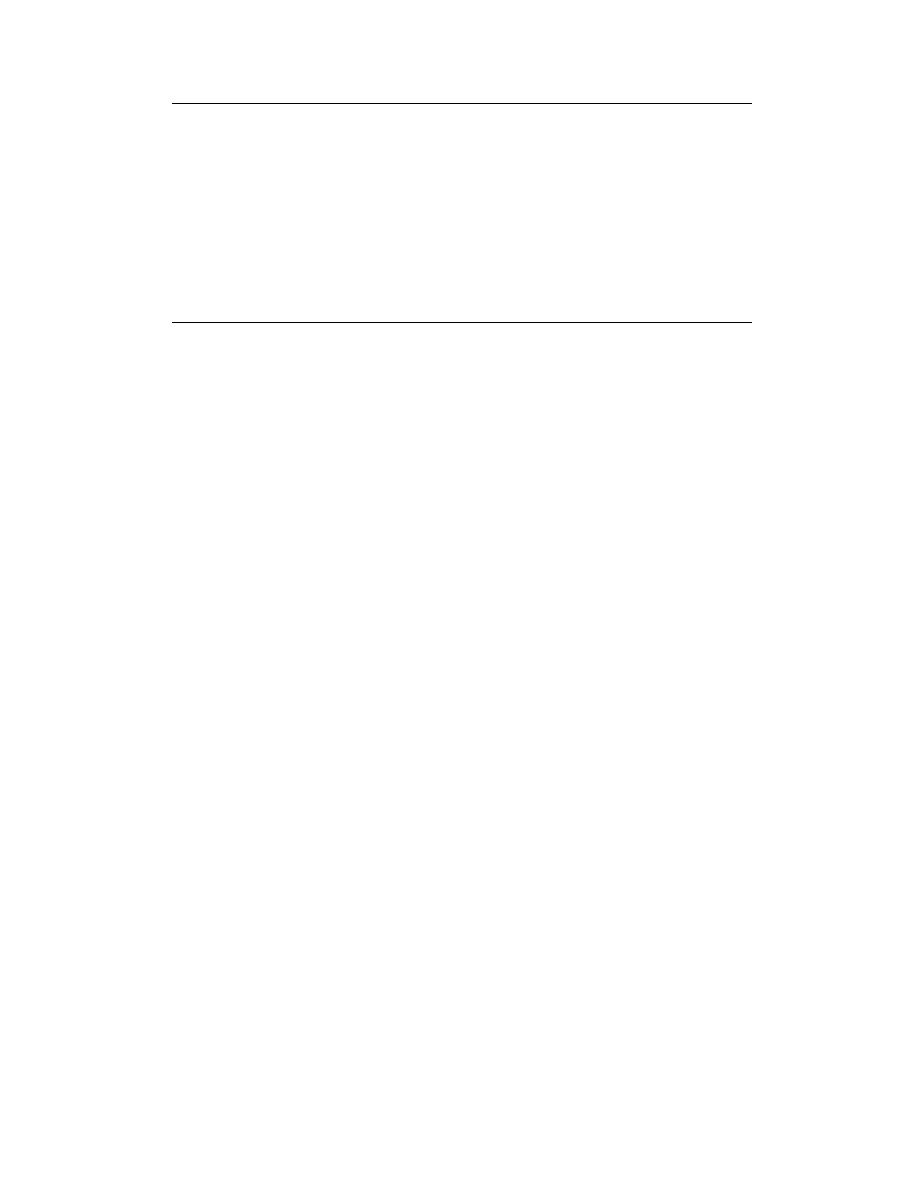

Table 1. Example sealant formulations, percentages by weight. (After Panek and Cook 1984.)

Urethane sealant: urethane polymer, 3545%; fillers, 3040%; colorants, 23%; thixotropic agents, 12%;

adhesion additives, 13%; plasticizers, 1525%; solvent, 04%

Silicone sealant, structural grade: silicone polymer, 6575%; silicone oil plasticizer, 515%; silica filler, 15

25%; curing agent, 35%; adhesive additive, 13% (lower modulus silicone sealants would have a higher

amount of silicone oil plasticizer and less cross-linking trifunctional silane complex)

Polysulfide sealant: polysulfide polymer, 3040%; various fillers, 3040%; plasticizers, 2025%; curing agents, 2

5%; adhesion additives, 13%; miscellaneous, 13%; solvent, 35%

Hot-poured rubber asphalt sealant: ground rubber (e.g., styrene-butadiene rubber ground to a 30-mesh

size), at least 25%; asphalt, remainder

Hot-poured polyvinyl chloride (PVC) and coal tar: PVC powder dispersed in a coal tar base

in which additives are blended and reacted with

sealant behavior in the context of the behavior of

the base elastomer(s) and cured to form the final

rubbers and elastomers since the material response

product, the asphalt and coal tar in such products

features of practical interest for sealing joints and

can be categorically regarded as fillers or plasti-

cracks are clearly revealed, and since the elasto-

cizers and adhesive agents, and the chemical and

meric qualities that a seal displays when subjected

physical reactions between these materials and the

to field loadings and conditions can be used to

rubber polymer can be viewed as a typical curing

judge the effectiveness of the sealant. In addition,

process that yields an elastomeric material. Indeed,

if a seal formed by an elastomeric-based sealant

it would be advantageous to consider all elasto-

does not behave elastically, e.g., if the seal deforms

meric-based sealants, including asphalt and coal

plastically or if it behaves with excessive viscous

tar rubbers, in a single context with respect to form-

behavior, the deviation from ideal elastomeric be-

ulation, so that engineers who select and use these

havior could be quantified and an assessment of

materials will have a mechanical framework that

the sealant could be made. This section describes

can be utilized to compare and contrast them.

the mechanical behavior of rubber-like materials

Different elastomers and elastomeric formula-

and low modulus sealants from a phenomenologi-

tions can attain their application configuration,

cal perspective. The section also describes the

cross-linking and mechanical properties through

hyperelastic material model, which is convention-

a variety of curing reactions and mechanisms. Seal-

ally used as a constitutive model for elastomeric

ants can be formulated to cure by chemical and

materials, and its potential application to sealants.

physical reactions and solvent release. The reac-

tions can be triggered, for example, by heat, as in

Phenomenological behavior of

the case of the hot-poured sealants, or by catalysts,

rubbers and elastomers

as in the case of moisture-induced cure of silicone

In unconfined loading configurations the de-

sealants.

formations of a rubber structure will generally be

dominated by shear distortions. This is because

the volume compressibility of elastomers and

elastomeric formulations of rubber-like materials

MECHANICAL BEHAVIOR

is, relative to the shear deformability, very low.

OF SEALANTS

Typically a rubber will have a bulk modulus that

In general, the commercially available, low

is orders of magnitude greater than its shear mod-

modulus sealants that are used for sealing joints

ulus. As a result, the material is constrained geo-

and cracks in pavements are formulated to behave

metrically by its own response to deform prima-

with rubber-like characteristics. That is, these mate-

rily by distortions. This is particularly true for the

rials are formulated so that a seal made from a low

base elastomer, and, depending upon the addi-

modulus sealant, loaded to a relatively large de-

tives, is likely to be the case for an elastomeric for-

formation, will return to its original shape and size

mulation.

upon unloading. For a description of the mechani-

The shear deformability of rubbers has been in-

cal properties of sealants it is helpful to consider

vestigated using different loading and test speci-

3

Previous Page

Previous Page