10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

d/w

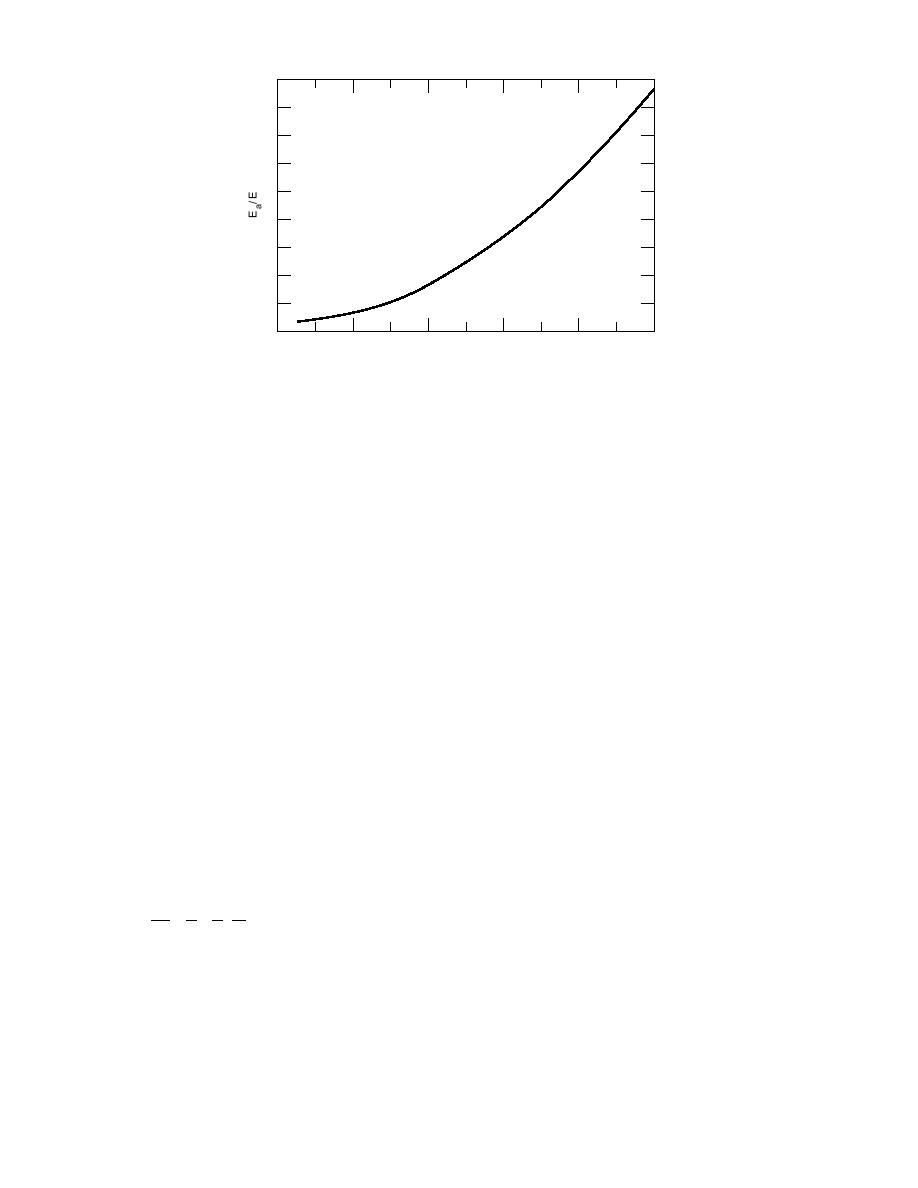

Figure 8. Ratio of apparent Young's modulus to Young's modulus of

the material, Ea/E, of a rubber block in the configuration of a long

butt joint seal, in relation to the shape factor d/w. (From Gent and

Lindley 1959.)

formation pattern deviated from the parabolic

tios of d/w less than 1, the apparent modulus of a

shape and the nominal strain distribution along

seal can approach a value that is 4/3 the sealant

the parabolic surface varied slightly from a "uni-

modulus, yet the apparent modulus can increase

dramatically with increasing d/w ratios. This in-

form" nominal strain. The calculation of a nomi-

formation could be used in the design choice of

nal strain that Tons suggested, and the use of the

d/w to ensure that stresses in the seal and at the

calculations to compare the movement capability

adhesive interface will not be excessive, i.e., to en-

of seals formed with different shape factors, is an

sure that a seal formed from a low modulus seal-

approach that has been incorporated into design

ant will not respond with a high stiffness. The re-

manuals (ACI 1993) and used extensively by prac-

lation provides a clear structural rational for the

ticing engineers.

need to maintain control over shape factors in

Another publication from 1959 describes a sim-

crack-sealing jobs through such means as rout and

ple analytical solution for shape factor design that

seal or saw and seal techniques. Gent and Mien-

is based on structural mechanics theory. Gent and

ecke (1970) presented similar solutions for bend-

Lindley (1959) presented results of elasticity analy-

ing and apparent shear joint movements, which

ses and experiments designed to assess the effect

could also be used for joint seal shape design. Gent

of a shape factor on the apparent modulus of rub-

and Lindley (1959) further showed that the eq 3

ber blocks, i.e., the stiffness of the blocks, in butt

relation might not apply directly to volume-com-

joint seal configurations under compression loads.

pressible rubber formulations, although they sug-

They showed that the apparent Young's modulus

gested that the relation could be modified to pre-

Ea of a rubber block in the configuration of a long

dict the response of such compounds. Chalhoub

butt joint seal, in relation to the Young's modulus

and Kelly (1991) presented an instructive deriva-

of the material E, the width of the joint w and the

tion of the eq 3 relationship, and also considered

depth of the seal d, can be approximated by

volume compressibility.

2

Ea 4 1 d

For an approximate analysis of the larger de-

= + .

(3)

3 3 w

formation compression or extension responses of

E

the rubber in a butt joint seal configuration, Gent

and Lindley (1959) utilized an elasticity-based so-

The relation is illustrated in Figure 8. It was de-

lution (Treloar 1975) of the stressstrain response

rived for volume-incompressible rubbers at small

of a rubber in pure homogeneous compression or

deformations, and was shown to compare well to

extension, with the Young's modulus replaced with

the experimental behavior of compressed rubber

the apparent Young's modulus. From the solution

blocks. Applying the relation to joint seals, for ra-

12

Previous Page

Previous Page