8

Test programs that incorporate these experimen-

tal configurations are sometimes devised to investi-

a.

gate material behavior, to calibrate phenomeno-

6

logical constitutive models of rubber elasticity be-

havior that can be used for material and structural

response calculations, and to verify predictions

4

made using the constitutive models.

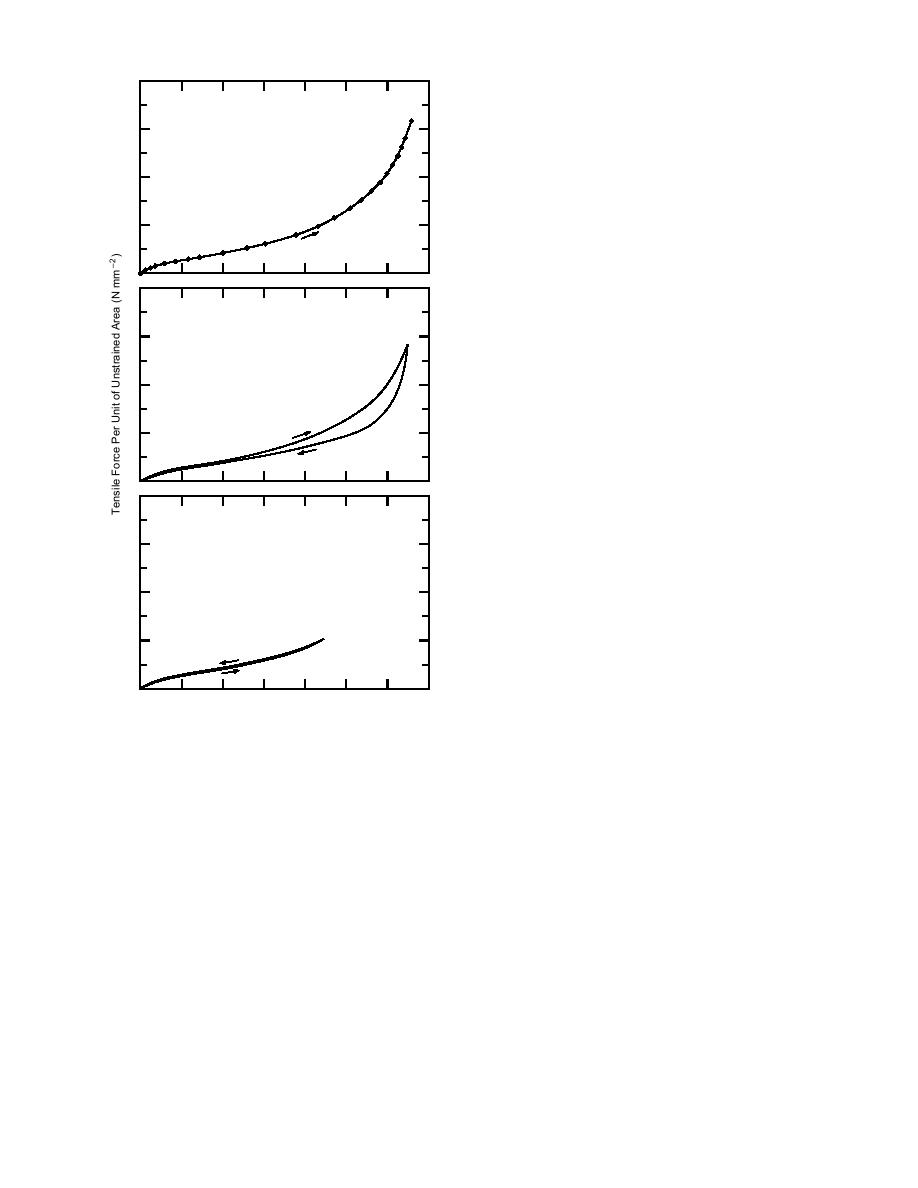

Simple tension tests of elastomers yield re-

2

sponse curves like those shown in Figure 1. The

figure relates force per unit of unstrained area to

extension ratio, which is defined as the deformed

0

specimen length normalized by the undeformed

8

specimen length. The data in the figure are for a

vulcanized natural rubber tested at room tempera-

b.

ture, and are published by Treloar (1975).

6

Figure 1 includes the force-extension ratio re-

sponses measured in three simple tension tests.

4

Curve (a) illustrates the response of a specimen

that was loaded to failure, whereas curves (b) and

(c) illustrate the responses of specimens that were

2

loaded and unloaded without failure. Based on the

curves (b) and (c) Treloar (1975) noted that up to

an extension ratio of about 5.5 the material response

0

was substantially reversible, but that loading to a

8

higher extension resulted in significant hysteresis.

c.

Curve (c) illustrates clearly the low resistance, high

6

extension, nonlinear elastic response that is the

characteristic feature of the behavior of rubber ma-

terials. For example, it is roughly the behavior of

4

the material of a rubber band when stretched.

Implicit in this description of an elastomer is a

temperature range for which rubber-like behavior

2

occurs. The transition from rubbery to glassy be-

havior (the glass transition) is often characterized

0

by a single temperature, although, unlike a crys-

1

2

3

4

5

6

7

8

talline material, the mechanical behavior changes

Extension Ratio

gradually over a temperature range. The transition

Figure 1. Results from three simple tension tests of vul-

occurs because the chains of the amorphous mo-

canized natural rubber. (After Treloar 1975.)

lecular network become less flexible with decreas-

ing temperature until the structure is rigid. Figure 2

men configurations. Traditionally, for obtaining ma-

illustrates the changes in the load and extension

terial stress-strain data under homogeneous stress

response that are typically observed in polymers

and deformation conditions, load and deforma-

that are tested in simple tension tests at different

tion responses have been measured in simple ten-

temperatures. Only above the temperature range

sion, equibiaxial tension and pure shear tests. Tor-

of the glass transition will a polymer in simple ten-

sion tests, which inherently generate inhomogen-

sion tests deform with homogeneous strains and

eous stress and deformation conditions, can pro-

behave like an elastomer (Ward 1983). Within and

vide material stressstrain data as well (Penn and

below the transition range the deformation will not

Kearsley 1976), by using a technique for calculat-

be homogeneous, and ductile or brittle failure can

ing material stressstrain data from the measured

occur. The figure illustrates that a material in-

torque and axial force of the torsion sample (Kears-

tended for use as an elastomer will actually be-

ley and Zapas 1980). For standard comparative

have as a stiff and perhaps brittle material when

measures of material properties the simple tension

its temperature is below the glass transition tem-

configuration is often used (e.g., ASTM 1991d).

perature.

4

Previous Page

Previous Page