frame surrounding the PV module and glazing was very

tight and had only slight movement when a twisting

motion was applied. The glazing, panel back, and junc-

tion box were all free of defects.

Solarex, MSX-50

The Solarex panels also showed no signs of any

structural defects. The aluminum frame experienced

very little flex when a twisting motion was applied. The

aluminum frame was tight to the PV module and glaz-

ing surface. The glazing, panel back, and junction box

were all free of defects.

Measure of PV panel flex

To determine the flex (rigidness) of a PV panel, a

simple fixture was constructed. It held three corners of

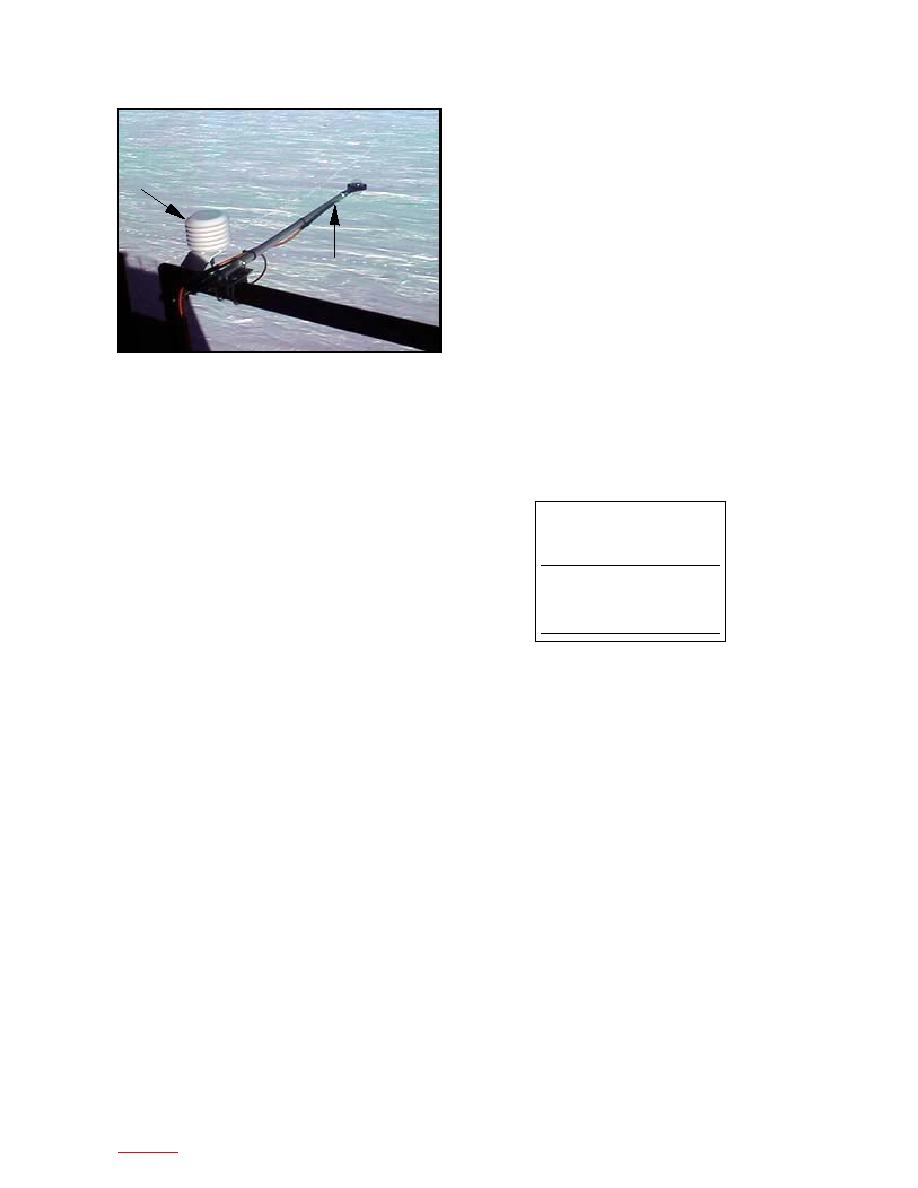

Figure 10. Temperature sensor with radiation shield (left

arrow) and Q-7 net radiometer in horizontal position (right

the PV panel in a fixed position, while the fourth cor-

arrow).

ner was left free to allow the PV panel to be pulled to

simulate a twisting motion. Each PV Panel that was

Ambient air temperature

tested had approximately 8 lb (35.6 N) of tension

The ambient air temperature sensor (Fig. 10) uses

applied to the free corner. The deflection attributable

the same thermistor (107B temperature probe) as does

to the twisting motion was then recorded (Table 3).

the PV panel temperature sensor. Like the PV panel heat-

ing sensor, the ambient air temperature sensor was

polled by the CR10X's P4 instruction. Unlike the PV

Table 3. PV panel flex.

panel temperature sensor, a solar radiation shield has

PV

Deflection

been added to ensure that the true ambient temperature

panel

(in.)

(cm)

was measured.

KYOCERA

0.375

0.9525

ASE Americas

0.500

1.27

RESULTS

Solarex

0.750

1.905

PhotoComm

1.125

2.858

PV panel inspection prior to installation

KYOCERA, LA-51

Processed data

No obvious defects were found in the KYOCERA

All data sent from the South Pole from 25 November

PV panel. The aluminum frame surrounding the PV

1997 to 2 December 1998 have been processed into

module and glazing exhibited great strength. When a

one data file. That data file has been analyzed to pro-

twisting motion was applied to this PV panel, the alu-

vide following.

minum frame barely flexed. The glazing, panel back,

Performance of all PV panels from 25 November

and junction box were all free of defects.

1997 through 2 December 1998.

Performance of all PV panels over 24 hours on a

PhotoComm, Inc., DV-50-AL

high-visibility day.

On all four of the PhotoComm, Inc., panels that we

Performance of all PV panels over 24 hours on a

inspected, the gasketed seal between the glazing and

low-visibility day.

aluminum frame showed signs of failure. The gasketed

Net radiometer readings from 25 November 1997

seal was pulling out of the corners between the glazing

to 2 December 1998.

surface and aluminum frame. Each panel showed some

Situation report (SITREP) data, 19971998.

signs of aluminum frame weakness. The corner connec-

tions of the frame were loose and allowed considerable

Overall PV panel performance

movement when a twisting motion was applied. Three

Figures A1A16 were created to show the perfor-

of the frames showed signs of abuse; they had dents

mance of each PV panel. PV power output and PV panel

and or were bent. The glazing, panel back, and junc-

temperature are parameters of interest. The readily avail-

tion box were all free of defects.

able PV power coincided with the sun declination an-

gle. At the highest sun declination angle (23.5), the

ASE Americas, ASE-50-AL

PV panels exceeded or approached their rated PV power

The ASE Americas' panels are well built. No defects

output. As available PV power increased, PV panel heat-

were detected from a visual inspection. The aluminum

7

to contents

Previous Page

Previous Page