tion, as determined by a reference method, and,

Table 9. Percent recoveries and relative standard devia-

for one sample set, only greater than values (those

tions for performance evaluation materials analyzed dur-

above method calibration range) were reported for

ing the field trial.

both the HM 2000 and visual method. For the 13

Technology developer

remaining sample sets, the reference method and

CRREL

Visual

HM 2000

both the HM 2000 and visual results were com-

Sample

% Recovery % Recovery %Recovery

pared by looking at the percent difference (%D)

No./ID

(% RSD)*

(% RSD)

(% RSD)

among them (Fig. 2). For both matrices, at least half

1. Gasoline

the %D values were greater 100%, indicating that

Soil, SG-1, 2, 3 & 4

99

160

310

both the visual and HM 2000 methods tend to give

(200 mg TPH/kg)

(8.6)

(38)

results that are biased high, compared to the refer-

Water, WG-1, 2, 3 & 4

100

430

480

ence method.

(1.0 mg TPH/L)

(7.0)

†

2. Diesel

DISCUSSION

Soil, SDM-1, 2, 3 & 4

--

300

270

(401 mg TPH/kg)

(56)

The procedures developed for using the Hanby

Test Kits and HM 2000 to estimate the TPH con-

Soil, SDM-25, 26, 27 & 28

--

270

290

centrations in soil and water matrices are easy to

(2480 mg TPH/kg)

(35)

learn and use; however, some changes and im-

* % Relative standard deviation

provements are recommended. The current prac-

† Only two of the four replicates were analyzed; no estimate was

tice for collecting and preparing soil samples sus-

pected to be contaminated with gasoline must be

changed. The high vapor pressures (i.e., low boiling

and for one out of seven by the HM 2000 method (Table

points) of many of the hydrocarbons in gasoline make

10). However, in one instance, for the visual method,

the matrices contaminated with this petroleum product,

this was clearly fortuitous, as the replicate values dif-

particularly soils, susceptible to volatilization losses

fered by a factor of 3.9 (Appendix A, Table A1; SG-20

when samples are collected and prepared (Hewitt et al.

and -21). The reference method yielded an average TPH

concentration within 20% of the expected value for

1995). For this reason, to limit exposure during collec-

tion, a modified syringe or similar coring device should

three of the four duplicate sets analyzed (Table 10).

be used rather than a spoon or spatula. In addition, in-

For the PE samples, the %RSD ranged from 35 to

stead of adding a soil to a beaker, weighing, and then

56% for the HM 2000. In contrast, the %RSDs were below

adding the extraction solvent, as currently instructed,

10% for the reference method of analysis. The RPDs

soil samples should be transferred with special precau-

for the matrix spike sample duplicates and field sample

tions being taken to limit exposure, and placed directly

duplicates were also used to assess precision. For the

into VOA vials containing the appropriate extraction

matrix spikes, the RPDs ranged up to 140%, and were

solvent. This approach to handling soils contaminated

on average 35%, for the HM 2000 method; in contrast,

with gasoline was used in this study, and is consistent

with the reference method, they ranged up to 28%, and

with the guidance given in Method 5035 and D 4547-

were on average less than 10% (Table 10 and 11).

98 (U.S. EPA 1986, ASTM 1998).

Of the field samples, 11 co-located soil samples and

To reuse the cuvettes, the Friedel-Crafts aklyation

8 replicate water samples contaminated with gasoline

by-products (e.g., AlCl3) must be removed, and the ves-

were analyzed by the HM 2000, visual method, and a

reference method (App. A, Tables A1 and A2). Of these

sel washed and dried. However, when water is used to

19 sample sets, five had concentrations below detec-

rinse these by-products from the cuvettes, a reaction

4

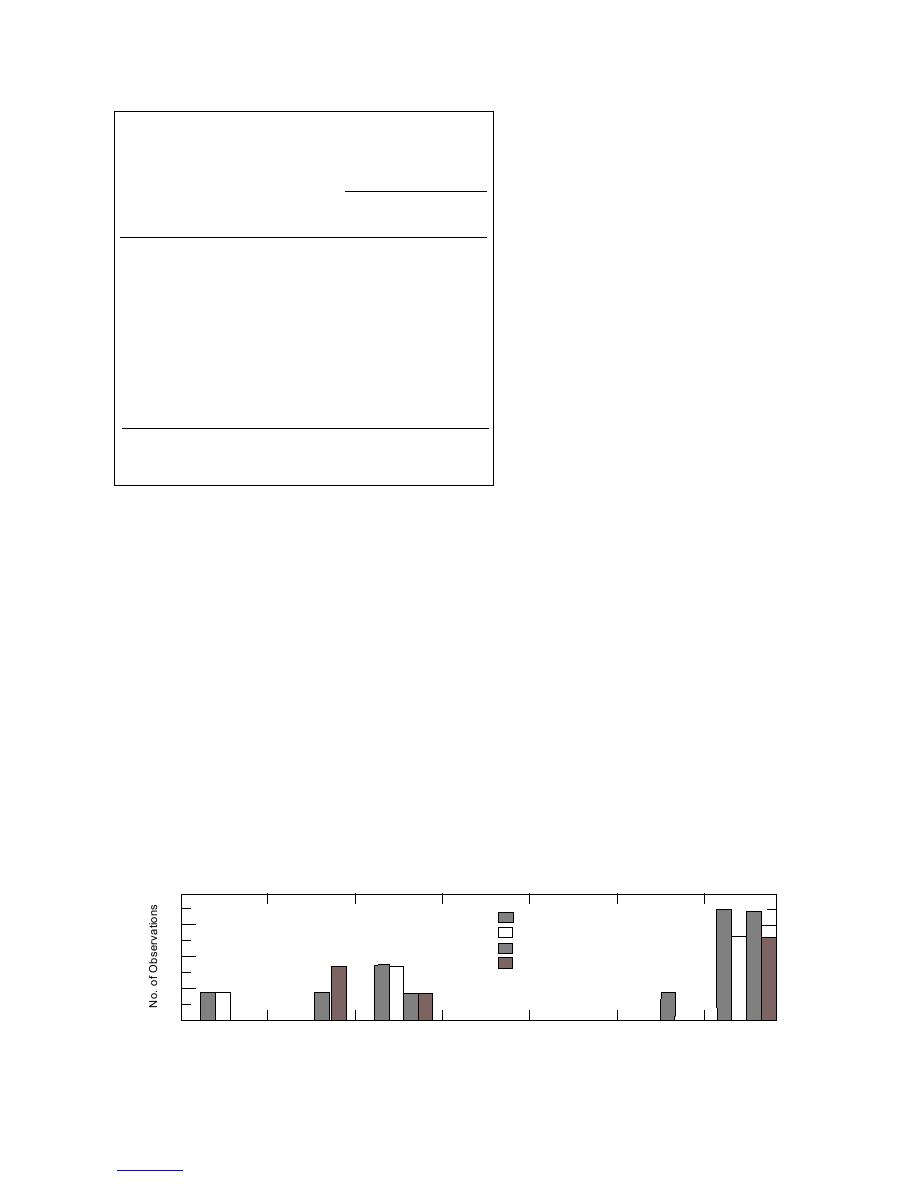

Visual, Soil

3

Visual,H20

HM 2000, Soil

2

HM 2000, H20

1

0

100 to 51

50 to 26

25 to 0

0 to 25

26 to 50

51 to 100

> 100

Figure 2. Range of percent difference (%D) values for TPH in soil and water field samples obtained

by the visual and HM 2000 methods as compared to the reference method.

8

Previous Page

Previous Page