extraction was performed, as

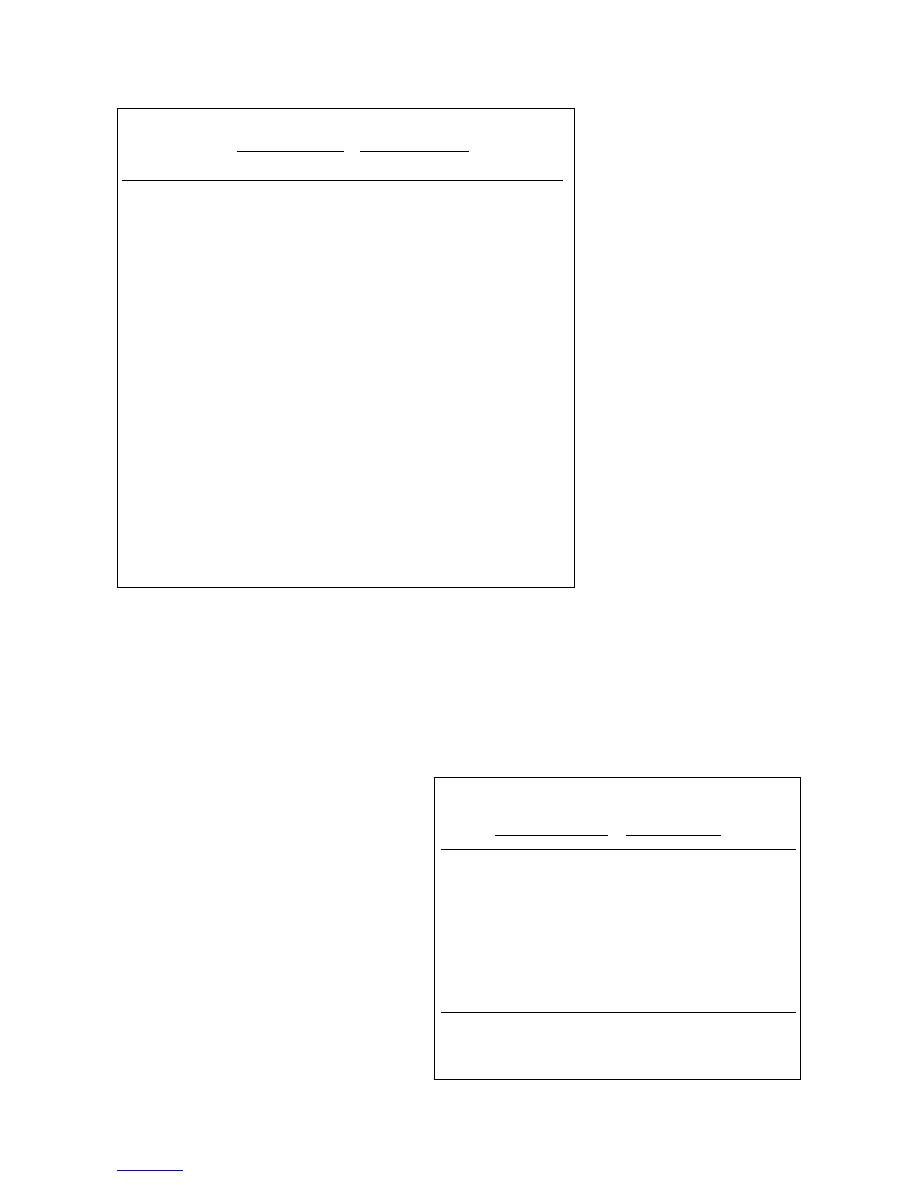

Table 2. Laboratory prepared matrix spike samples.

described previously. After a 4.2-mL

Standard

Sample

aliquot of extraction solvent was re-

Conc.

Vol.

Moisture

Target

moved and placed into a cuvette, the

(mg TPH/mL) (L)

Matrix

Wt. or Vol.

(%)

concentration

funnel was cleaned, and a second set

I. Gasoline Soils

of samples was taken from the 1-L

Silt/Clay

52

10

5.0 g

10

100 mg TPH/kg

bottle. These replicate samples were

Silt/Clay

260

10

5.0 g

10

520 mg TPH/kg

taken approximately 20 minutes

Clay

52

10

5.0 g

10

100 mg TPH/kg

after the first set. For the reference

Clay

260

10

5.0 g

10

520 mg TPH/kg

Silt/Clay/Sand

100

10

5.0 g

15

200 mg TPH/kg

analysis method, a 2- or 10-mL vol-

Silt/Clay/Sand

520

10

5.0 g

15

1000 mg TPH/kg

ume was removed from the VOA

Silt

100

10

5.0 g

20

200 mg TPH/kg

vials to a small graduated cylinder

Silt

520

10

5.0 g

20

1000 mg TPH/kg

and then transferred to an analysis

Silt/Clay/Sand

10

10

5.0 g

16

20 mg TPH/kg

vessel (20-mL VOA vial). When

II. DieselSoils

only a 2-mL volume of sample was

Slit/Clay

84

12.5

5.0 g

20

210 mg TPH/kg

transferred, 8 mL of organic free wa-

Silt/Clay

340

12.5

5.0 g

20

850 mg TPH/kg

ter was present in the VOA vial. Care

Slit

84

12.5

5.0 g

20

210 mg TPH/kg

was taken during these transfers to

Silt

340

12.5

5.0 g

20

850 mg TPH/kg

limit exposure while pouring;

Silt/Clay/Sand

84

12.5

5.0 g

15

210 mg TPH/kg

Silt/Clay/Sand

340

12.5

5.0 g

15

850 mg TPH/kg

however, some losses were expected

because of these transfer steps.

III. Gasoline water

Water

7.4

50

1050 mL

--

0.35 mg TPH/L

Field

Water

7.4

150

1050 mL

--

1.0 mg THP/L

For the technology demonstration

Water

7.4

700

1050 mL

--

4.9 mg TPH/L

Water

7.4

2000

1050 mL

--

14 mg THP/L

trial, 90 samples (52 field and 38

Water

6.9

300

1050 mL

--

2.0 mg TPH/L

quality assurance [QA]) samples

Water

6.9

3.0

1050 mL

--

20 mg TPH/L

were distributed for on-site visual

and HM 2000 analysis (Table 3). The

field demonstration used a single and double blind for-

glass ampoules were heat-sealed using a propane torch

and then stored in a refrigerator (4 2C) for 2 to 7

mat. On site, the technology developer was only informed

of the type of TPH contamination, and in the case of soil,

days to allow the analytes to sorb to the matrix. If held

the sample weight. At the same time that samples were

longer than this, the samples were stored in a freezer

(12 5C) until they were prepared for analysis. For

collected and prepared for distribution for on-site analy-

sis, co-located samples or sample splits were taken for

this preparation, an ampoule was placed into a VOA

off-site analysis. A description of the field sampling and

vial containing an extraction solvent. Once the VOA

subsampling methods used during this technology dem-

vial was capped, it was shaken, causing the ampoule to

break so that the spiked soil could be dispersed into

the extraction solution. Soils prepared for the visu-

Table 3. Quality assurance and field samples distributed

al and HM 2000 analysis methods were dispersed

during the field trials.

over a 30-minute period by intermittent manual

Field

Matrix

shaking before 4.2 mL of the binary solvent was

Bulk* Spike dup. PE† Total

Samples Duplicate

decanted into cuvettes.

I. Gasoline (b.p. 60170C)

For the gasoline-fortified water samples, spikes

Soil

9

2

1

2 (4)**

4

20

were added to 1050 mL of organic free water (Milli-

Water

6

1

1

2 (4)

4

16

pore) in a 1-L glass bottle with a Teflon-lined sep-

II. Diesel/bunker C (b.p. 160400C)

tum cap. These samples were made and analyzed

on the same day. After fortification, the bottle was

Soil

12

2

1

2 (4)

8

27

Water

12

1

1

2 (4)

--

18

inverted several times to mix the contents and then

allowed to stand for several minutes. For the refer-

III. Motor oil (b.p. 315540C)

ence analysis, a 20-mL glass bottle with a Teflon-

Soil

6

1

--

1 (2)

--

9

lined septum cap was completely filled and imme-

* Blank.

diately capped. For the test method, 500 mL was

† Performance evaluation samples.

gently poured into a separatory funnel. Carbon

** Numbers in parenthesis are the total number of matrix spike

tetrachloride (5 mL) was added to the funnel and the

samples.

4

Previous Page

Previous Page