600

400

200

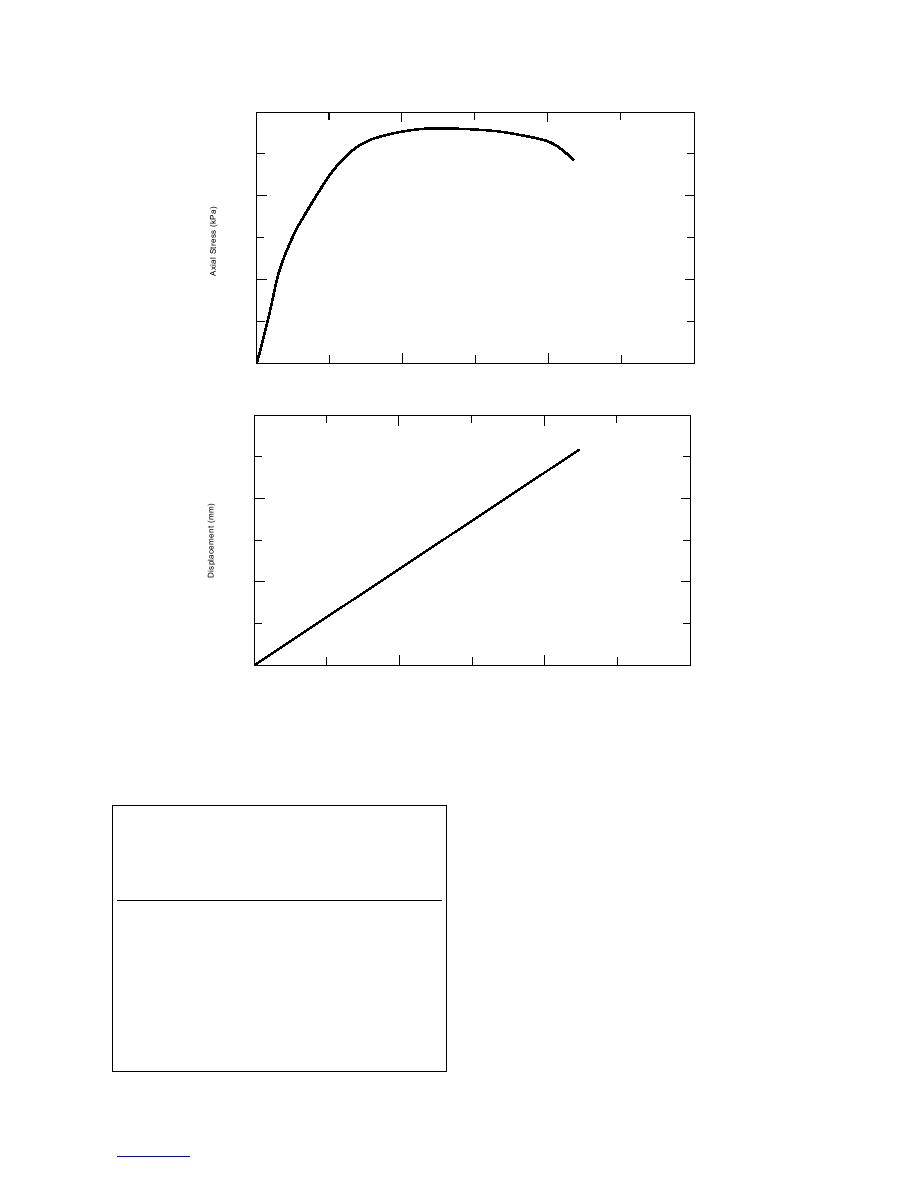

a. Axial stress

0

50

100

150

0

Time (seconds)

600

400

200

b. Displacement.

0

50

100

150

0

Time (seconds)

Figure 19. Typical measurements (100% natural, σ3 = 73 kPa).

to shift upward on the same curve as the 36 kPa, unlike

Table 12. Shear strength material properties from

the distinct difference seen with the 150-mm-diameter

large-scale tests (300-mm φ).

sample results (Fig. 22).

Test

The effect of void ratio and percentage of crushed

σ3f

(τmax)f

(%

Void

c

material in the aggregate mixture on the mixture's shear

φ

crushed)

ratio

(kPa)

(kPa)

(kPa)

strength is presented in Table 14 and Figure 23. For the

(51)

300-mm samples, shear strength decreases rapidly with

100 (rep 1)

0.158

35

279

100 (rep 2)

0.089

73

560

increasing void ratio. A similar but less rapid response

51

75 (rep 1)

0.155

37

273

51

than that seen with the 300-mm-diameter samples is

75 (rep 2)

0.158

69

385

seen with the 150-mm samples when the confining pres-

50

50 (rep 1)

0.190

34

151

15

sure is 70 kPa. At the lower confining pressure of 36

50 (rep 2)

0.147

72

273

50 (rep 3)

0.115

37

339

kPa, shear strength is unaffected by the void ratio (Fig.

25 (rep 1)

0.159

37

283

23). As with the maximum shear stress, the correlation

25 (rep 2)

0.085

70

578

between the percent crushed aggregate and shear strength

31

0 (rep 1)

0.137

33

265

129

is poor (Fig. 23).

0 (rep 2)

0.129

73

308

16

Previous Page

Previous Page