60

0

75

50

75

25

100

50

40

0

20

300-mm Samples

150-mm Samples

0

0.000

0.050

0.100

0.150

0.250

0.200

0.300

Void Ratio

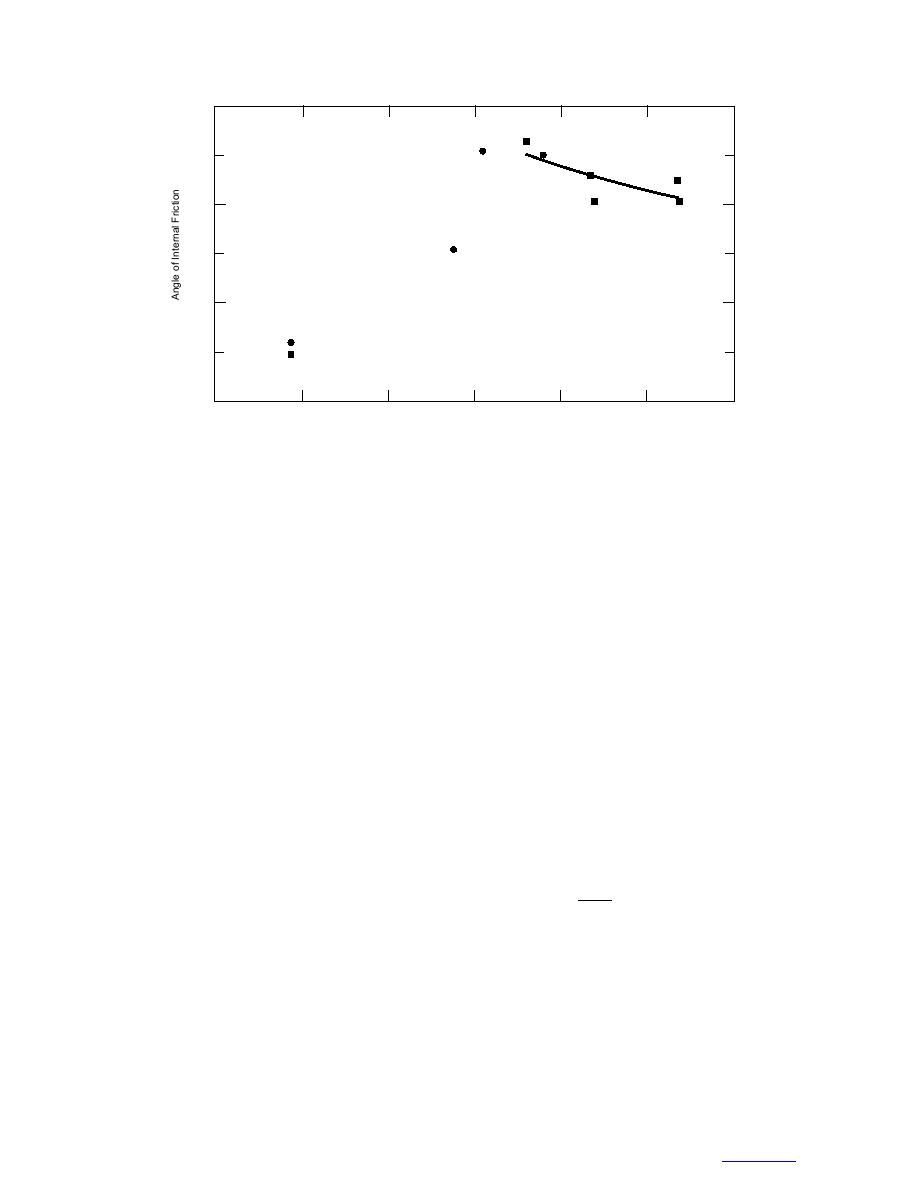

Figure 24. Effect of void ratio on the angle of internal friction.

Approximately 23 kg of aggregate was required for the

original PI required that aggregates be separated into

test. From the 23-kg sample, we were able to get approx-

three sizes: passing the 3/4-in. and retained on the 1/2-

imately 6 kg of aggregates, which were separated into

in. sieve; passing the 1/2-in. and retained on the 3/8-in.

coarse and fine fractions. Coarse aggregates passed the

sieve; and passing the 3/8-in. and retained on the No. 4

38-mm sieve but were retained on the 4.75-mm sieve.

sieve. For each size, the test involves tamping uniform

Fine aggregates passed the 4.75-mm sieve but were

aggregates into a mold in three equal layers using a

retained on the 0.6-mm sieve.

standard tamping rod with 10 strokes per layer. The

The coarse aggregates were compacted in three equal

process was repeated with 50 strokes per layer. Based

layers in a steel cylindrical mold with an inside diame-

on the percentage of voids at two compaction levels, PI

ter of 150 mm and an inside height of 178 mm (Fig.

was calculated from

26). The layer had ten drops evenly distributed over

PI = 1.25V10 - 0.25V50 - 32

(11)

the surface. The compaction effort was applied through

a rounded rod with a hemisphere diameter of 16 mm

where V10 = % voids in aggregates, 10 strokes per layer,

and a length of 610 mm. Each drop was made by hold-

and V50 = % voids in aggregates, 50 strokes per layer.

ing the rod vertically with its rounded end 51 mm above

Details on the development of the test method can

the surface of the aggregate. At the end of the third

be found in Huang (1965) and Janoo (1998).

layer compaction, the aggregate and mold was weighed

Breaking the aggregates into various particle sizes

and the amount of coarse aggregate to fill the mold was

is time consuming and expensive. A study conducted by

determined.

Michigan Transportation Commission (1983) showed the

From the weight, the volume of voids was calculated

following:

from

1. PI was more dependent on the aggregates' geo-

metric properties than on gradation. PI values were sig-

W

nificantly higher for crushed than for natural aggregates.

V10 = 1 - 10 100

(12)

2. PI tests conducted on the total mixtures produced

GsbV

similar relative differences between crushed and natu-

where V10 = % voids in aggregates at 10 strokes per

ral aggregates (Fig. 25).

layer

3. The PI showed less variation if based on the voids

W10 = average weight of aggregates in the mold

from the 10-blow compactive effort. The additional 50

Gsb = bulk dry specific gravity

blows were unnecessary.

V = volume of mold, mL.

Based on the results from the Michigan study, we

decided to use the modified Michigan Test Method for

Based on the Michigan study, the modified PI is esti-

determining PI. Tests were conducted on the 0, 25, 40,

mated from Figure 27 or from

50, 60, 75, and 100% crushed aggregate mixtures.

19

Previous Page

Previous Page