Table 6. Testing sequence for VAOT base/subbase mate-

Table 7. Test sample densities, moisture contents,

rial (150-mm-diameter sample).

and void ratios (300-mm-diameter sample).

Confining Maximum Cyclic

Contact

Number of

Optimum

Sequence

pressure axial stress stress

stress

load

%

density

Test density

Void ratio

no.

(kPa)

(kPa)

(kPa)

(kPa)

applications

(kg/m3)

Rep 1

Rep 2

Rep 1 Rep 2

crushed

0

103.4

103.4

93.1

10.3

5001000

100

2319

2288

2433

0.158

0.089

1

20.7

20.7

2.7

2.1

100

75

2346

2288

2288

0.155

0.158

2

20.7

41.4

5.4

4.1

100

50

2349

2218

2376

0.190

0.1151

3

20.7

62.1

8.1

6.2

100

25

2381

2277

2376

0.159

4

34.5

34.5

31.0

3.5

100

0

2404

2325

2348

0.137

0.129

5

34.5

68.9

62.0

6.9

100

6

34.5

103.4

93.1

10.3

100

Optimum

7

68.9

68.9

62.0

6.9

100

moisture

Target moisture

8

68.9

137.9

124.1

13.8

100

%

content

content (%)

9

68.9

206.8

186.1

20.7

100

crushed

(%)

Rep 1

Rep 2

10

103.4

68.9

52.0

6.9

100

11

103.4

103.4

93.1

10.3

100

100

6.0

5.4

4.9

12

103.4

206.8

186.1

20.7

100

75

5.0

5.0

5.0

13

137.9

103.4

93.1

10.3

100

50

4.6

4.6

4.6

14

137.9

137.9

124.1

13.8

100

25

5.0

5.1

15

137.9

275.8

248.2

27.6

100

0

6.0

4.9

4.9

1000

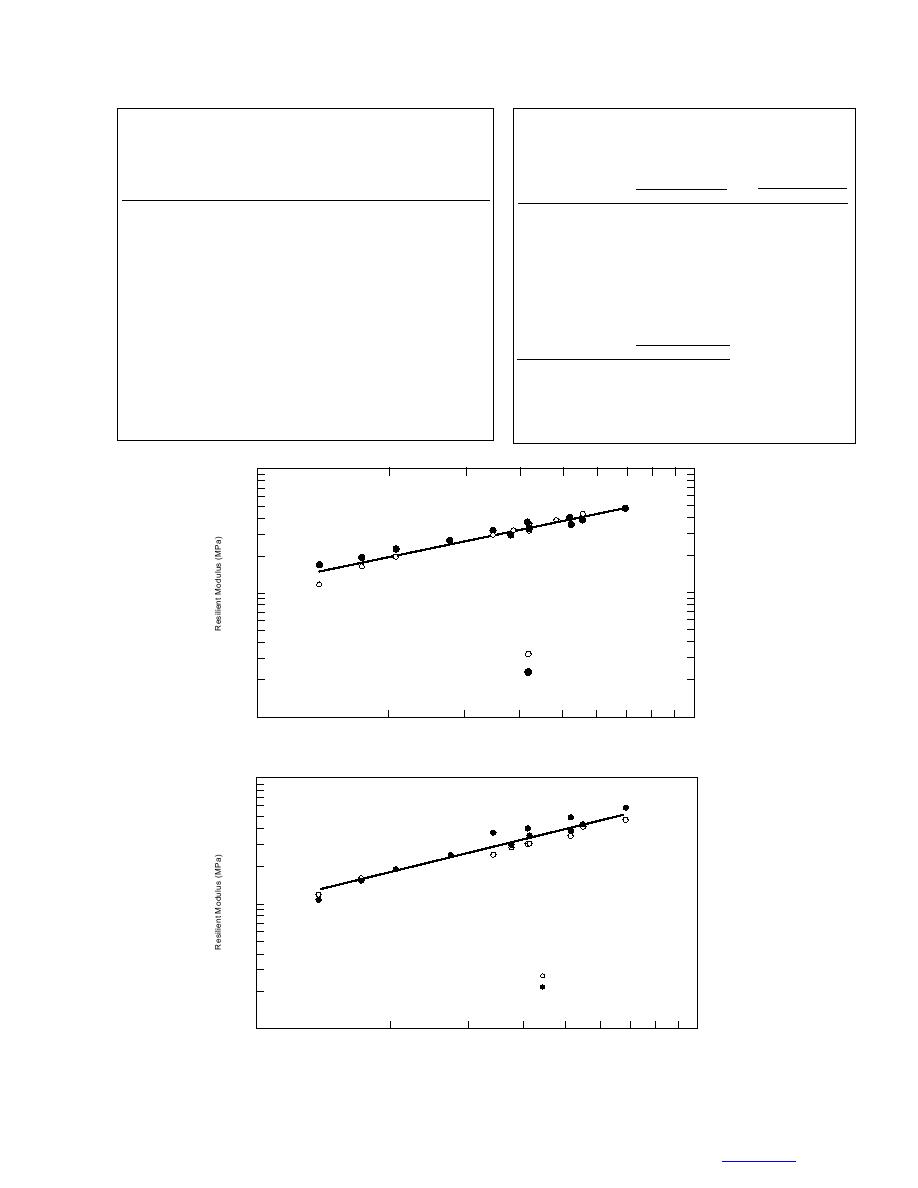

y=2.1258x0.7248

R2 = 0.99

100

100% Crushed (e = 0.158)

100% Crushed - 2nd (e = 0.089)

10

100

1000

Bulk Stress, θ (kPa)

a. 100% crushed aggregates.

1000

y = 0.9964x0.8494

R2 = 0.96

100

75% Crushed (e = 0.155)

75% Crushed - 2nd (e = 0.158)

0

1000

Bulk Stress, θ (kPa)

100

b. 75% crushed aggregates.

Figure 14. Resilient modulus as a function of bulk stress.

11

Previous Page

Previous Page