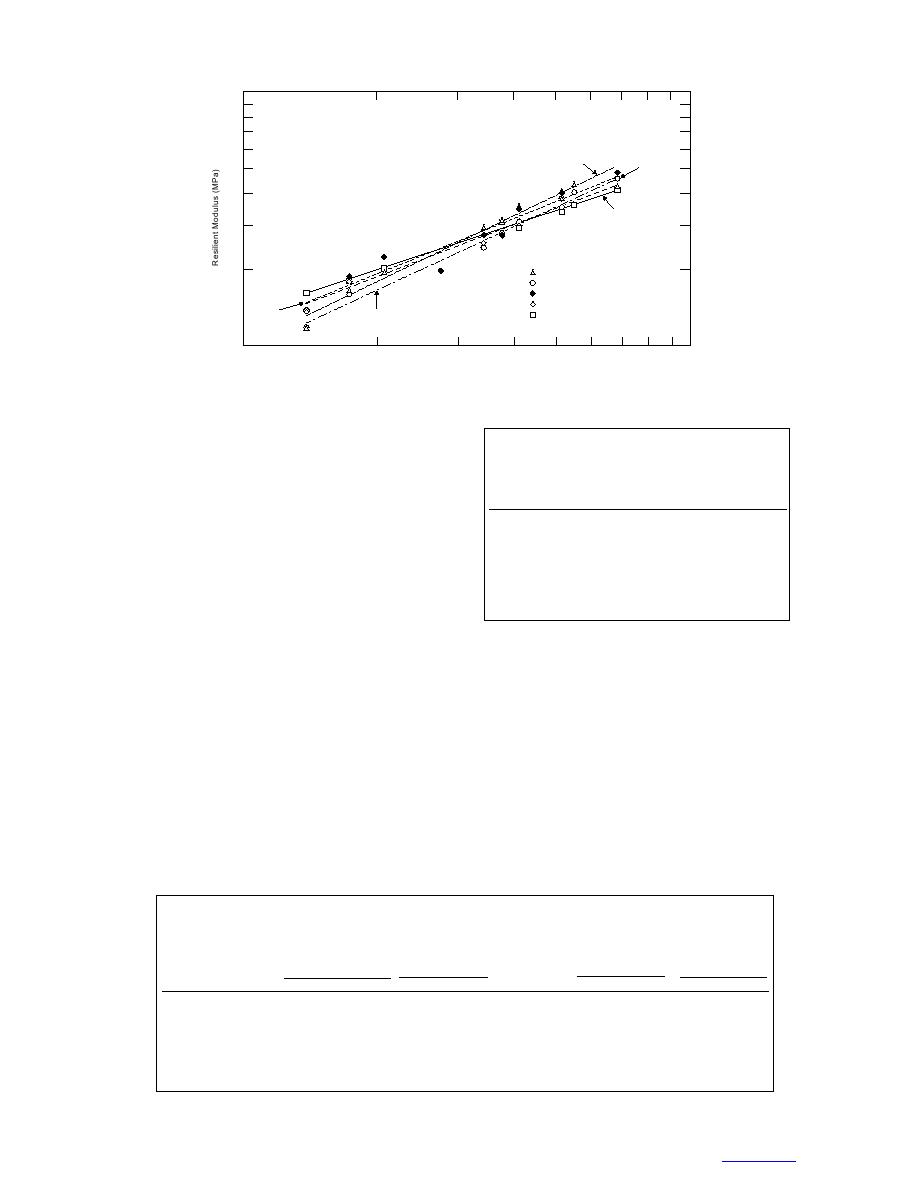

1000

100%

25%

0%

100% Crushed (e = 0.158)

75% Crushed (e = 0.155)

50% Crushed (e = 0.152)

25% Crushed (e = 0.158)

50%

0% Crushed (e = 0.137)

75%

100

100

1000

Bulk Stress, θ (kPa)

Figure 15. Resilient modulus as a function of bulk stress and aggregate angularity.

the reverse is true. The difference between the resilient

Table 8. Regression coefficients k1 and k2 for

modulus for crushed and natural material is small,

(Mr θ) model (300-mm-diameter samples).

approximately 10%. This small difference can be attrib-

%

uted to the low deviator stresses used and, in turn, the

R2

crushed

Void ratio

k1

k2

materials are in the linear range. In conclusion, the effect

of crushed material in a base course mix may not be

100

0.089 0.158

4.2517

0.7248

0.99

75

0.157

1.9928

0.8494

0.96

significant.

50

0.115

9.9406

0.6217

0.87

For the

50

0.190

1.7019

0.8075

0.96

25

0.158

5.2811

0.6753

0.98

Mr = k1θk2 (MPa)

(10)

0

0.129

8.4134

0.6769

0.92

0

0.137

9.2203

0.5814

0.99

model, coefficients k1 and k2 (Table 8) were obtained

COV of 8%.

from a regression analysis using a power function.

Average density of the large-scale samples was 2316

A similar analysis was conducted with results from

kg/m3, whereas average density of the 150-mm-diameter

the 150-mm-diameter test samples (Fig. 16). The opti-

samples was 2179 kg/m3, a difference of approximately

mum and test densities, relative densities, target mois-

6%. In both cases, moisture content was on the dry side

ture contents, and void ratios for the various test sam-

of optimum. Average void ratios of the large-scale and

ples are presented in Table 9. Our target density was

150-mm-diameter samples were 0.143 and 0.220,

the optimum density from T-99. The relative compac-

respectively.

tion of the test specimens ranged between 1.01 and 1.03,

Average resilient moduli from the two tests are pre-

with most around 1.03. The average density of all test

samples was 2179 kg/m3 with a coefficient of variation

sented in Table 10. Individual test results are presented

in Appendix B. Strain measurements at the 21-kPa con-

(COV) of 2.2%. Target moisture contents ranged from

fining pressure and 21-kPa deviator stress were in most

4.0 to 5.1% as shown in Table 9. Void ratios ranged

cases extremely noisy and were not used in the analy-

from 0.180 to 0.268 with an average of 0.220 and a

Table 9. Test sample densities, moisture contents, and void ratios (150-mm-diameter sample).

Target

Optimum

Optimum

moisture

density Test density (kg/m3) Relative density

%

moisture

content (%)

Void ratio

(kg/m3)

crushed

Rep 1

Rep 2

Rep 1

Rep 2

content (%)

Rep 1

Rep 2

Rep 1 Rep 2

100

2030

2090

1.03

4.0

4.6

0.268

75

2129

2178

2153

1.02

1.01

5.1

4.9

5.1

0.217

0.231

50

2118

2174

2153

1.03

1.02

4.7

4.7

4.7

0.219

0.231

25

2100

2157

2170

1.03

1.03

4.9

5.1

4.9

0.267

0.221

0

2187

2245

2232

1.03

1.02

4.6

4.0

4.0

0.180

0.187

0

2187

2243

1.03

4.6

4.0

0.182

13

Previous Page

Previous Page