Table 4. Optimum moisture densities from AASHTO

T-99 and QMOT tests.

From T-99

From QMOT

Moisture

Dry

Moisture

Dry

content

density

content density

(kg/m3)

(kg/m3)

Test material

(%)

(%)

100% Natural

4.2

2180

4.9

2404

75N - 25C

4.9

2129

5.1

2381

50N - 50C

4.8

2117

4.6

2349

25N - 75C

5.1

2091

5.0

2346

100% Crushed

4.6

2028

6.0

2319

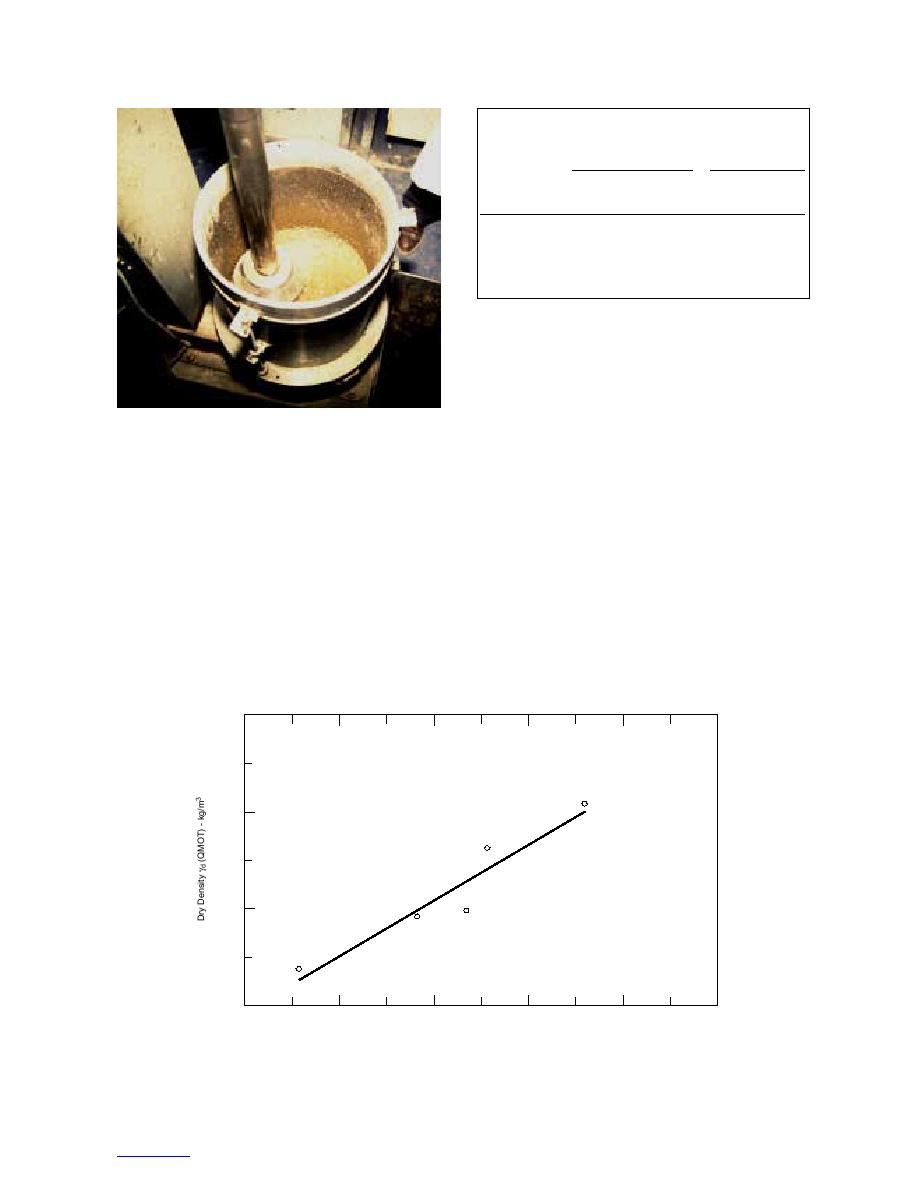

T-99 densities is shown in Figure 8. Based on the test

results, an estimate of the large-scaled density can be

made from the T-99 test results from the following equa-

tion:

γ d = 0.57γd T99 + 1163 (kg / m3 ) (see Fig. 8).

Figure 7. QMOT test equipment for moisture den-

(4)

sity test.

RESILIENT MODULUS AND

In both cases, the 100% crushed aggregates had a

SHEAR STRENGTH

lower density than the 100% natural material and, as

percent of natural aggregates in the mixture increased,

Resilient modulus and shear strength tests were con-

so did the dry density. A comparison of the optimum

ducted at the Corp of Engineers' Engineer Research

moisture and dry density from both tests is presented

and Development Center Geotechnical Structures Lab-

in Table 4. The moisture contents are significantly dif-

oratory (ERDC/GSL) in Vicksburg, Mississippi. The

ferent at the two ends of the spectrum (all natural and

blending of the natural to crushed ratios (100% natural/

all crushed). At the other percentages, they are very

0% crushed, 75% natural/25% crushed, 50% natural/

similar. The density on the average is about 12% higher

50% crushed, 25% natural/75% crushed, and 0% natu-

from the large-scale QMOT tests than from the AASHTO

ral/100% crushed) were done by VAOT personnel and

T-99 tests. The relationship between the large-scale and

shipped in 189-liter drums. Prior to sample fabrication,

2450

2400

2350

γd (large scale) = 0.57(T99) + 1163

R2 = 0.91

2300

2000

2050

2200

2100

2150

2250

Dry Density γd (T99) - kg/m3

Figure 8. Relationship between dry densities from T-99 and QMOT for test aggregates.

6

Previous Page

Previous Page