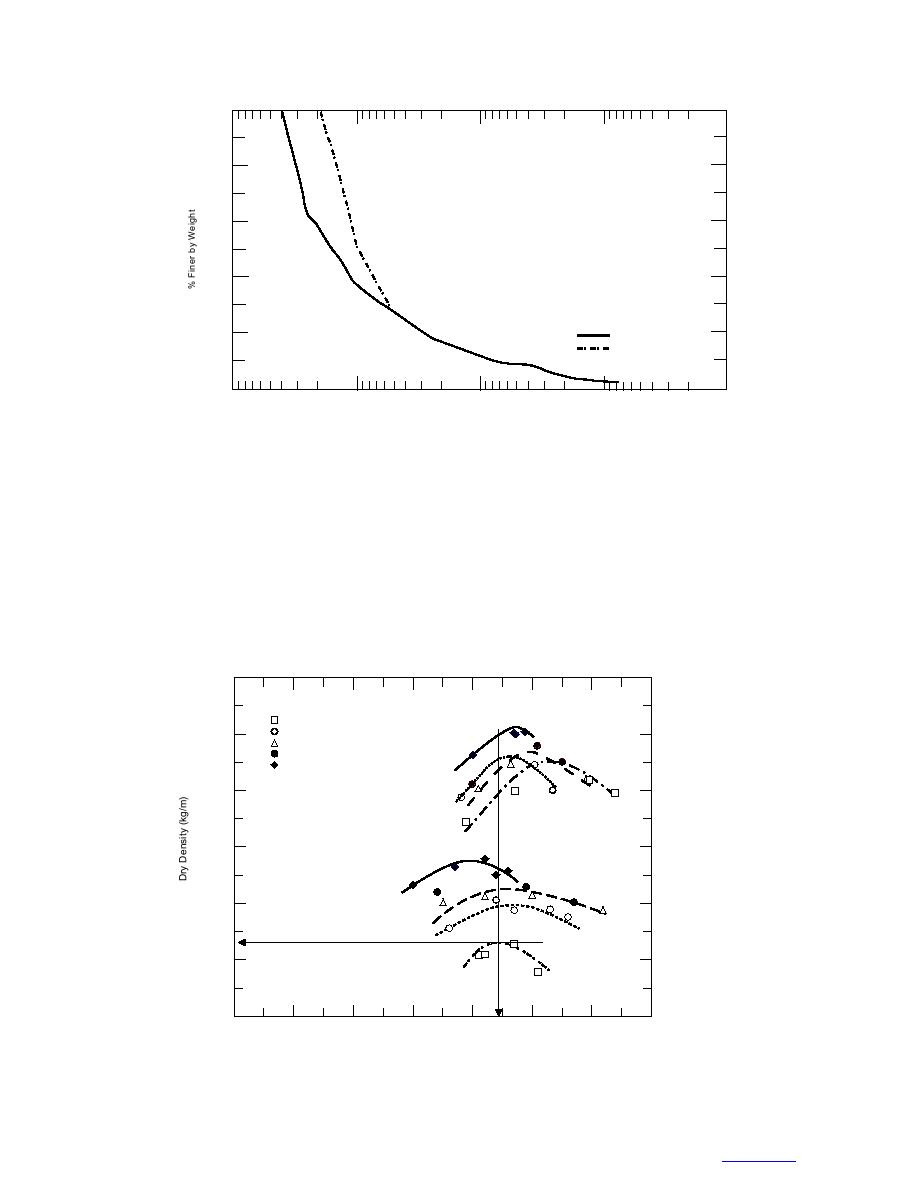

100

80

60

40

20

Original

AASHTO T-99

0

100

10

1

0.1

0.01

Grain Size (mm)

Figure 5. Gradation of subbase aggregate used in the AASHTO T-99 test.

five lifts and each lift was compacted with 56 rammer

procedure was modified to simulate the impact energy

blows. Test results are presented in Figure 6.

from the AASHTO T-99 test. The material was placed

A similar set of moisture density tests was conducted

in three lifts and each lift was compacted with a 15-kg

by CRREL using the test aggregate (Fig. 5) in a larger

rammer at a drop height of 450 mm (Fig. 7). The mold

mold (300-mm diameter) at the Quebec Ministry of

sat on a rotating base and rotated as the layer was com-

Transportation (QMOT) materials research laboratory

pacted. Each layer was tamped 60 times. After the third

in Quebec City (see Fig. 6). The test procedure was

layer, the material was leveled and weighed, collected

initially set up to simulate impact energy similar to that

in a tray, and weighed again. It was then dried in the

from the Modified Proctor Tests. For these tests, the

oven overnight.

2500

100% Crushed

75% Crushed

2400

50% Crushed

25% Crushed

100% Natural

LARGE

2300

SCALE

2200

2100

2000

T99

1900

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Moisture Content (%)

Figure 6. Moisture density curves from T-99 and QMOT tests.

5

Previous Page

Previous Page