The Effect of Aggregate Angularity

on Base Course Performance

VINCENT C. JANOO AND JOHN J. BAYER II

where Mr

=

resilient modulus

INTRODUCTION

θ

=

bulk stress (at maximum deviator stress)

Base course performance in a pavement structure is

q

=

deviator stress

dependent on its properties. In current mechanistic

k1, k2, k3

=

material parameters (regression constants).

design procedures, this performance is tied to the elas-

However, gradation, plasticity index, density, tem-

tic properties of resilient modulus and Poisson's ratio.

perature, and moisture content also have an effect on

Resilient modulus is affected by stress state, moisture

the resilient modulus of base course materials. With

content, temperature, plasticity index, density, and gra-

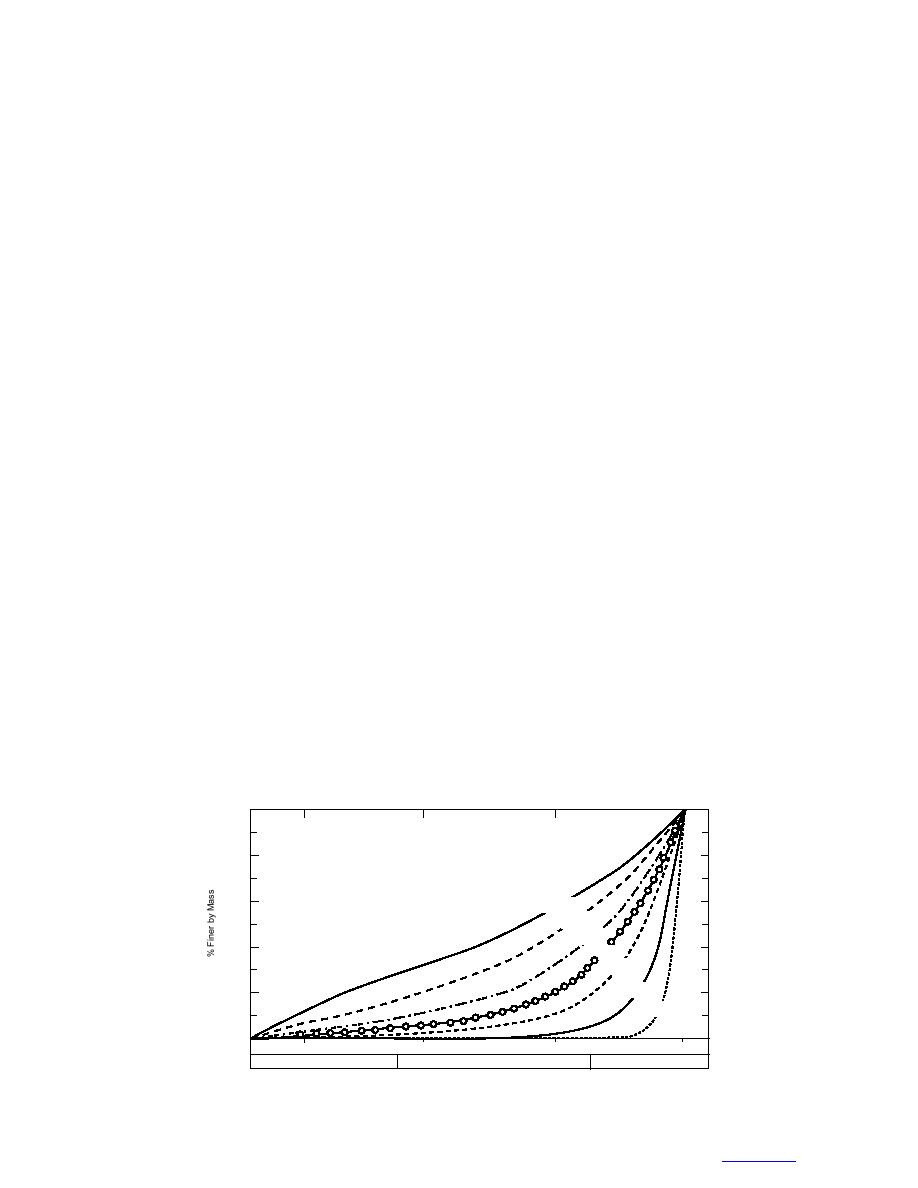

respect to gradation, several factors affect the resilient

dation. Details on the effects of the various factors can

modulus: fine content, gradation curve shape, and max-

be found in state-of-the-art reports by Kolisoja (1997)

imum aggregate size (Thom 1988). For example, re-

and Lekarp (1999). The effect of stress state has been

ferring to Figure 1, the stiffness of dry crushed lime-

researched in depth and the resilient modulus of granu-

stone increased by 1.5 to 1.8 when the sand content

lar materials has been related to bulk and deviator (or

(indexed by the value n) increased from n = 0.25 to n =

octahedral) stresses (Brown and Pell 1967, Hicks and

5.0. Sand content increases with decreasing values of

Monismith 1972, Uzan 1985). The following can be

n. Figure 1 can also be used to infer the effect of max-

used to estimate resilient modulus as a function of stress

imum size on resilient modulus. It can be surmised from

state:

Figure 1 that if resilient modulus increases with de-

M r = k1θk2

creasing values of n, then resilient modulus decreases

with increasing aggregate maximum size. Similar re-

Mr = k1θk2 q k3

(1)

sults were reported by Kolisoja (1997).

100

Characteristic Equation

% Finer = 100 (d/d100)n

80

Where: d

= sieve size

d100 = max particle size

60

n=0.25

n=0.35

n=0.5

40

n=0.7

n=1.0

n=2.0

20

n=5.0

0

0.1 mm

1 mm

10 mm

0.01mm

Silt

Sand

Gravel

Figure 1. Grain size distribution. (After Thom 1988.)

Previous Page

Previous Page