specific ice types and conditions, and general trends

are well known. Our CFG ice was very fine-grained,

equiaxed, isotropic material. The ice was free of

particulates and because the snow from which it was

made was collected from an undisturbed area, we

assume that it had no substantial chemical

Data obtained for all samples tested are given in

Appendix B.

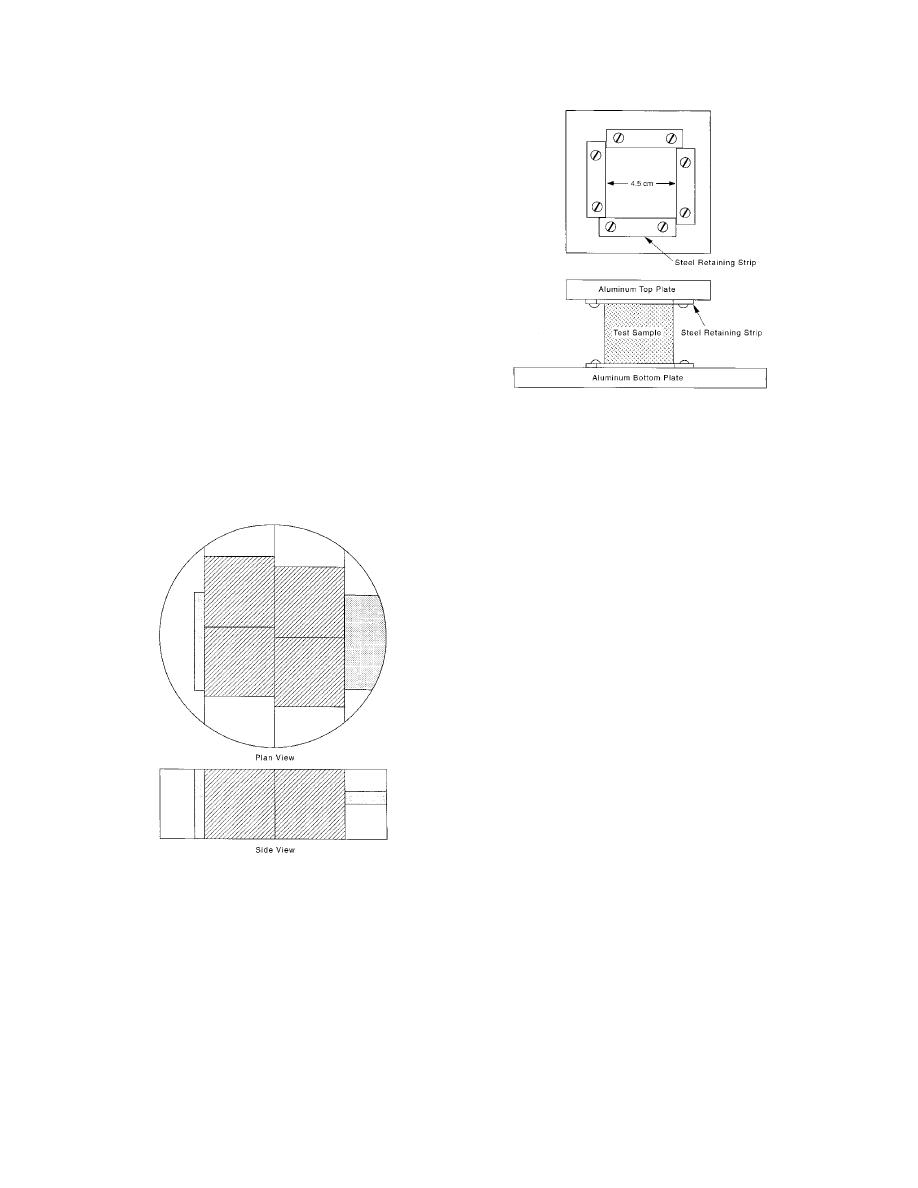

Samples and apparatus

Because the minimum thickness of our bricks was

4.6 cm, we used cubic samples 4.5 cm on a side as our

sample configuration. Four such cubes were cut from

each of two bricks for each set of conditions, resulting

in eight samples for each sample series. The cutting

pattern from each brick is shown in Figure 2.

Figure 3. Platens used for compressive

We also collected bubbly ice from a local pond and

strength tests in this study.

clear ice from Lake Superior to test in parallel with

at about 10C for a few days before they were cut

our brick samples. The pond ice used was taken from

a depth of about 15 cm beneath the ice surface as well

and tested.

as another sample from a depth of about 50 cm. The

The samples were cut using a bandsaw and the cut

faces were ground using sanding screen. The upper

surface was marked with photocopier toner and the test

samples were then returned to their storage temperature

for a day before testing. The 1-day samples were

prepared as soon as they were compacted and stored

for one day in their test configuration. All samples were

tested upside up.

A drawing of the platens we used is shown in Figure

3. The end plates were made of 1/2-in.-thick aluminum,

using the supplied factory finish. They were not

polished or ground. Steel strips about 3 mm thick were

attached to the plates as shown to ensure that the sample

was centered under the head of the press and that the

top plate did not move. The top plate was not attached

to the head, and fitted loosely over the top of the

sample, to minimize stress concentrations caused by

any deviation from parallel of the top and bottom of

the sample. Plastic sheeting was placed between the

sample and both top and bottom platens.

We used an Instron Universal Testing Instrument

(Instron Engineering Corporation) Model TTC

Figure 2. Cutting pattern used in prepar-

overhead press with a rated load of about 10,000

ing samples for use in uniaxial compres-

pounds (about 5000 kg) for the uniaxial unconfined

sive strength testing (hatched areas) and

for crystallographic studies (shaded

compressive tests. The press speed measured without

areas).

load was 0.08 cm/sec. We used a Sensotec Model 41/

572-05 load cell with a range of 05000 pounds (about

15-cm ice was very bubbly and discolored snow ice.

2500 kg). The linear motion transducer was a Lin-R-

The 50-cm ice was less bubbly and discolored and had

Tron Model LRT-S-050B with a range of 02 in. (05

cm) and resolution of 100. The load cell and the

a density of 880 kg/m3. The ice from Lake Superior

was taken from a slab that had washed up onto the

motion transducer readings were recorded in computer

shore. It was very clear and clean and had a density of

files, giving us time (in increments of 0.43 s), load (in

920. All of these samples were stored in the coldroom

pounds) and displacement (in inches). These data were

4

Previous Page

Previous Page