900

by cutting a cylinder out of the ice using a bandsaw

and further cutting it into sample disks as described

760

above. These were stored in the coldroom at about

10C for a day before testing.

Ice

820

We used the CRREL snow load frame for the

Snow

flexural strength tests. This was equipped with an

780

Interface, Inc., 250-pound load cell and Schaevitz

MagneRule displacement transducer. The cylindrical

0 seconds

740

30 seconds

indenter, attached to the load cell, was 1 cm in diameter

60 seconds

with a flat tip. It was centered over a short section of

700

iron pipe with an outside diameter of 6 in. (15 cm) and

3.5

5.5

6.5

7.0

4.0

4.5

5.0

6.0

Compaction Pressure (MPa)

a 0.5-in. (1.25-cm) wall thickness, so that the brick

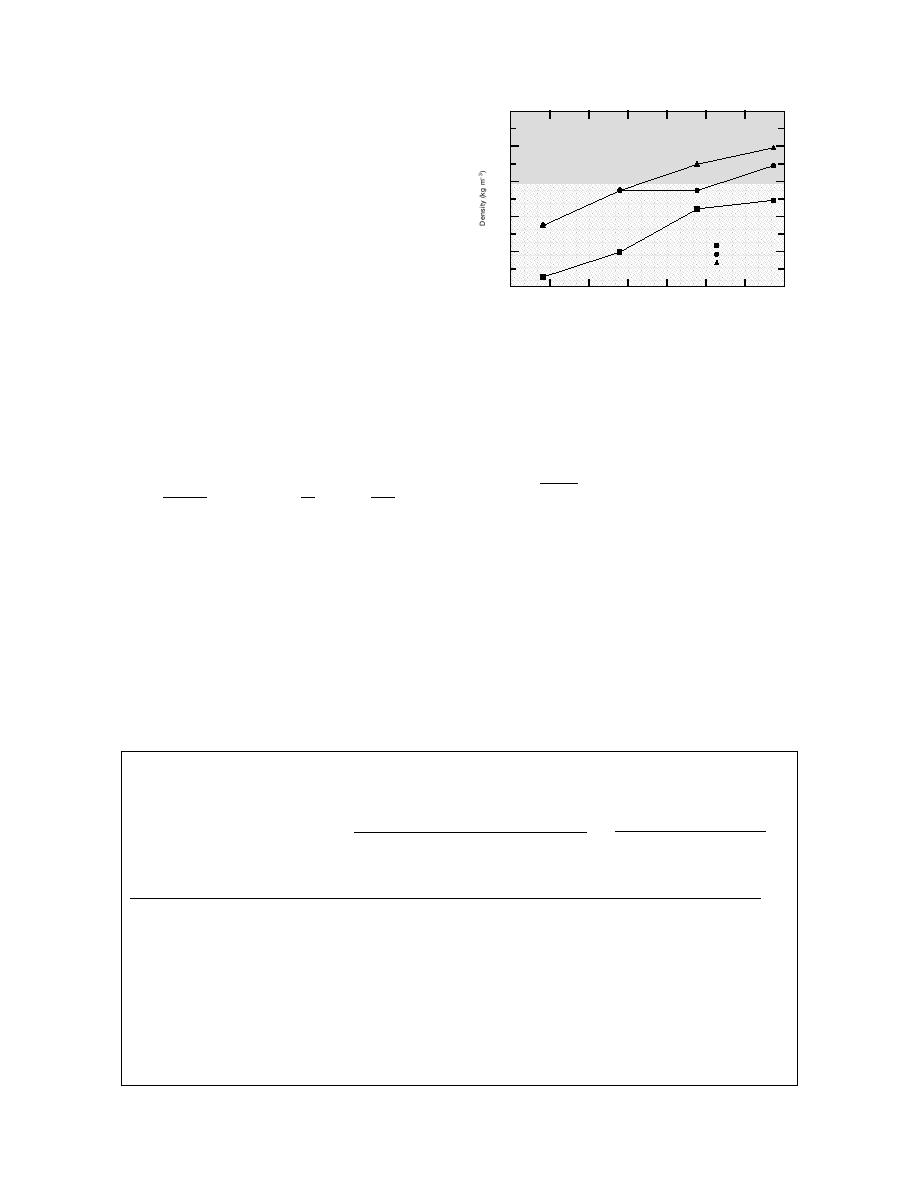

Figure 9. Density in kg/m3 of snow compacted at

samples fit across the opening without overhang. The

different pressures. The different data series rep-

press speed, without load, was 0.06 cm/sec. The

resent samples that were held at the final pressure

apparatus is shown in Figure 8.

for 0, 30, and 60 seconds.

The flexural strength of the plates was calculated

Our supporting ring had an inside diameter of 12.65

using the method described by Yakovlev (1971) and

cm, giving r = 6.33, and our indenter was a 1-cm cylin-

Lavrov (1969). The equation yields the maximum

der, giving r0= 0.5. Substituting these values, eq 3

normal stress in a freely supported plate of constant

becomes

thickness with a centrally located circular load:

2.09P

.

(4)

σf = -

r02

(

)

(

)

3P

r

σf = -

m + m + 1 ln - m - 1

(3)

h2

2πmh2

4r 2

r0

Results

Table 3 gives the average flexural strength for each

σf = flexural strength (kg/cm2), later

of the sample series. The strength was calculated using

where

converted to MPa

eq 4, and this value was then multipied by 0.65, the

P = maximum load (kg)

empirical coefficient determined by Lavrov to

m = inverse of Poisson's ratio

normalize the round plate tests with respect to beam

h = plate thickness (cm)

bending tests. The strength values have been converted

to MPa.

r = the inside radius of the supporting ring

Table 4 gives the flexural strength determined for

(cm)

various types of ice using beam bending and round plate

r0 = the radius (cm) of the load (indenter).

methods. The round plate data have been normalized

as above. The strengths calculated for the three series

Assuming a Poisson's ratio of 0.33, m becomes 3.

Table 4. Comparison of the flexural strength of ice under different conditions. Test conditions and ice

type are given, where known.

Beams

Disks

Test

Measured

Test

Measured

Adjusted

temperature

flexural

temperature

flexural

flexural

(C)

(C)

strength

strength

strength

Type of ice

(MPa)

(MPa)

(MPa)

Sea ice (3 ‰) (Lavrov 1969)

1

0.75537

1

1.10853

0.721035

Sea ice (0.5 ‰) (Lavrov 1969)

2.5

0.981

2.5

1.55979

1.014354

Artificial ice (Lavrov 1969)

5

1.372.74

4

2.3544

1.4715

Lake ice (S2) (Lavrov 1969)

0.5

0.882.26

Lake ice (S2) (this study)

10

2.0601

1.3734

Lake ice (Gow 1977)

0

0.231.52

Freshwater (Schwarz and Weeks 1977)

1.03

Snow ice (T1) (Stearns 1964)

15

2.3544

Snow ice (T1) (this study)

10

3.1392

2.0601

Unknown (Gold 1977)

3.534.51

2.262.94

CFG ice (this study)

10

4.024.91

2.553.14

8

Previous Page

Previous Page