Table 3. Adjusted flexural strength (MPa) of CFG ice and

natural ice used in this study.

Storage temperature (C)

Test series

10

15

25

2.71 0.50

2.65 0.26

2.59 0.37

1 day

3.04 0.36

2.59 1.23

3.11 0.53

5 days

2.61 0.36

2.70 0.28

10 days

--

2.86 0.28

3.17 0.34

2.71 0.45

20 days

2.04 0.60

Pond ice

1.34 0.23

Lake ice

for all CFG ice samples against their temperature and

trend was more pronounced at the lower strain rates

(106/sec). Figure 6 shows the relationship between

duration conditions. There is no convincing evidence

of time or temperature dependence over the range we

the unconfined compressive strength of ice and its grain

size taken from a number of studies. The data from

used. This confirms our expectation that sintering was

our brick material fall in the predicted area of the plot,

complete at the time of compaction.

although data from the pond and lake ice appear weaker

Schulson and Cannon (1984) ran a series of uniaxial

than expected.

compressive tests on polycrystalline ice with grain sizes

ranging from 1 to 10 mm. They found a clear trend of

Flexural testing

increasing peak stress with decreasing grain size. In

tests with high strain rates (103/sec) this trend was

Because the bricks we made were not large enough

especially pronounced. They also found a much higher

to conduct standard bending tests using beams, we used

peak stress with decreased grain size. In this case the

round plates (disks), a technique that is less well known,

but for which data for comparison do exist in the

literature. Lavrov (1969) describes a study in which

both beam bending and round plate tests were done

for ice collected during an Arctic cruise. The beam-

bending strength was about 65% of that measured using

round plates. That is,

σb

= 0.65

(2)

f

σd

f

σ d = beam-bending flexural strength

where

f

σf

b = disk-bending flexural strength.

A later study in the laboratory using laboratory-

prepared and natural freshwater ice yielded the same

relationship.

Data obtained for all samples tested are given in

Appendix C.

Samples and apparatus

Flexural tests were made using disks cut from CFG

ice cylinders produced by compaction. We used a

handsaw and mitering jig, shown in Figure 7, to make

disks about 1.5 cm thick for the flexural strength tests.

We then planed the cut surfaces using sanding screen,

and returned the disks to their assigned storage

temperatures for a day along with the compressive test

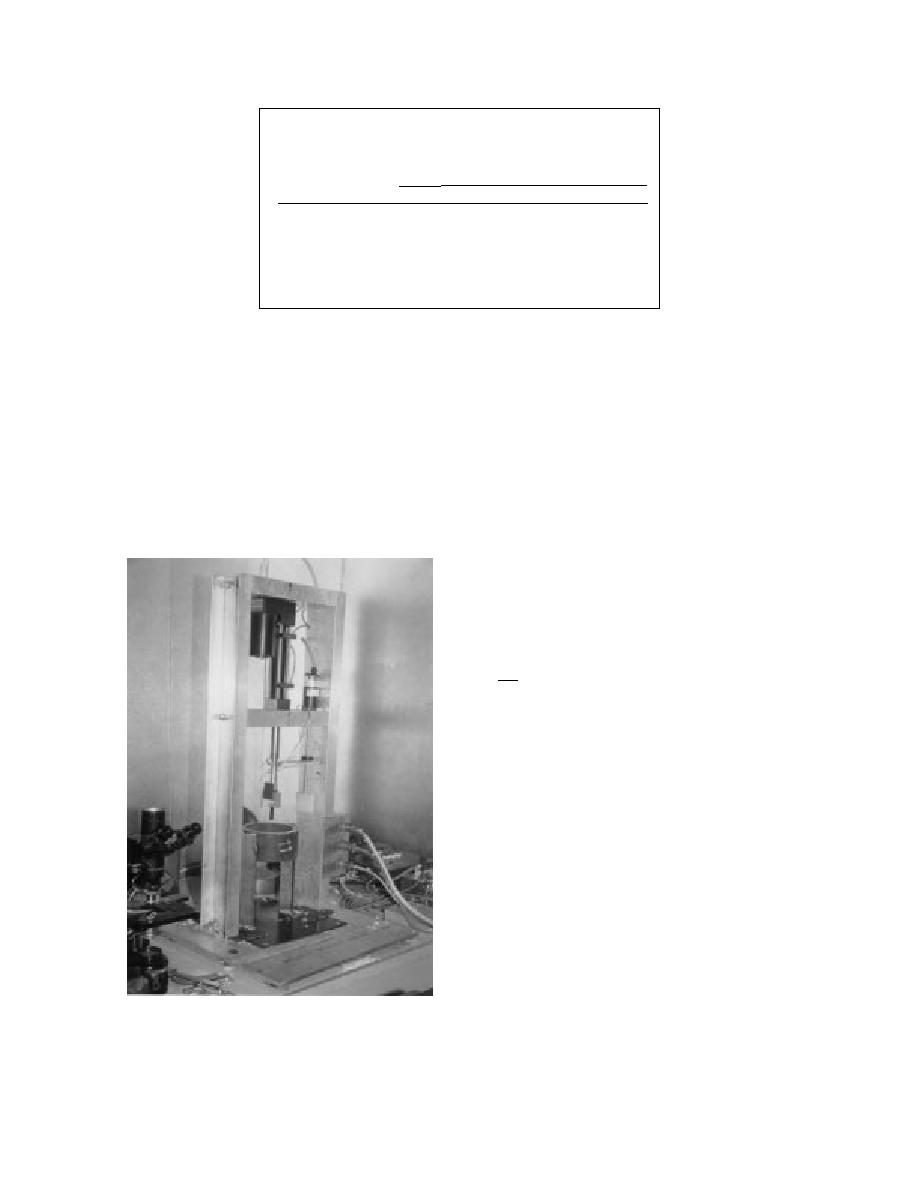

Figure 8. CRREL snow load frame used for

samples. Two samples were obtained from each brick.

flexural strength testing. The sample disk

We obtained eight samples for each test series.

was placed across the metal cylinder cen-

tered beneath the indenter.

Sample disks were also made from the natural ice

7

Previous Page

Previous Page