series of bricks using final pressures ranging from 3.92

to 6.87 MPa, and held the target pressure 0, 30, or 60

seconds. The load cell was placed between the

hydraulic head and the sample to measure the load as

it was applied, and to maintain the target pressure. The

results of this trial series are shown in Figure 9. There

is a clear trend toward greater density with greater

pressure and greater time held. The density region

above 820 kg/m3, at which compacted snow is said to

become ice, is shaded in Figure 9.

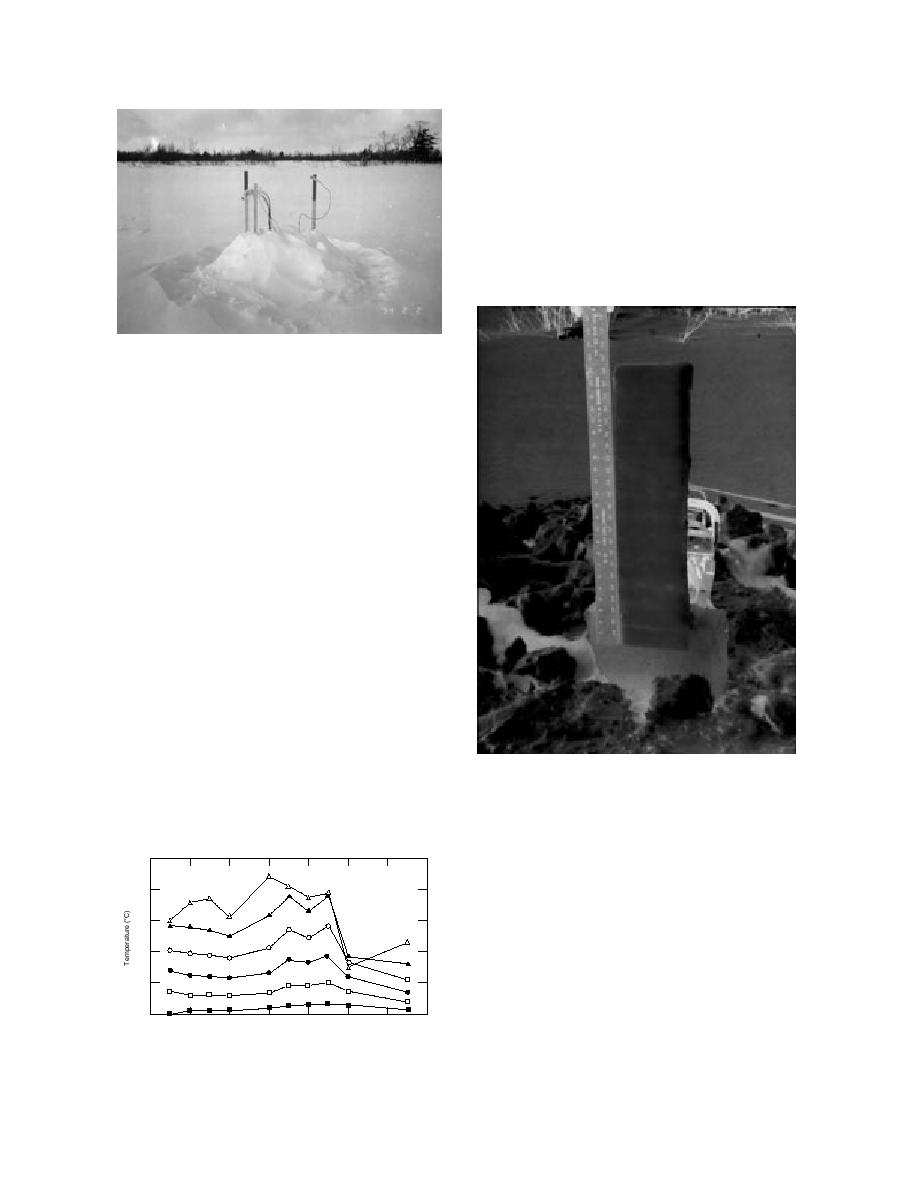

Figure 10. Snow mound enclosing the stack of 12

sample bricks used to study the effect of a thermal

gradient on CFG ice. The cluster of wires on the

left lead to the 12 thermocouples embedded in the

stack. The single lead on the right leads to a ther-

mistor probe installed about 10 cm from the stack.

Plastic bags cover the connectors for all of these

leads.

of tests in which Lavrov used both beams and plates

show very good agreement between the adjusted plate

data and the beam data.

The data we obtained using S2 ice collected from

Lake Superior show good agreement with other

determinations of this ice type, as did the snow ice (T1)

results. The flexural strength measured for CFG ice

was considerably greater than that for both the natural

ice measured in this study as well as for all the other

ice types except the series mentioned by Gold (1977).

Since no details are available regarding the ice type or

test temperature, we have no explanation for his obser-

vations.

Effect of final compaction pressures

Figure 12. Cut face of the stack of sample bricks at

and duration of final load

the end of the test. The bottommost brick is em-

To establish whether a compaction pressure as

bedded in snow ice because of flooding of the ice

great as 6.87 MPa was necessary to produce CFG ice,

early in the test period. The measuring stick is

and how long the pressure should be held, we made a

marked in inches.

25

Effect of thermal gradient

50 cm

20

Many potentially valuable applications for these

building blocks involve using the material in a thermal

40

15

gradient. Pavements over wet areas and walls of

30

equipment shelters are two examples. Since compacted

10

20

snow used in such conditions would quickly lose its

10

strength and integrity through recrystallization, we

5

Ice Surface

tested the response of CFG ice to these conditions.

0

Twelve bricks were placed in a stack on the ice cover

1 Feb '94

3

5

7

9

11

13

15

of a pond. The snow cover was cleared off so that the

Figure 11. Temperature profile showing the tem-

bottommost brick was in contact with the ice. A

perature variation over two weeks at six levels

thermocouple was placed beneath the center of the

in the stack of sample bricks.

9

Previous Page

Previous Page