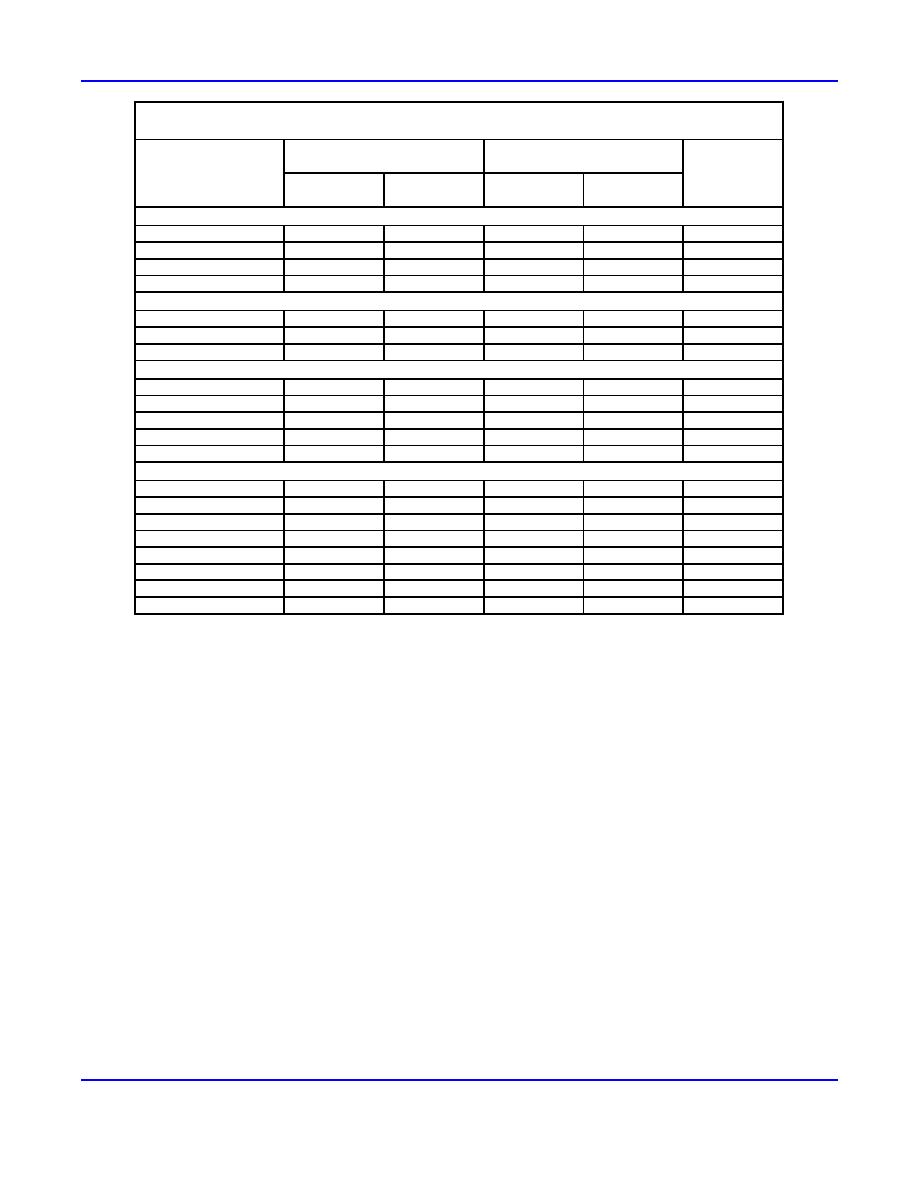

Table 2. Before- and after-exposure ice adhesion stress values, in kPa, for materials and coatings.

Percentage changes in boldface type were statistically significant at the 95% confidence interval.

Pre-Exposure Shear Stress

Post-Exposure Shear Stress

(kPa)

(kPa)

Change in

Mean Value

Standard

Standard

Material

(%)

Mean

Deviation

Mean

Deviation

Thermoplastics

Acetal

544.6

147.5

355.7

94.8

35

Delrin

864.3

213.4

508.5

334.9

41

Teflon

237.8

103.0

230.2

343.5

3

UHMWPE

294.8

120.7

179.9

65.4

39

Off-the-Shelf-Coatings

PSX-700

659.3

48.0

977.7

52.8

48

Inerta

851.8

500.3

563.2

191.3

56

Envelon

1279.0

403.0

983.8

72.5

23

Standard USACE Lock Coatings

MIL-P-24441

1361.8

260.7

1408.3

327.4

3

V-102e

1119.7

180.7

1373.7

290.2

23

V-766e

1164.5

348.9

957.3

163.9

18

V-103c

536.0

237.9

725.1

233.2

35

C-200a

1250.6

396.8

1317.3

414.6

5

Standard Lock + Off-the-Shelf Coatings

V-103c + PSX-700

765.8

139.5

959.7

46.2

25

V-103c + TroyGuard

795.9

168.5

643.3

170.4

19

V-103c + Wearlon

1162.7

418.3

1219.2

155.9

5

V-103c + Kiss-Cote

497.9

143.7

657.6

69.7

32

C-200a + Kiss-Cote

1196.3

110.5

1503.7

200.3

26

C-200a + Wearlon

984.7

145.7

1124.1

152.6

14

C-200a + PSX-700

729.6

60.8

729.2

139.2

0

C-200a + TroyGuard

732.6

188.3

670.4

125.9

8

Notably, two of the thermoplastics, Acetal and Delrin, even had significantly lower after-exposure ice adhesion values.

Four of the coating combinations, however, had statistically significantly higher after-exposure values. Both the C-200a and

V-103c Corps paints having Kiss-Cote applied over them yielded higher average adhesion values, indicating that the clear,

liquid (invisible, after it dries) Kiss-Cote material had eroded away during the six-month exposure period. This conclusion is

consistent with the measured adhesion strengths for both of these samples after they were weathered; each sample had

adhesion values in the same range as the comparable uncoated and weathered Corps paint samples. This indicates that even

though Kiss-Cote is effective at reducing the adhesion strength of ice when newly applied, it may require annual, or more

frequent reapplication.

The PSX-700 epoxy coating both by itself and over the V-103c Corps paint yielded higher after-exposure adhesion

values. However, the PSX-700 coating did not bond well to the underlying V-103c. One of these six replicates was damaged

when portions of the coating peeled during the before-exposure adhesion testing, and most of the "PSX-700 over V-103c"

samples returned from the field with flaking in the outer coating, revealing the Corps paint beneath. This particular system's

durability, both in the laboratory and field testing, was limited as a result of poor bonding between the outer PSX-700 and the

V-103c undercoat. The PSX-700 by itself appeared to withstand the field trial very well (its general condition was excellent)

even though its ice adhesion values increased.

Conclusions

Icephobic materials do not prevent ice formation on exposed structures. Instead, they lower the adhesion strength of ice

and therefore may be considered as enhancements to other ice removal methods, such as mechanical, steam, electro-thermal,

or electro-mechanical. Laboratory and field-exposure results provide information that can assist in evaluating the relative

performance of materials and coating systems. "Performance" of the coating systems was measured in terms of durability and

the strength with which ice adheres to each system before and after field exposure.

6

ERDC/CRREL TN-03-4

Previous Page

Previous Page