Ice Engineering

U.S. Army Engineer Research and Development Center, Hanover, New Hampshire

Progress in Evaluating Surface Coatings

for Icing Control at Corps Hydraulic Structures

Removal of accreted ice during the winter at Corps hydropower and navigation projects is time-consuming, costly, and

sometimes hazardous. Annual maintenance costs incurred at Corps of Engineers projects as a result of ice problems were

estimated by Haynes et al. (1993) to be million in 1992 (Fig. 1). A previous issue of Ice Engineering (Haehnel 2002)

described an ongoing icing research program at the Cold Regions Research and Engineering Laboratory (CRREL), part of the

Corps' Engineer Research and Development Center (ERDC). Program tasks included an assessment of thermoplastics and

spray-on coatings for reducing the cost of icing control at Corps projects. The goal of the research effort is to determine

whether commercially available surface coatings and thermoplastic cladding materials can make icing control more econom-

ical. In this issue, we will discuss further progress made in this program in the form of laboratory and field tests.

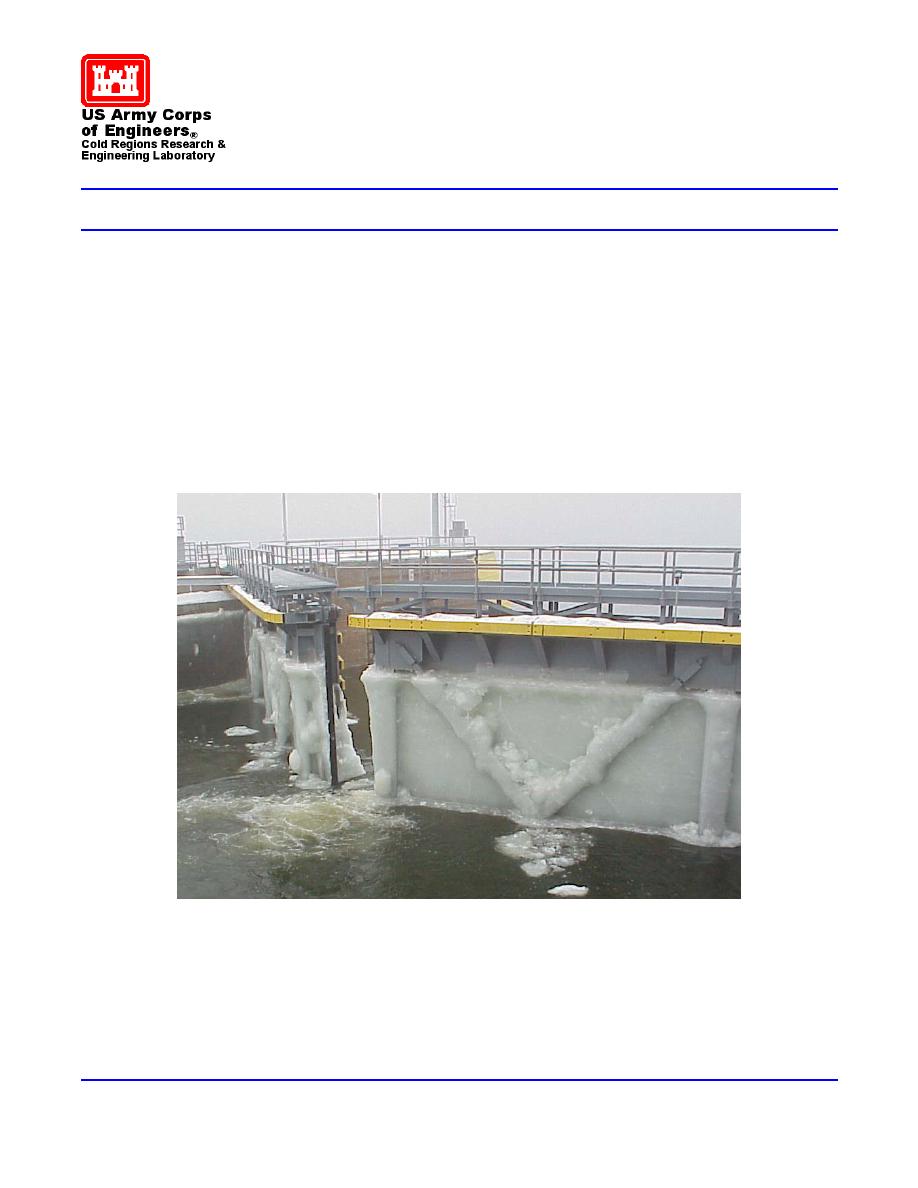

Figure 1. Ice buildup on miter gate at a Mississippi River navigation lock.

Numerous materials, coatings, and paints having low friction properties are commercially available. Many are even

marketed as "icephobic," the name implying that ice accretion is reduced or eliminated. Our research has shown that these

materials will not prevent ice buildup. In fact, ice often builds on these materials at the same rate as on any other material.

Instead, they typically reduce the force or energy required to remove it (i.e., the bond strength of the ice to the icephobic

material is lower). For this reason, icephobics are sometimes used in conjunction with other ice removal techniques, such as

heating, electro- or pneumatic expulsion, or--more often than not--baseball bats and pike poles.

ERDC/CRREL Technical Note 03-4

October 2003

Previous Page

Previous Page