Table 4. Admixtures that will produce strength at

low temperature, but it recovers full strength

10C at least as fast as normal concrete cured at 5C.

once warm weather returns. Thus, antifreeze

admixtures are sort of an insurance policy against

Dosage

Water to

unexpected freezing.

by wgt of cement

cement ratio

Admixture

Chemicals

(%)

(w/c)

The above discussion assumes that concrete

cast during cold weather must attain significant

1

Sodium nitrite

6.0

0.45

early or full late-age strength, or both, to be ser-

Potassium carbonate

0.06

viceable. However, attaining full strength may

2

Sodium nitrite

6.0

0.48

not be necessary. If less late-age strength can be

Sodium sulfate

2.0

tolerated, at least to the degree that now happens

3

Sodium nitrite

6.0

0.45

with concrete cast during hot weather, many of

Calcium nitrite

2.0

our everyday chemicals become potential anti-

4

Sodium nitrite

9.0

0.45

freeze admixtures. Chemicals such as automobile

antifreeze, alcohol, deicing salt, and common

even available. For short-term needs,

fertilizer can play an important role in protecting

there is another way to approach win-

ter concreting. This report shows that

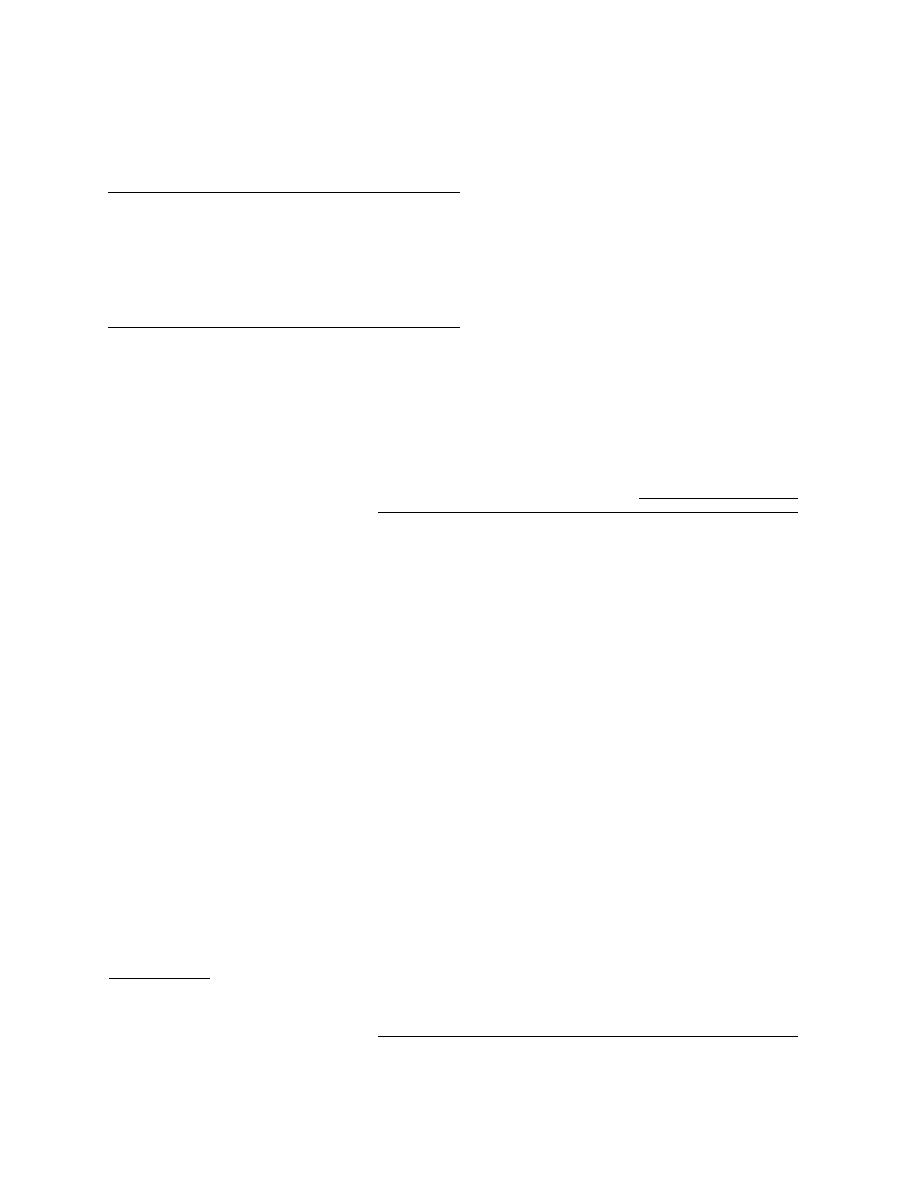

Table 5. Everyday chemicals that allow concrete to gain at least

simply adding chemicals to the mix

75%* strength after being at low temperature for 28 days followed

water will make the resulting mortar

by room temperature for 28 days.

(concrete) resistant to freezing. These

Dosage

chemicals, called antifreeze admix-

by weight of

Strength (%) relative to mortar

cured 28 days at 20C

tures, serve to depress the freezing

cement

5C

10C

20C

w/c

(%)

point of water and to accelerate the

hydration rate of cement. Their effec-

Deicers

tiveness depends on temperature,

Calcium chloride

0.41

3

121.3

94.9

80.0

6

133.2

130.2

110.3

amount of chemical, and on how soon

9

108.3

100.2

110.5

the structure is needed.

Potassium acetate

0.41

4

76.0

77.5

78.0

In the situation where the tempera-

6

115.4

78.6

--

ture falls below freezing but the work

8

109.9

90.9

--

Calcium magnesium

0.41

4

87.7

--

--

must still get done in a hurry, there

acetate

6

96.2

--

--

are chemicals that will work very

8

97.9

75.8

96.4

well. Table 4 shows four admixtures

Water softener

that force mortars with internal tem-

Potassium Chloride

0.41

6

77.4

--

--

peratures of 10C* to gain strengths

9

85.3

79.5

--

as if they were cured above 5C.

Fertilizers

Calcium nitrate

3

98.1

88.1

76.8

Moreover, they gain more strength in

0.41

6

92.2

98.8

84.3

the long run than control mortar

9

105.5

99.6

na

cured at 20C (App. A). Thus, these

Potash

0.41

6

90.8

--

--

chemicals make cold concrete behave

9

86.6

78.9

--

Sodium nitrate

0.41

6

109.4

--

--

as if it were warm.

9

108.8

103.1

--

What happens to concrete if, soon

Car antifreezes

after it is placed, its temperature dips

below 10C? All is not lost. Appen-

Ethylene glycol

0.38

3

87.6

80.2

--

0.35

6

119.1

103.6

101.0

dix A shows that concrete made with

0.32

9

95.8

93.0

88.6

the Table 4 chemicals can avoid all

Propylene glycol

0.38

3

90.8

83.8

81.9

0.35

6

86.2

--

--

frost damage, even when cooled to

20C for a long time. The concrete

0.32

9

88.1

80.5

--

Alcohols

may not gain much strength at this

Methyl (wood)

0.38

3

75.7

--

--

0.35

6

96.9

88.4

--

* It is important to know that this is a concrete

0.32

9

79.3

83.7

--

temperature. Because of thermal inertia and

Ethyl (grain)

0.37

4.1

83.6

--

--

heat generated by cement hydration, air tem-

Iso-propyl

0.35

6

90.0

--

--

peratures can be much lower--further study is

needed to define how low. However, until addi-

* The 75% requirement reflects what happens to concrete strength when it is

cured at 50C. In the table, blank spaces indicate that the chemical did not pro-

tional information becomes available, the

duce enough strength; na means that tests were not conducted at that condition.

10C should be considered air temperature.

7

Previous Page

Previous Page