low temperatures. As seen, there is a scattering of

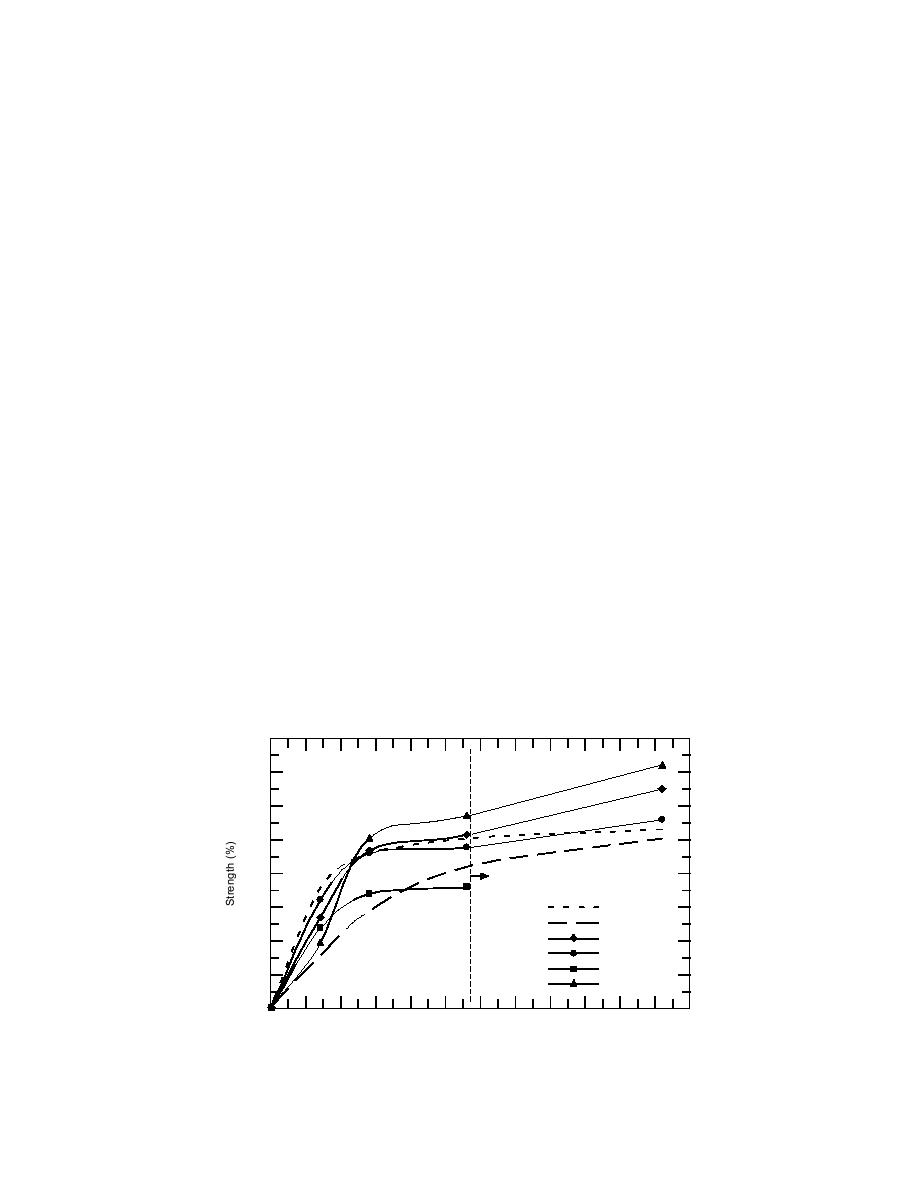

strengths developed by antifreeze mortars cured

the data points about the least-squares regression

at low temperature to those developed by normal

line drawn through them. This scattering is prob-

mortar cured according to current guidelines. In

ably caused by variations in attractive forces

practice, fresh mortar must be kept at or above

5C to ensure against freezing and assure a rea-

between particles and in solubility from chemical

to chemical. The least-squares line reveals that

sonably rapid strength gain. Therefore, the

each mole (mol) of solute reduces the freezing

strength-gain curve for control mortar cured at

point (FP) of the water by 1.76C. Further, it

5C is shown in Figure 2 as the benchmark for the

shows that admixture-free mortar should freeze

antifreeze mortars in this study. The curve for

at 1.28C. (The measured freezing point of the

20C mortar is shown for comparison. Any

control mortar was 1.3C.)

admixture that caused mortar, cured below 0C,

to gain strength at least as rapidly as control mor-

tar cured at 5C was deemed acceptable.

FP = 1.76 mol 1.28 .

(1)

Figure 2 shows four mortars that produced at

least benchmark strengths at 10C. Quite a few

Interestingly, the relationship between molali-

ty and freezing point remains quite good, even at

of the chemicals produced excellent results at

5C, while none passed the test at 20C. The

the highest dosage. Thus, eq 1 is a good first esti-

mate of expected freezing point whenever the

best single chemical was sodium nitrite. At a dose

chemical composition of the admixture is known.

of 9% by weight of cement, this chemical pro-

duced strengths at 10C that not only exceeded

However, it is always best to experimentally

determine the freezing point because, as noted,

the benchmark, they nearly equaled the strengths

of control mortar cured at 20C between 14 and 28

the colligative behavior of chemicals can vary

from that predicted by eq 1.

days. Thereafter, the sodium nitrite outper-

formed the 20C control mortar. This immediately

suggested that sodium nitrite, which is classified

The basic antifreeze admixture utilizes both

as a freezing point depressant in Table A2, could

accelerators and freezing point depressants.

be improved further by combining it with an

Other chemicals, such as plasticizers, retarders,

accelerator--something from Table A1.

and air entrainers, can be used, but this study did

Two accelerators provided that improvement.

not evaluate them. My objective was to find

Potassium carbonate and calcium nitrite each

affected sodium nitrite's performance at 10C

chemical combinations that promote "adequate"

strength gain while the internal temperature of

differently. (Calcium chloride was tested in the

the mortar was below 0C.

form of a commercial deicer along with sodium

One way to judge adequacy is to compare the

nitrate as a fertilizer. They did not perform as

160

140

120

100

80

20 Cure

Control 20C

60

Control 5C

SN

40

SN/PC

SN/SS

20

SN/CN

0

5

10

15

20

25

30

35

40

45

50

55

60

0

Time (days)

Figure 2. Best strengths at 10C.

5

Previous Page

Previous Page