the control mortar at 50C. Except for calcium

nitrite were the most active chemicals studied.

They produced 7-day strengths at 10C that

chloride and calcium bromide, the amount of

strength increase depended on the amount of

were comparable to control mortar cured between

5 and 10C. Since accelerators are only one com-

chemical added to the mortar. The calcium chlo-

ride and calcium bromide produced approxi-

ponent of an antifreeze admixture, these results

mately the same 7-day strengths despite differ-

are remarkable. Interestingly, too, the lowest

ences in doses.

measured freezing points of the mix waters were

6.2 and 5.7C for the calcium chloride and calci-

The best known cement hydration accelerator

is calcium chloride. As Table 2 shows, it provides

um nitrite, respectively. These are not insignifi-

more strength gain at a given dosage than the

cant from practical considerations as the control

mortar froze at 1.3C.

other accelerators. It is also the cheapest of all the

chemicals tested in this study. However, a major

drawback of calcium chloride is its tendency to

Freezing point depressants

corrode metal. As a result, calcium chloride is not

The second and final function of an antifreeze

recommended by current standards beyond 2%

admixture is to depress the freezing point of

by weight of cement in reinforced concrete and is

water. This function depends on a colligative

not recommended at all in pre-stressed concrete.

property called molality--the number of parti-

But, for expedient purposes where long-term

cles (moles) that dissolve into 1 kg of water. This

effects are less important or for non-reinforced

is a group of chemicals that are generally weak

structures where corrosion is not an issue, higher

accelerators or retarders, and includes both elec-

dosages are acceptable. Up to 4% was included in

trolytes and nonelectrolytes. Electrolytes are ma-

this study. For practical purposes, the amount of

terials that dissociate into more than 1 mole of

accelerator that can be added to concrete is limited

ions per formula weight, whereas nonelectrolytes

by how early the concrete stiffens before interfer-

remain in molecular form. Examples of electro-

ing with placing, consolidating, and finishing

lytes are sodium chloride and sodium acetate and

operations. Since ready-mix concrete is often pro-

of nonelectrolytes are alcohols and glycols. They

duced at temperatures around 20C during the

work on the principle that solute particles lower

winter, the accelerating potential of chemicals

the vapor pressure and, thus, the freezing point of

was judged at this temperature. Based on this

water.

study, the optimum dosage of accelerators

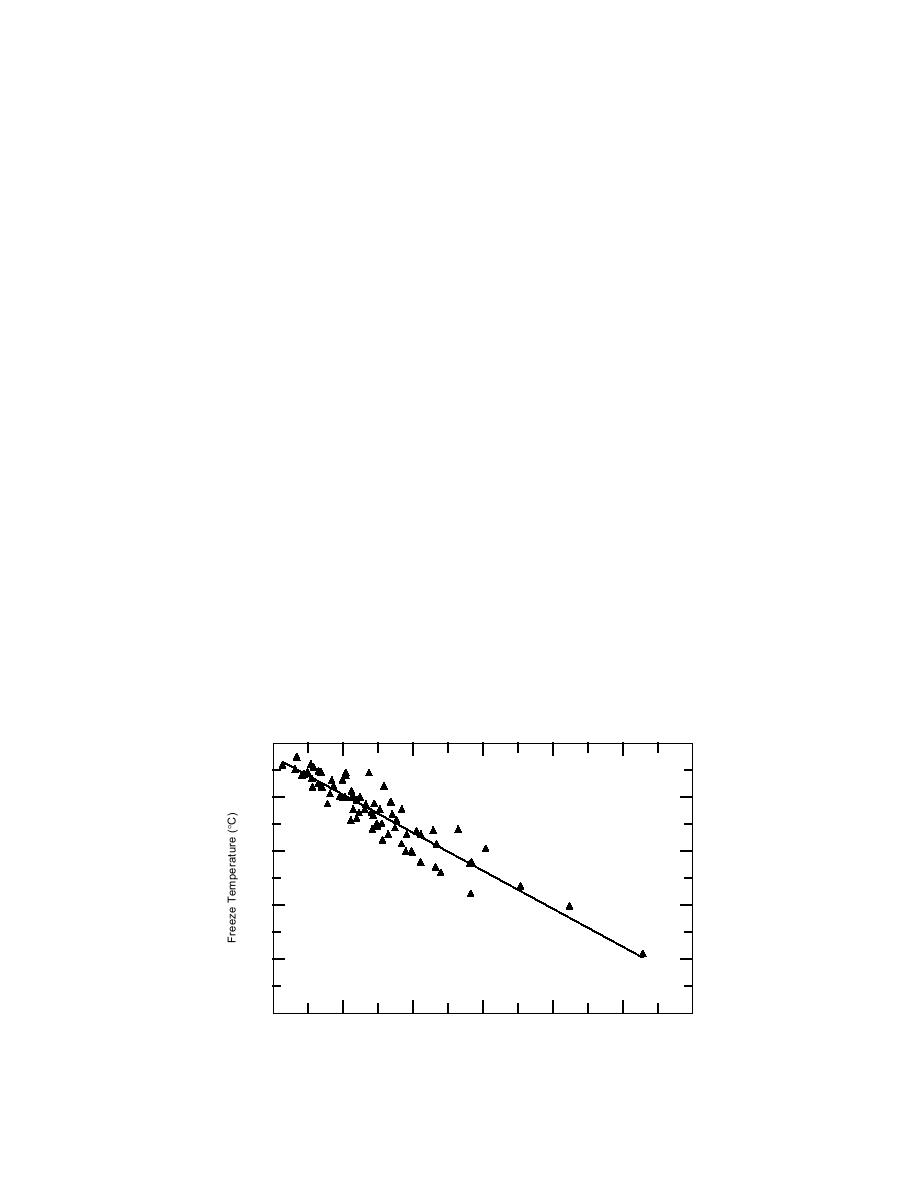

Figure 1, developed from Appendix A data,

appears to be between 4 and 8% for concrete

shows that, generally, the greater the number of

cured at 20C.

solute particles, the lower the freezing point. This

At lower temperatures, accelerator dosages

relation is independent of the type of chemical

can be higher. Calcium chloride and calcium

used, provided the chemical remains soluble at

0

-5

-10

-15

-20

-25

0

2

4

6

8

10

12

Concentration (molality)

Figure 1. Relationship between chemical dosage and freezing point.

4

Previous Page

Previous Page