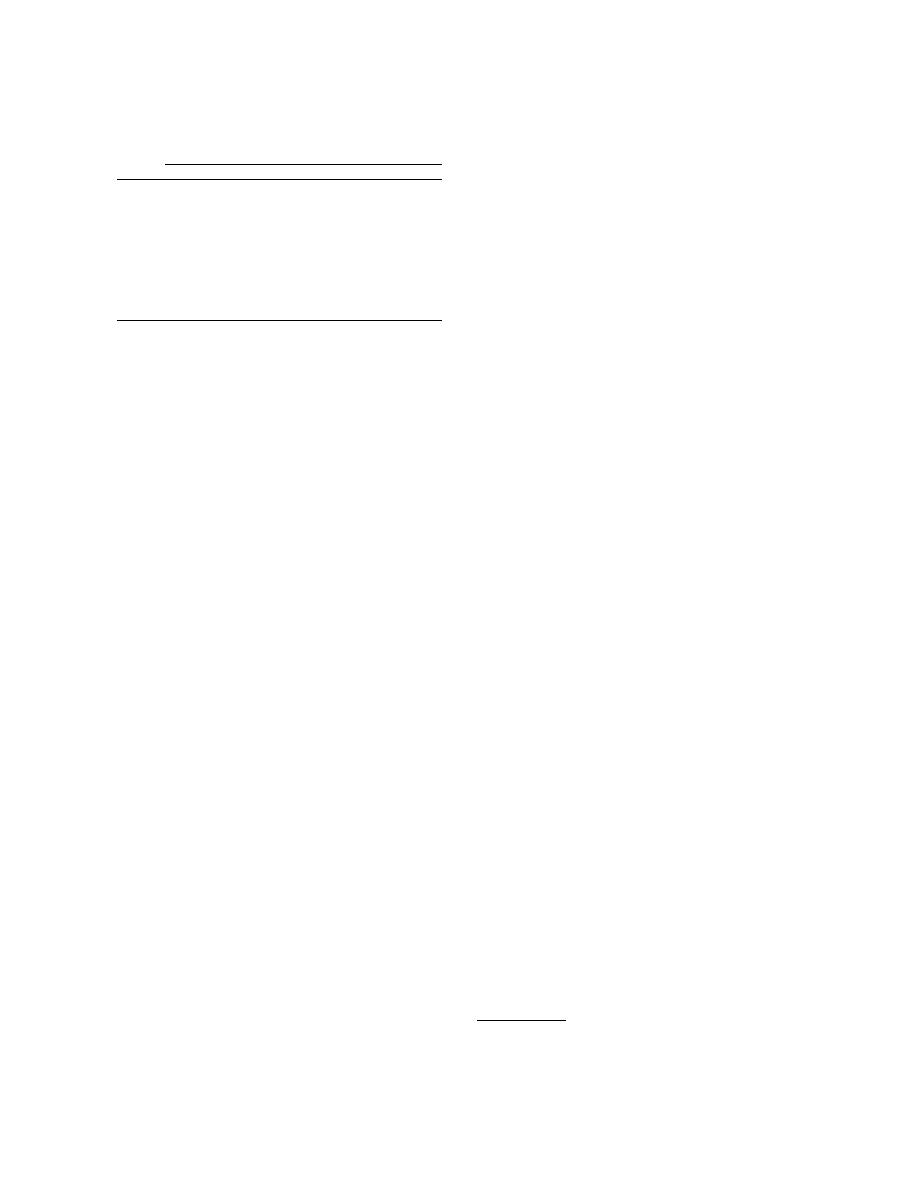

Table 1. Effect of temperature on strength gain* of

freezing point depression of mix water and the

control (admixture-free) mortar.

strength gain of mortar as a function of time and

temperature.

Strength†

Temp

(C)

1 day

3 days 7 days 14 days

28 days

56 days

Materials

50

17.7

33.6

58.1

69.3

75

77

This study used mortar as a rapid way to eval-

40

16

38.1

69.7

79.2

85

85

uate various chemicals. Mortar, instead of con-

30

13.1

36.6

72.1

87.3

94

93

20

10

30

70

90

100

105

crete, simplified mixing operations, reduced

10

3.7

15

49

75.6

97

110

material handling, and permitted smaller test

5

2

14

30.1

56.7

83

100

specimens, which meant less material had to be

5

1

6.7

14

16.6

20.3

46.8

taken to the landfill. In addition, mortar closely

10

0

0.2

1.7

2.7

4.2

51.1

20

0

0

0

0.2

0.8

37.3

simulates concrete because it has the same paste

to aggregate transition zones, except that the

* The strengths for 20, 5, 10, and 20C are results pro-

aggregate is smaller. The mortar was non-air-

duced at CRREL on 0.39 w/c mortar. The others are expected

strengths according to ACI (1988).

entrained,* used Type I portland cement at a

† Strengths are given as percentages of the 28-day strength of

1:2.75 ratio with sand, and was made with water-

control mortar cured at 20C. The mortars were cured at the

to-cement (w/c) ratios between 0.39 and 0.45 (the

temperature shown in the left most column for 28 days, then

they were cured at 20C for the remaining 28 days.

majority of the testing was at 0.41 w/c). The sand,

sieved for use in concrete, had a bulk specific

gravity (saturated surface-dry) of 2.65 and a

20C. Thus, hot weather might allow the project

moisture absorption of 1.1%. The mixing water

to go faster but it can result in permanent strength

was from the taps at CRREL.

loss.

In the long run, concrete becomes stronger

Mixing

when cured at temperatures that are low but

Mixing of the mortar followed standard labo-

above freezing. Their drawback is that they slow

ratory procedures. The mortars were mixed in a

down strength gain, which can adversely affect

Hobart mixer according to ASTM (1987) Standard

construction schedules. If concrete can be mixed

C305 with minor modifications. The chemical ad-

and protected so that its temperature can be kept

ditives were dissolved in the mixing water before

at 5C, preferably at 10C, strength gain can be

the entire solution was placed into a damp mix-

rapid enough to avoid too much delay. Table 1

ing bowl. The mixer was turned on at low speed

shows that mortar cured at 10C develops 63 and

for 30 seconds while the cement was added. The

50% less strength compared to mortar cured at

mixer was stopped, the sides of the bowl were

20C for 1 and 3 days, respectively. By 56 days,

scraped down, and mixing was resumed for 45

this strength deficit turns into a strength surplus

seconds while the sand was added. The mixer

of nearly 5%. Compared to 50C, it becomes a

was briefly stopped, changed to medium speed,

33% strength surplus. Curing at 5C produces

and run for 30 seconds. Then, the mixer was

similar results. Thus, cold weather can be the best

stopped for 11/2 minutes before finally being run

time to cast concrete.

at medium speed for 1 minute.

However, too much cold leads to problems. If

concrete freezes at an early age, it can be per-

Sample preparation and curing

manently damaged. As Table 1 shows, the 1-day

The mortar was mixed at room temperature.

strength of 5C mortar is only 10% that of mortar

Immediately after mixing it was cast into 50.8-

cured at 20C; no appreciable strength developed

101.6-mm plastic cylindrical molds, vibrated on a

at 10 or 20C. Though hydration occurs at tem-

table to ensure consolidation, capped with plastic

peratures as low as 20C, albeit slowly, less than

lids, and stored at 20, 5, 10, and 20C (some

half of the concrete's strength can be recovered by

mixes were not stored at 20C to simplify test-

thawing. Thus, cold weather protection is

ing). The samples were placed into their respec-

required to achieve strong concrete when the

tive curing rooms within 30 minutes after water

temperature dips below 0C.

TEST PROGRAM

* Non-air-entrained mortar was used intentionally to deter-

mine the effect additives have on strength development with-

The test program defined the effects of various

out having to contend with the variability of entrained air.

chemicals, singly and in combination, on the

Entrained air is recommended for field applications.

2

Previous Page

Previous Page