together. Rather than discuss each table in detail,

first came in contact with the cement. They

I summarized them into the tables and graphs

remained sealed until being tested for strength.

that follow and referenced them, as necessary, in

the text below. The reader is encouraged to re-

Test method

view Appendix A for additional detail.

Three samples of each mix from each tempera-

In reading this report, it is important to note

ture were tested in uniaxial compression accord-

that all strengths are referenced to the 28-day

ing to ASTM (1997) Standard C39 at 7, 14, 28, and

strength of control mortar cured at 20C. Table 1

56 days (some samples were not tested at 14 or 56

was organized in this manner. Likewise, Appen-

days owing to scheduling problems). Each sam-

dix A lists all strengths as percentages.

ple was capped with unbonded neoprene held

within a steel-retaining cup according to ASTM

(1993) Standard C1231. The samples from the cold-

Accelerators

rooms were allowed to thaw to 5C before being

One function of an antifreeze admixture is to

accelerate the hydration rate of portland cement.

tested.

Any increase in the early strength development

shortens the curing and protection periods neces-

RESULTS AND DISCUSSION

sary for the concrete to attain the desired

strengths. Table A1 highlights chemicals that

Appendix A shows freezing point and strength

force mortar to gain strength faster than it nor-

data for over 50 chemicals. Although many more

mally would. Table 2, extracted from Table A1,

could have been studied, I focused on a small

shows the best results.

portion of chemicals known to be compatible

It is clear that the seven chemicals shown in

with concrete. They are grouped into Tables A1

Table 2 increased the early strengths of mortar.

through A4 by their ability to accelerate the

They produced 7-day strengths at 20C that many

strength gain of mortar, by their ability to depress

times exceeded that of control mortar. In fact,

the freezing point of mixing water, by those that

compared to Table 1, they all far outperformed

are liquid, and by those that were combined

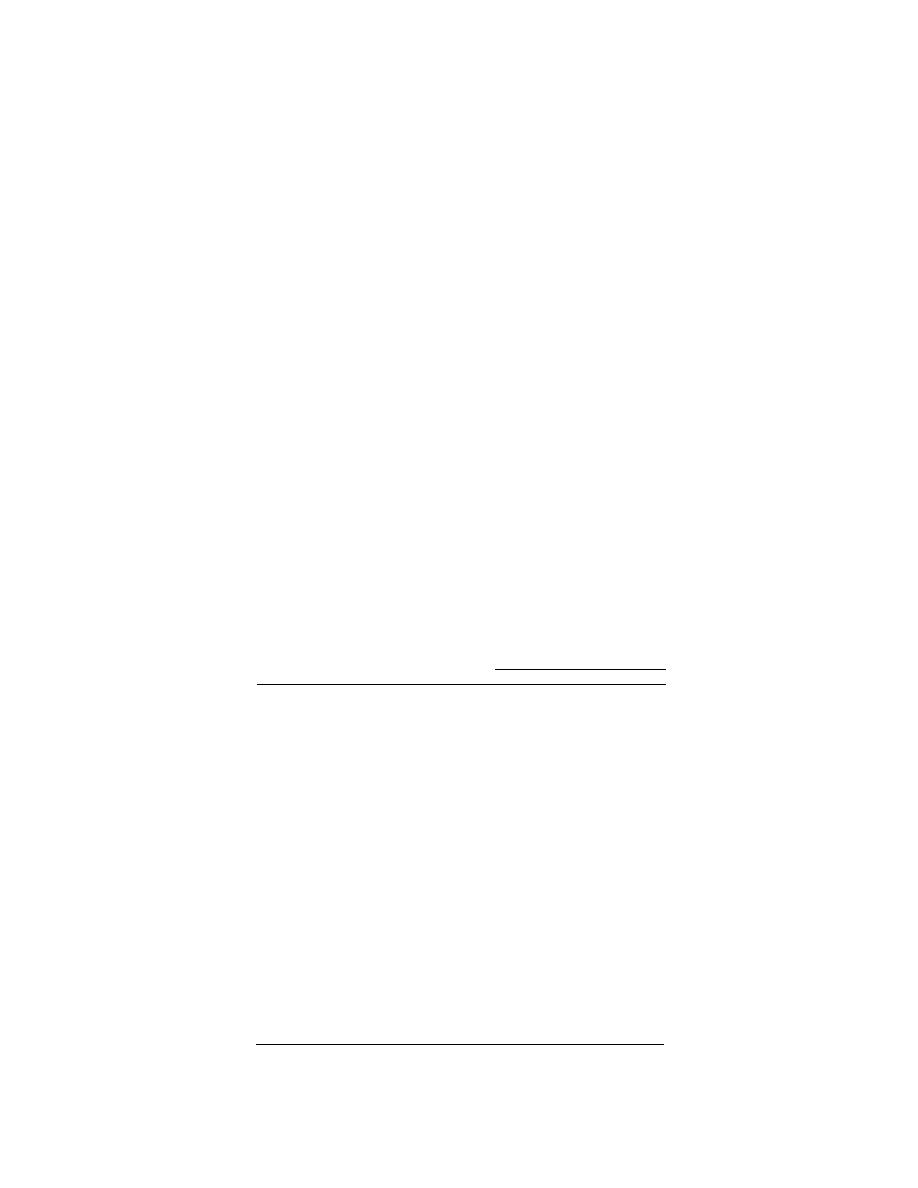

Table 2. Early age strength from the best accelerators from Appen-

dix A.

Percent by

Freezing

weight of

point

7 days*

(C)

20C

5C

10C

20C

Chemical

cement

Calcium chloride

1

2.5

108.5

10.5

1.8

na

2

3.8

109.9

19.0

3.6

na

3

6.2

108.5

30.0

5.3

na

Calcium bromide

4

2.9

108.4

4.9

3.2

0.8

6

4

109.4

11.0

6.2

1.8

na†

8

107.5

4.6

1.8

0.3

Fertilizer (calcium

3

5.3

114.3

3.8

3.4

3.4

nitrate)

6

6.7

107.9

3.2

3.1

1.9

9

8.3

96.7

6.8

6.4

5.3

Calcium nitrite

2

3.5

87.1

13.3

2.7

0.7

6

5.7

106.0

44.8

4.4

1.1

9

na

124.4

67.8

53.2

0.5

Calcium chloride

3

1.5

92.6

16.9

8.2

5.0

(deicer)

6

2.25

106.3

22.7

9.4

4.2

9

4

93.9

43.1

34.9

16.4

Calcium acetate

2

3

94.8

12.1

1.0

na

4

4.7

94.4

2.7

2.0

na

6

6.5

102.4

6.7

3.1

na

Calcium formate

2

3.3

96.2

14.4

2.0

0.2

4

4.5

91.1

17.9

3.3

0.4

6

5.5

91.7

7.3

3.3

0.7

* Strengths are given as percents of 28-day control mortar cured at 20C.

† Tests were not conducted, or information was not available.

3

Previous Page

Previous Page