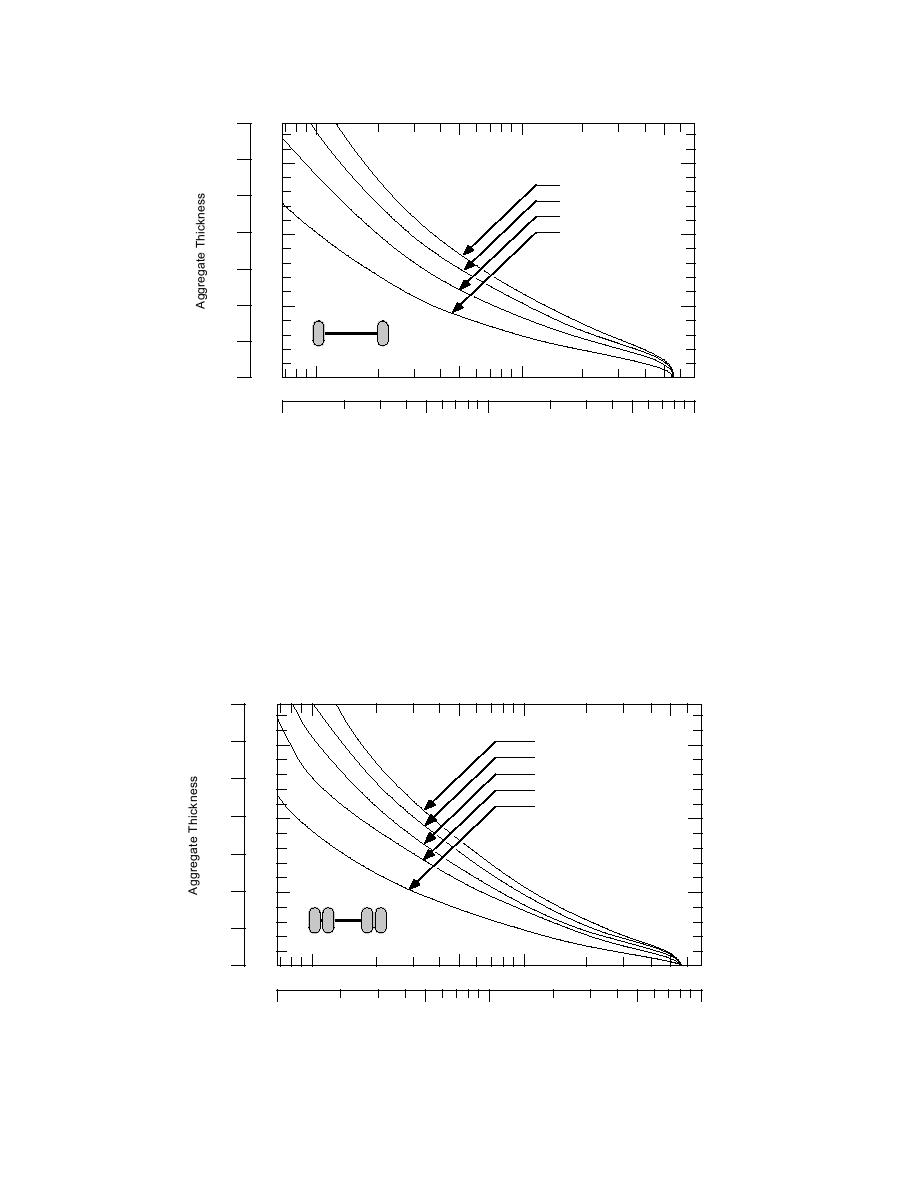

m

in.

70

60

1.5

Wheel Load, W

89.0 kN (20,000 lb)

50

66.7 kN (15,000 lb)

44.5 kN (10,000 lb)

40

22.2 kN ( 5,000 lb)

1.0

30

20

0.5

P = 2W

10

0

0

10

50

100

500

kPa

1

5

10

50

100 psi

cNc

Figure 1. Aggregate thickness design curve for single-wheel load on gravel-surface roads.

(From TM 5-818-8.)

aggregate that meets base course requirements is

evidence for the requirement of high-quality ag-

presumably required. Field Manual FM5-430-001

gregate is the fact that the design technique is

(1994) recommends that base course material have

based on experiments that used crushed-rock ag-

minimum CBR values of 80 to 100. Soils that yield

gregate (Barenberg et al. 1975).

these values include crushed rock, mechanically

Guidance for selecting wheel loads and contact

stabilized aggregates, and well-graded gravel (e.g.,

pressures to use with this design is not given in

FM5-430-001; Holtz and Kovacs 1981). Further

TM5-818-8; thus, it is now provided. For single and

m

in.

70

Wheel Load, W

60

89.0 kN (20,000 lb)

1.5

71.2 kN (16,000 lb)

53.4 kN (12,000 lb)

50

40.0 kN ( 9,000 lb)

17.8 kN ( 4,000 lb)

40

1.0

30

20

0.5

P = 2W

10

0

0

10

50

100

500

kPa

1

5

10

50

100 psi

cNc

Figure 2. Aggregate thickness design curve for dual-wheel load on gravel-surface roads. (From

TM 5-818-8.)

2

Previous Page

Previous Page