Such a system was designed at the Waterways

(1137-L) stainless steel holding tank using a bladder

Experiment Station (WES) for the treatment of

pump (Grundfus, Redi-flo2, 2-in.-diameter [5-cm-

groundwater contaminated with low levels of TCE.

diameter], submersible pump, located 20 ft [6 m]

Research into the design of this system resulted in

down the well). Groundwater could not be pumped

the use of an OPC as the sorbent and Burkholderia

directly from the well to the columns because the

cepacia (G4) as the microbe. This system was opti-

recharge rate of the well was too slow. To maintain a

mized at WES using a bench scale model unit. Once

consistent TCE concentration in the water through-

optimized, a pilot scale system was designed. Fig-

out the loading process, as well as to maintain a

ure 2 shows a schematic of the pilot scale system.

fairly constant pressure on the loading pumps, the

The objective of this work was to test and evaluate

holding tank was kept full. This was done by means

the pilot scale system and determine its feasibility as

of a siphon tube that kept the water level constant.

a cost effective alternative to current groundwater

During the loading process, the groundwater

treatment systems for TCE remediation.

was pumped from the bottom of the holding tank to

the base of each pair of columns by means of a peri-

staltic pump. The flow rate through each column

Pilot scale system and operation

The fluidized-bed adsorption bioreactor con-

was set at 120 mL/min to allow for maximum load-

sisted of a column of an adsorbent material and a

ing of the clay in the shortest time period. To ensure

bioreactor. The column was a glass tube (10 ft

that no TCE was loaded while we set the flow rate,

2-in. i.d. [3 m 2-cm i.d.]), packed with 2200 g of an

distilled water was pumped from a small carboy.

OPC material (Colloid Environmental Technologies

The groundwater was then pumped through the

Company, Clarion PM-100). The bioreactor con-

packed clay beds for 48 to 140 hours. Influent and

sisted of a 10-L glass reactor vessel fitted with a five-

effluent TCE concentrations were determined fol-

port lid, an oxygen supply, a dissolved oxygen

lowing the schedule outlined in the Sample Collec-

probe, a carbon dioxide treatment system, plus the

tion section. We defined a column to be "loaded"

draw and return lines connecting the bioreactor to

when the ratio of the effluent concentration to the

the column. The microbe used in the reactor was

Burkholderia cepacia (G4). A biotester (Liquid System

Electronic, Model LS/QA) kept the oxygen levels

between 5 and 15% of saturation. The carbon diox-

ide treatment system was a canister in which a 1-M

sodium hydroxide was circulated.

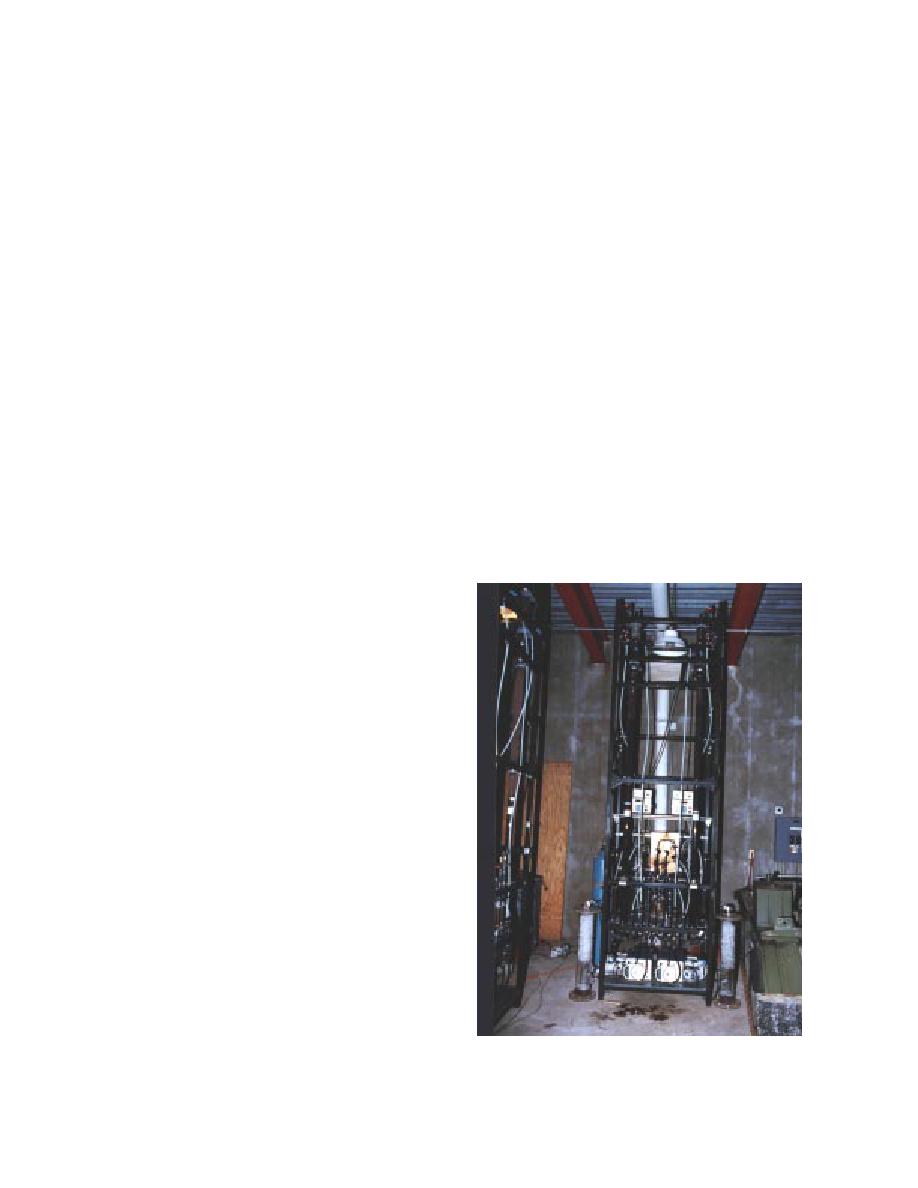

The pilot scale system was mounted on two skids

(Fig. 3), each having two adsorption columns and

the necessary plumbing for loading the columns

and providing connections to the bioreactors. The

two bioreactors were shared between these skids. A

series of peristaltic pumps (Masterflex, Inc.) were

used for loading the columns, for circulating with

water, for fluidizing the clay bed, and for removing

carbon dioxide from the reactors during remedia-

tion.

TCE-contaminated groundwater was obtained

from a site at CRREL. This is an ideal place to test

the methodology. The site is contaminated with

TCE only, so results could not be confounded by the

presence of other compounds. In addition, it is

extremely well characterized; concentrations of TCE

in the groundwater are known and are well within

the operating limits of the reactors.

The TCE-contaminated groundwater was

removed from CRREL well CECRL 11, where the

average TCE concentration was 1.52 0.18 mg/L.

Figure 3. Skid 1 of the pilot scale fluidized-bed adsorp-

To load the TCE onto the clay, groundwater was

tion bioreactor system.

pumped from the monitoring well to a 250-gallon

3

Previous Page

Previous Page