such as landfarming and composting. In this

claimed material. Rotary kiln incinerators and cir-

method, the contaminated soil is mixed with water

culating bed combustion incinerators are common

and other additives in a reactor to form a slurry. It is

types of thermal treatment (Gerace-Coles 1991).

similar to other soil and sludge biotreatment tech-

Vapor extraction technologies use an air stream to

nologies in terms of microbiological interactions

remove dissolved molecules from liquids. The vola-

and contaminant degradation pathways. However,

tile compounds are trapped out of the air stream

it differs from the other technologies because bio-

using an adsorptive material such as carbon, which

slurry systems substantially increase the rate at

is then treated by incineration. Most commonly,

which contaminants degrade by increasing the avail-

TCE is remediated through pumping and treating

ability of contaminants, electron acceptors, nutri-

it, using either air stripping or granular activated

ents, and other additives, such as surfactants, to the

carbon. These technologies are very expensive, cost-

microbial populations. The result is a biological sys-

ing

||content||

to per 1000 gallons (3785 L) of ground-

tem that is conducive to optimum microbial activity

water.

and increased contaminant degradation rates.

Bioremediation, using either bioreactors or bio-

A new bioremediation technology is now being

slurries, has been examined as an alternative to

examined for treatment of groundwater contami-

incineration. Bioremediation utilizes microbes to

nated at low concentrations--the fluidized-bed

convert hazardous substances into nonhazardous

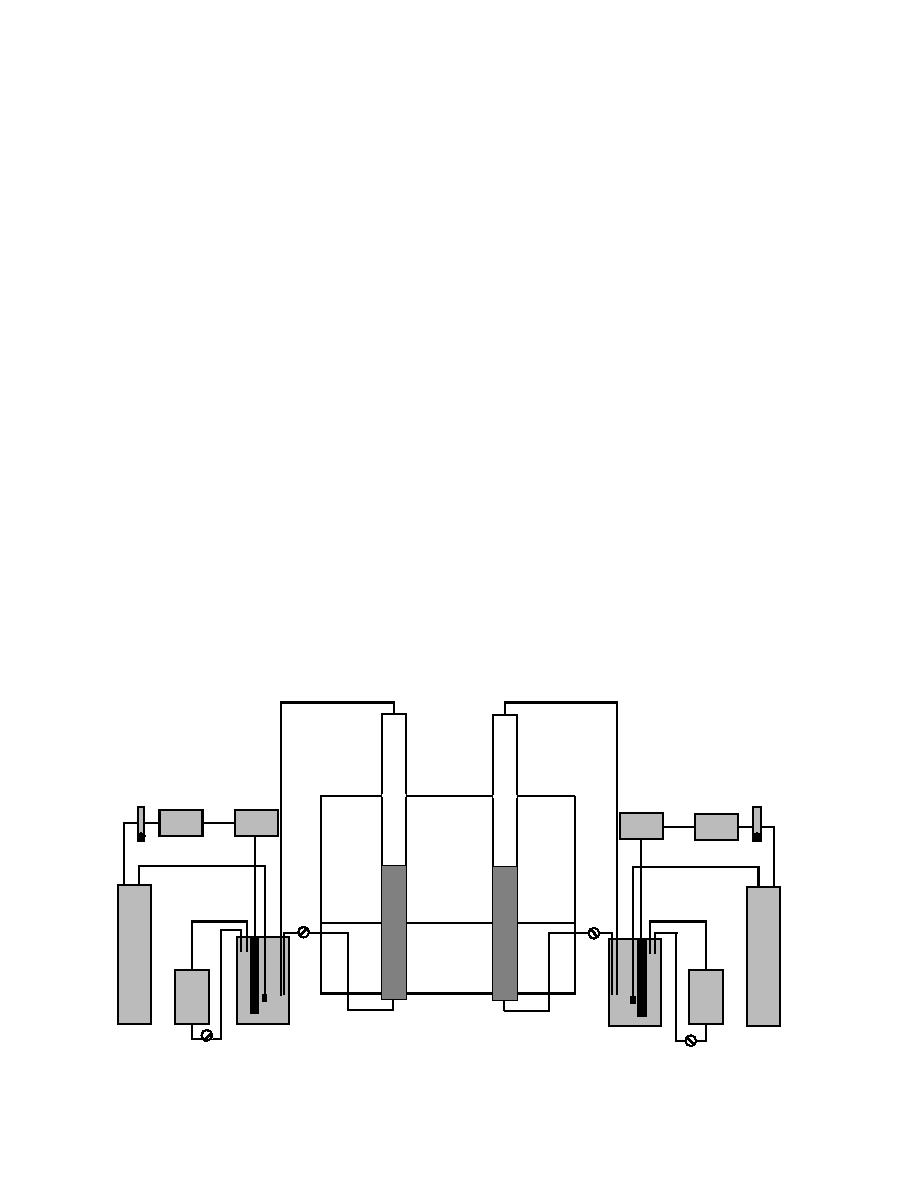

adsorption bioreactor. In this system, groundwater

compounds. The microorganism uses the contami-

is passed through a packed bed of adsorbent mate-

nant as a carbon source and ultimately converts it to

rial, such as carbon, carbonaceous resins or, organo-

CO2 and water.

philic clays (OPC). When the bed has adsorbed as

Bioreactors are large vessels in which either con-

much as it can, it is put into a closed-loop system

taminated soils or groundwater are treated. The

with a bioreactor. The bed is fluidized, meaning that

process allows for rapid bacterial growth, which

fluid is pumped through it at a high flow rate, caus-

results in maximum degradation rates. The system

ing the bed material to become suspended in the

is made optimal for a given contaminant and type

solution. As the fluid passes through the bed, it acts

of microorganism, and can be operated under either

as an extractant, removing the contaminants from

aerobic or anaerobic conditions. Once the contami-

the adsorbent material. The fluid is cycled through

nated soil or water has been remediated, it can be

the bioreactor and then back through the packed

returned to its original site as a recovered resource.

bed. Once the bed is deemed remediated, more

Bioslurry treatment of soils is a relatively new

groundwater is pumped through the sorbent and

remediation technology. It is a reconfiguration of

the process starts over.

other more widely used biotreatment technologies,

Flow

Flow

DO Meter

Meter Biotester

DO Meter

Biotester Meter

Pump

Pump

O2

O2

CO2

CO2

Reactor

Reactor

Pump

Pump

Figure 2. Fluidized-bed adsorption bioreactor.

2

Previous Page

Previous Page