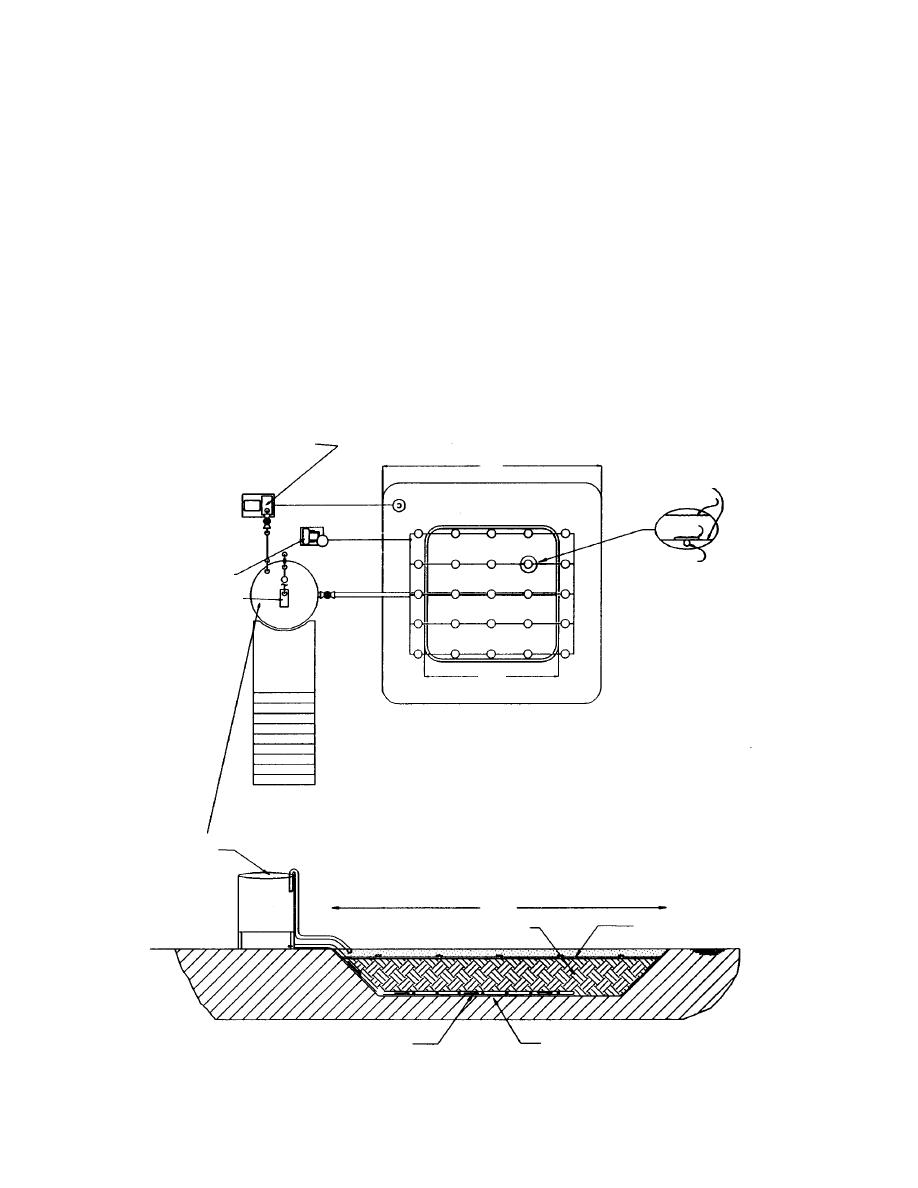

reactors. The concept is to build a lined contain-

Fe, Br, F, Pb, alkalinity, and TPH. Aromatic hydro-

ment area to serve as a bioreactor (Fig. 7). Either

carbons and nitrate analyses, which were required

a pit (generally resulting from the excavation), a

for compliance with the water discharge permit

bermed perimeter, or a combination can be used,

needed to operate of the infiltration gallery, were

depending on available materials. Contaminated

conducted by NTL.

soil is placed into the bioreactor and, through an

inexpensive PVC distribution system, aerated and

Recirculating leach bed

nutrient-amended water is recirculated into the

The recirculating leach bed is a closed-cell

bottom of the bioreactor, upwards through the

system that circulates nutrient-amended water

contaminated soil, and then through overlying

through contaminated soil. Air diffusers add

ponded and aerated water. Skid-mounted mech-

oxygen to the water. The system was designed so

that the lined cell and associated piping could be

anical systems include a mixing tank and circula-

abandoned in place once soils had been remedi-

tion pumps for water and air.

ated. The above-ground mechanical equipment,

which is the primary cost associated with this type

Design

The 26- 26-ft (8- 8-m) pit was lined with a

of system, could then be used at other locations.

Recirculating leachbeds are similar to slurry

nominal 20-mil (0.508-mm-thick), woven, black

TRASH PUMP

26'

SOIL SURFACE

WATER SURFACE

DIFFUSER

DIFFUSER

PIPING

BLOWER

16'

POND BOTTOM

MIX TANK

36'

AERATION SYSTEM

CONTAMINATED SOIL

LINER

WATER CIRCULATION SYSTEM

SCALE AS SHOWN

Figure 7. Recirculating leachbed system (1 ft = 0.3048 m).

15

Previous Page

Previous Page