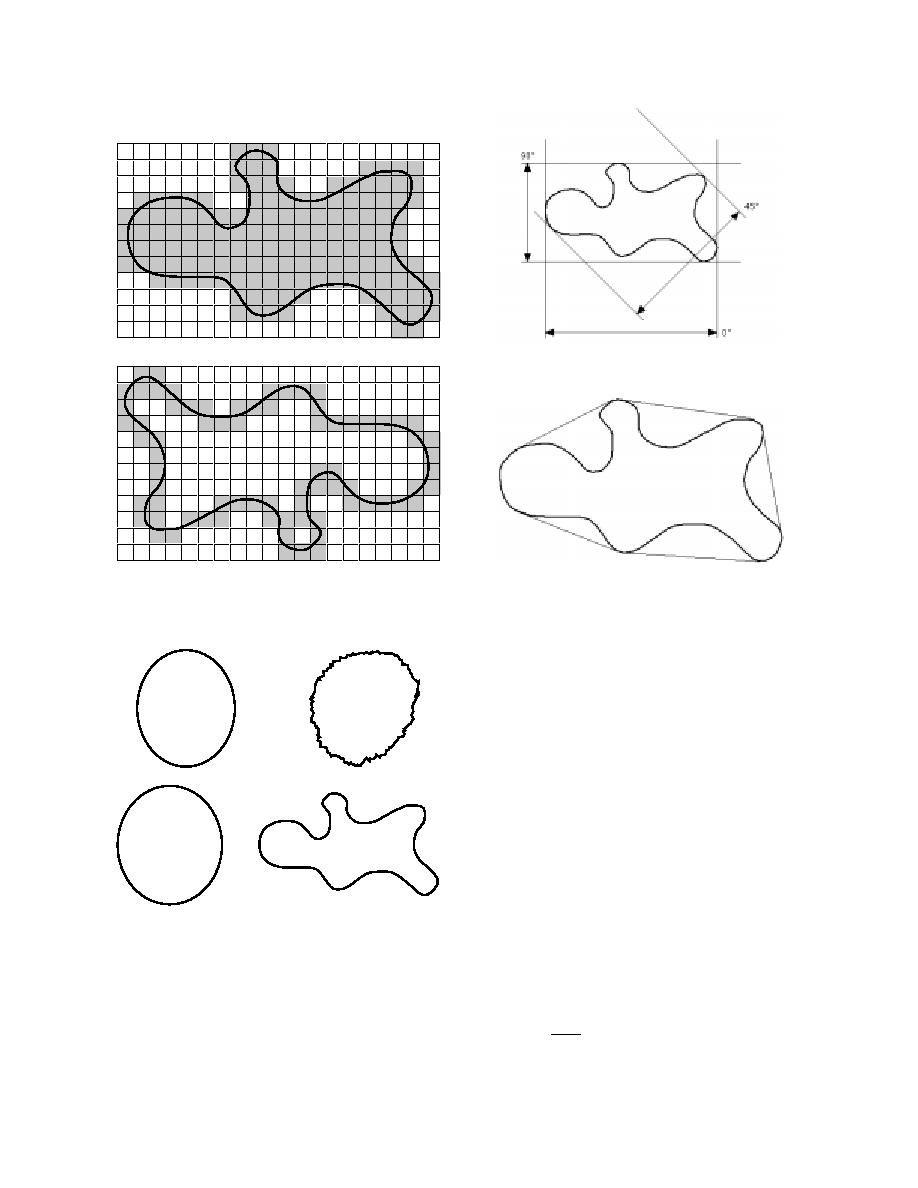

c. Typical feret measurement.

a. Area of an aggregate calculated through image analysis.

d. Illustration of convex perimeter.

b. Perimeter of an aggregate calculated through image anal-

ysis.

Figure 10. Material characterization using image analysis.

area of an aggregate is the sum of pixels present

within the aggregate boundary (Fig. 10a). The

perimeter is the sum of pixels surrounding the

aggregate (Fig. 10b). Ferets are straight-line meas-

1.00

1.12

urements made between two tangents (Fig. 10c).

In this particular case, eight feret measurements

are taken at 0, 22.5, 45, 67.5, 90, 112.5, 135, and 157.5

a. Roughness.

degrees. From these measurements, indices for

roundness and roughness are derived. For exam-

ple, the length and width of the aggregate are the

longest and shortest feret measurements taken at

95

62

the various angles mentioned above, respectively.

The roughness is defined as the ratio of the

perimeter to the convex perimeter. The convex

perimeter is defined as the string measurement

b. Roundness.

around the tips of the eight ferets (Fig. 10d). For a

smooth material, the roughness factor equals

Figure 11. Definition of roughness and roundness.

1.00. As the roughness increases, the roughness

factor also increases (Fig. 11a).

The numbers on these figures are used to iden-

The roundness is defined as follows:

tify the measurements of the individual aggre-

gates during the analysis process. The following

4πA

Rn =

basic measurements were made: 1) feature area,

P2

2) feature perimeter, 3) feature ferets, and 4) x-y

coordinates. In the image analysis method, the

where Rn = roundness index

6

Previous Page

Previous Page