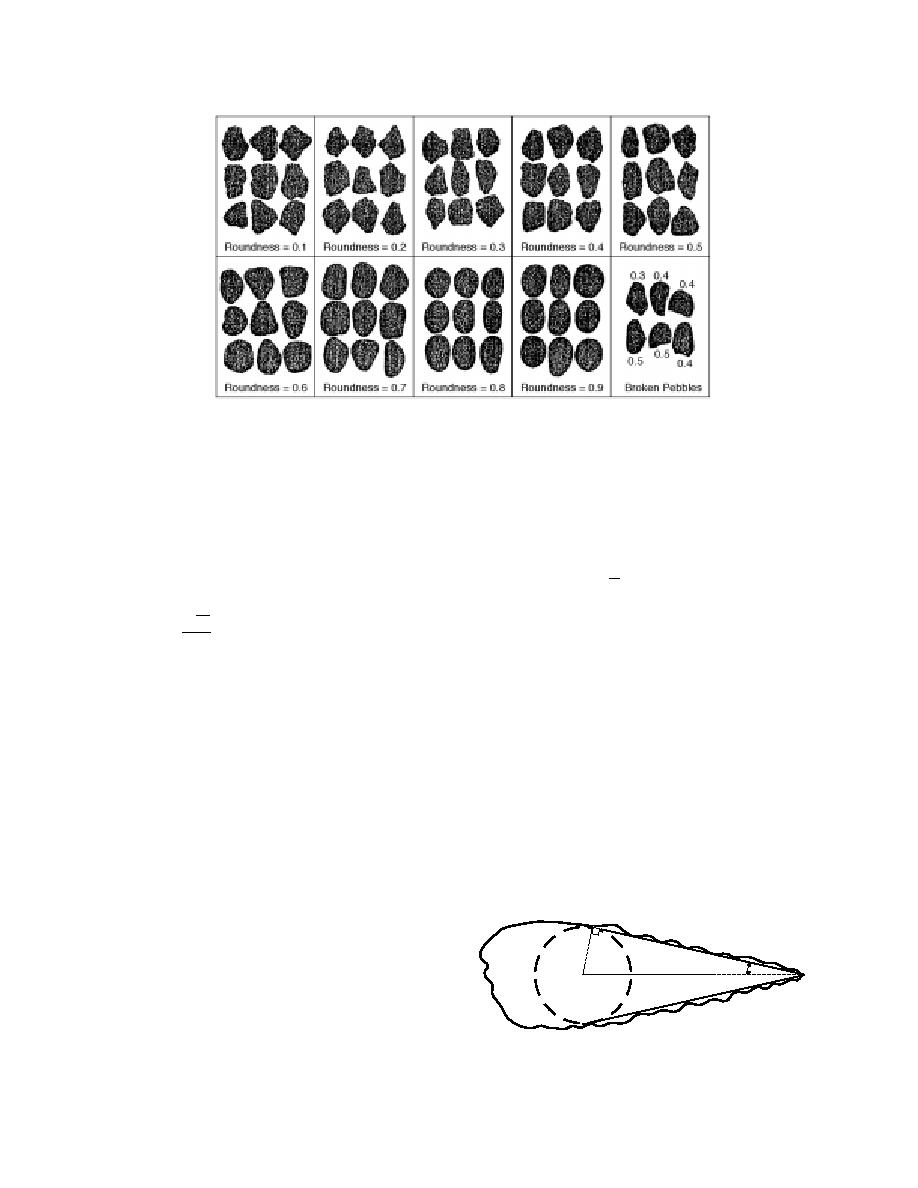

Figure 2. Roundness chart for 16- to 32-mm aggregates. (After Krumbein 1941.)

crushed aggregates. Lees (1964) proposed a meth-

the edges and corners of the particles also are

od for determining the degree of angularity, which

determined. These radii are used to index the

accounts not only for the roundness of the corner

roundness of the aggregate as shown below.

but also how far the projection is from the in-

Details on this method can be found in the papers

scribed circle (Fig. 3). The degree of angularity is

by Wadell (1932) and Krumbein (1941). Essen-

calculated by the following equation:

tially, the roundness (R) of a particle is an average

measure of curvature of the corners and edges. R

x

Ai = (180 a)

is expressed as

r

r

where Ai = degree of angularity

∑

R = r′

a = measured angle

N

x = distance to the tip of the corner from

the center of the maximum inscribed

where r = radius of curvature of a corner of the

circle

particle surface

r = radius of the maximum inscribed circle.

r′ = radius of the maximum inscribed cir-

cle in the projected plane

The total degree of angularity (A) is the sum of all

N = number of corners.

the values for all corners measured in three mutu-

ally perpendicular planes. Again, because of the

Because this is a lengthy process, visual charts

high degree of complexity, Lees (1964) developed a

have been developed (Krumbein 1941) for esti-

visual chart for determining the degree of angular-

mating the roundness of aggregates. Figure 2 can

ity of particles (Fig. 4).

be used to classify the roundness for 16- to 32-mm

ASTM D 2488-90 (1996), Standard Practice for De-

aggregates. By enlarging or reducing the chart,

scription and Identification of Soils (Visual-Manual

similar roundness charts could be made for other

Procedure), describes the angularity of coarse-

size aggregates (Krumbein 1941). The roundness

grained material as either angular, subangular,

(R) varies between 0.1 and 0.9. An R value greater

than 0.6 indicates high roundness, R between 0.4

and 0.6 indicates medium roundness, and R less

than 0.4, low roundness.

r

α/2

x

Description of angularity

Inscribed

Lees (1964) found that when using Krumbein's

Circle

(1941) method for determining the roundness

Aggregate

number, it was possible to get the same round-

Figure 3. Parameters for determining the degree of

ness number for two very differently shaped

angularity. (After Lees 1964.)

aggregates. He found to it to be especially true for

3

Previous Page

Previous Page