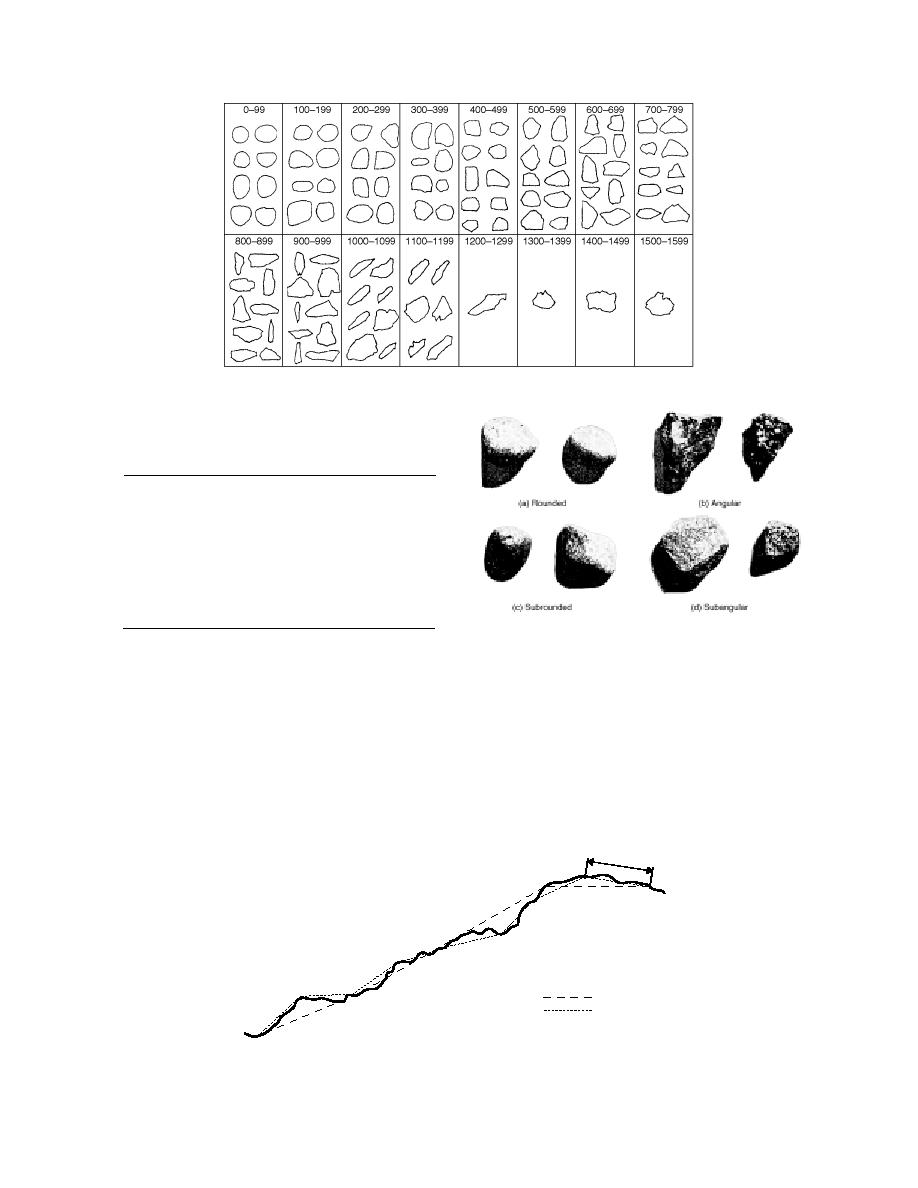

Figure 4. Degree of angularity chart. (After Lees 1964.)

Table 3. Criteria for describing angularity of

coarse-grained particles (ASTM D 2488-90).

Description

Criteria

Angular

Particles have sharp edges and relatively

plane sides with unpolished surfaces.

Subangular

Particles are similar to angular description

but have rounded edges.

Subrounded

Particles have nearly plane sides but have

well-rounded corners and edges.

Rounded

Particles have smoothly curved sides and

no edges.

Figure 5. Visual identification of aggregate angularity.

(After ASTM D 2488-90.)

subrounded, or rounded. The qualitative criteria,

presented in Table 3, are used for describing the

scale to determine the surface texture (roughness)

angularity. A visual chart for determining the

of aggregates. The surface roughness (SR) was

angularity of the aggregate, similar to that found

based on visual inspection and indexed to a scale

in ASTM D 2488-90, is presented in Figure 5.

ranging from 0 (for glassy particles) to 1000 (for

very rough particles).

Description of surface texture

Another method found in the literature was to

The surface characteristics or texture of an

coat a flat, sawed aggregate surface with asphalt

aggregate are considered to have an effect on the

(Bikerman 1964), which is then scraped to the sur-

engineering response of the material. Terzaghi

and Peck (1967) defined texture as the degree of

fineness and uniformity. They suggested qualita-

4.9 cm

tive expressions such as smooth, sharp, gritty,

etc., to describe the texture.

Barksdale and Itani (1994) used a roughness

8 cm chords

4 cm chords

Figure 6. Measurement method for characterizing the surface texture of

an aggregate. (After Wright 1955.)

4

Previous Page

Previous Page