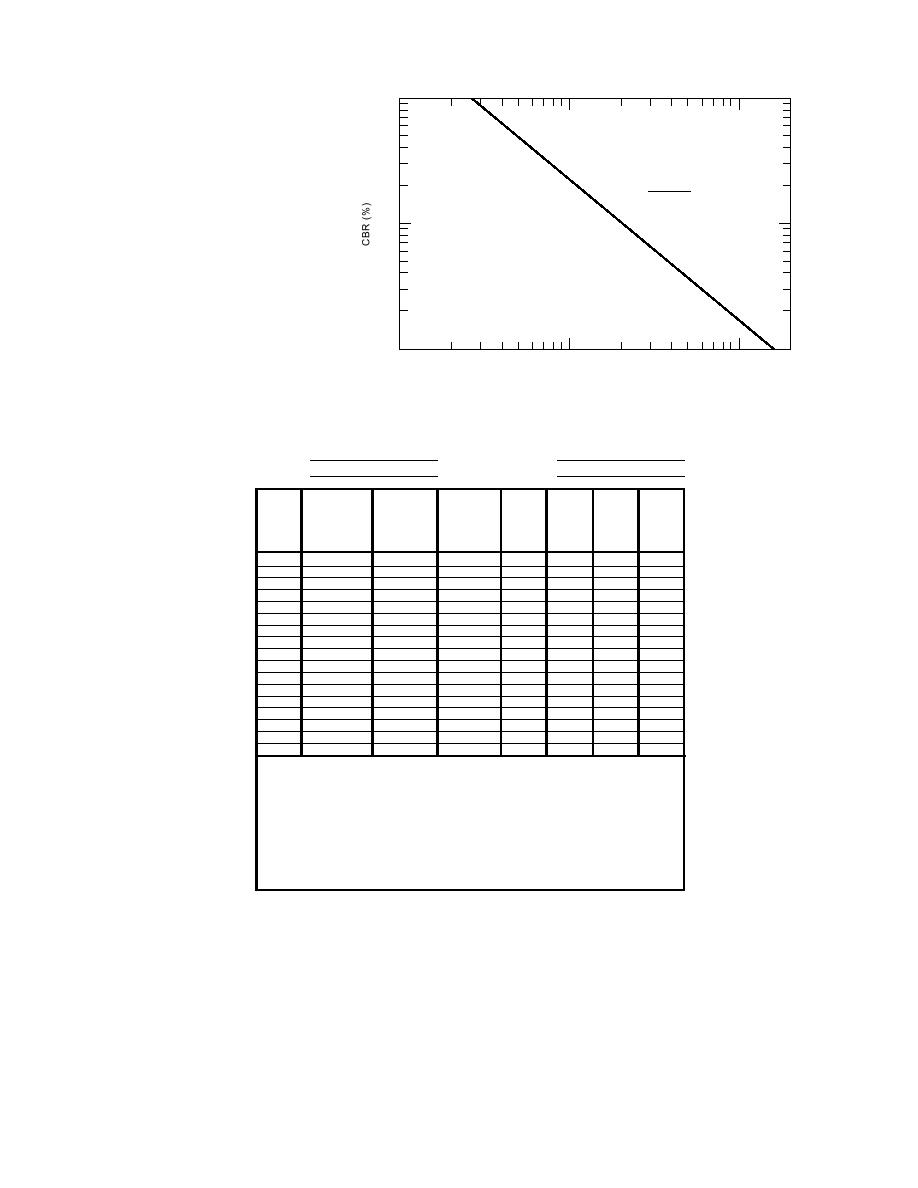

the correlation of CBR vs. DCP to

100

produce eq 3:

CBR = 292/DCP1.12.

(3)

The DCP data are recorded as the

292

CBR =

number of blows needed to drive

DCP1.12

the penetrometer in increments of

10

not less than 25 mm of penetra-

tion. Figure 8 (Kessler Soils Engi-

neering Products 1996) is a sample

of a typical data sheet. When the

maximum penetration has been

reached, the DCP is removed from

the hole by driving the sliding

1

weight against the top handle.

1

10

100

200

Disposable cones were used dur-

DCP Index (mm/blow)

ing the spring field testing to min-

Figure 7. Correlation plot of CBR vs. DCP index.

imize wear and tear on the equip-

ment.

RayayararSupereufndd See

R mmk k Sup fr un Sitit

March 12,, 1997

h 12 1997

Projroject

P ect

Datte

Da e

LoLociatnon Siteit3 Norohth +000

S e 3 N t r 0 0+0

stabiliized wasttemateeiraal

zed wase mat r i l

cat o i

SoiilType(s)

Sol Type

No. o.fofAccccumulavie e Penetrtatition Peenerraton Hamm er

No

A umulati t v Pene raon P nettatiion Hamm

DCP

CBR

Deephh

D ptt

CBR

bws s penetearaoin n per r loow set peerblow

low

penr t ti t o

pebblw set

p r blow

bllow

b ow

index

index

((%)

%)

(in))

blo

(in

(mm)

(mm)

(mm)

f actor

factor

(mm)

(mm)

(mm)

(1)(1)

(2(2)

(3) )

(3

(4))

(4

((5)

5)

(6)

((7)

7)

(88)

()

)

(6)

0 0

00

------

-----

---

1

-----

---

00

----

--

1

----

3 3

25 5

2

255

2

8..3

83

1

27

1100

..

8.3

1

27

8.3

1010

55 5

5

300

3

330

..0

1

85

2.2

3.0

1

85

2.2

3.0

10

80

25

2.5

1

105

3.1

2.5

10

80

25

2.5

1

105

3.1

2.5

10

110

30

3.0

1

85

4.3

3.0

10

110

30

3.0

1

85

4.3

3.0

15

150

40

2.7

1

97

5.9

2.7

15

150

40

2.7

1

97

5.9

2.7

10

190

40

4.0

1

62

7.5

4.0

1010

190 0

400

440

..0

1

62

9715

..

4.0

23

4

1

62

4.0

1010

230 0

400

440

..0

1

62

10 1

9..6

4.0

27

4

1

62

4.0

1010

270 0

400

460

..0

1

62

11006

3. .

4.0

33

6

1

39

6.0

1010

330 0

600

660

..0

1

39

15. .

1340

6.0

39

6

1

39

6.0

10 8

390 5

605

650

..6

1

39

11514

7. .

6.0

43

4

1

42

5.6

8 8

435 0

455

556

..6

1

42

18. .

1791

5.6

48

4

1

42

5.6

8

480

45

5.6

1

42

18.9

5.6

(1)

No. of hammer blows between test readings

(1)(2)

No.ccfuhaulative lconespbetwreeinnester eachgset of hammer blows

A o m mmer bow enet at o t af readin s

(2)(3)

Acciufmrulncieencaccumunattiratipenafttrertiench)sattstartamd end lofws mmer set

D f e eat v i one pe l e ve on e a oa (2 e of h anmer b o ha

(3)(4)

Di(ferdincdeid by c1)mulative penetration (2) at start and end of hammer set

f3) e vi e n ac( u

(4)(5)

(3) ditvir 1doby 716 lb hammer; 2 for 10.1 lb hammer

En ede f r 1( . )

(5)(6)

Enterx1(5)r 17.6 lb hammer; 2 for 10.1 lb hammer

(4) fo

(6)(7)

(4) xo(5)CBR versus DCP correlation

Fr m

(7)(8)

FrPm vious entry is DCPiviorrdlation .4 rounded off to 0.1 in.

ore CBR versu n (2) d c dee by 25

(8)

Previous entry in (2) divided by 25.4 rounded off to 0.1 in.

Figure 8. Example of completed DCP data sheet for the Raymark Superfund site.

in January. The data gathered from the thermo-

TEMPERATURE DATA AND ANALYSIS

couples were used to determine whether 910 mm

of material was a sufficient thickness to prevent

Thermocouples were installed at the site in

frost penetration into the stabilized waste mater-

December/January at four locations (see Fig. 1:

ial.

thermocouple sites 10, 20, 30 and 40) and recorded

At sites 10 and 20, the thermocouple strings

data throughout the freezing season. Thermocou-

were installed into the Tilcon common granular

ples were installed during December at sites 10,

fill material. Site 30 was located in another sub-

20 and 30. Site 40 was installed during a site visit

5

Previous Page

Previous Page