water to reduce salt accumulation. Ten times dur-

ing the experiments leachates were collected and

analyzed for pH and heavy metals. The plants

were harvested on 23 April 1996, rinsed in deion-

ized water, and separated into shoots, crowns,

and three root samples from the three soil zones.

The plant material was frozen until ready for

analyses.

Leachates were analyzed for Zn, Pb, Cu, Cd,

and pH. Samples were refrigerated after samp-

ling, but were not filtered. There was no visual

evidence for any significant movement of sus-

pended material or organics as judged by settling

out of suspension or discolored solutions. Work-

ing standards for heavy metals were prepared

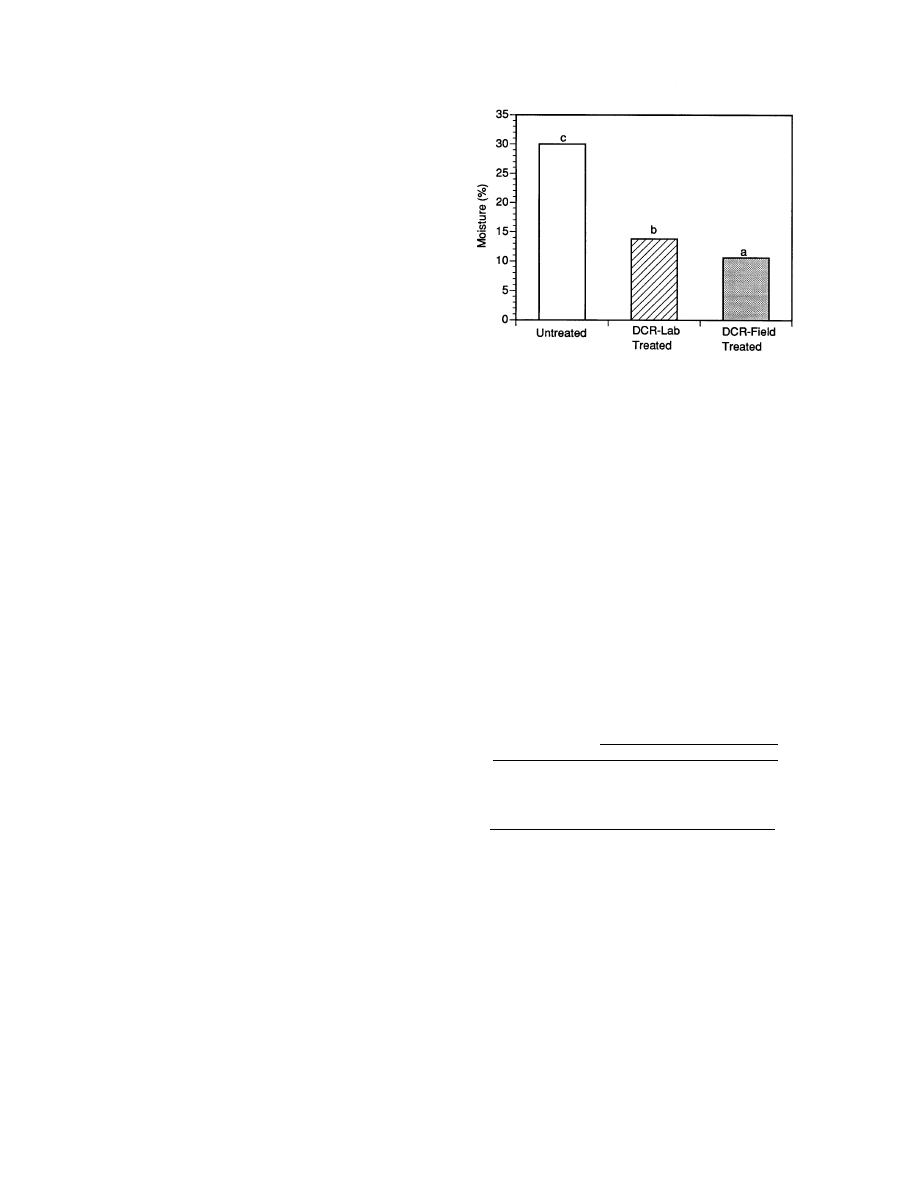

Figure 2. Water content of untreated soil-asphalt tar

from 1000-ppm Fisher primary standards. A

and laboratory and field DCR-treated material.

Perkin-Elmer Model 5000 atomic absorption

spectrophotometer (AAS) was used for the heavy

The hydraulic conductivity was determined

metal analyses. The pH meter was calibrated

on three DCR-treated asphalt tar samples sub-

with Fisher standards at pH = 10.00 0.02 and pH

jected to a single freeze-thaw cycle. Although the

= 7.00 0.01.

hydraulic conductivity increased with a single

The plant material was dried in an oven at

freeze thaw cycle, the difference was not signifi-

80C, then ground in a stainless steel Wiley mill to

cant (Table 3). Because of the high levels of sand

pass a 20-mesh screen. Subsequent plant process-

and gravel in the raw waste, the DCR-treated tar

ing for heavy metal analyses closely followed the

material was coarse-textured. As a consequence,

procedures used by Brown et al. (1994). Briefly,

the hydraulic conductivity was high (Table 3).

plants were ashed at 480C for 16 hours, digested

Reduction of hydraulic conductivity to a regula-

tory limit of 1.0 105 cm s1 for some applica-

with 5 mL of concentrated HNO3, evaporated to

dryness, taken up in 5 mL of 3 M HCl, and then

tions (e.g., landfill covers) will necessitate mixing

diluted to volume (25 mL) with 1 M HCl. Blanks

of the treated material with finer-textured silts

were carried through the identical process. These

solutions were analyzed on a Perkin-Elmer

Table 3. Changes in hydraulic conductivity

model 5000 AAS. Working standards were pre-

after one freezethaw cycle.

pared from primary standards (Fisher, 1000 mg

Dry

L1) and contained the same HCl concentrations

Hydraulic conductivity (cm sec1)

Sample

density

as the samples to assure a similar sample matrix.

(g cm3)

no.

0

1

Ratio

1.03103

1.12103

1

1.41

1.09

RESULTS AND DISCUSSION

5.76104

9.85104

2

1.36

1.71

2.06104

2.67104

3

1.37

1.30

Shemya study

6.04104

7.91104

Mean

1.38

1.37

This study involved more physical testing of

the treated material than the subsequent studies,

and clays. A single freeze-thaw cycle increased

because there was interest in possibly using this

the hydraulic conductivity by 37% (Table 3),

material for either road subgrade or in a landfill

which agrees with Chamberlain (1994) who

cover in an area subject to freeze-thaw cycles.

found that the hydraulic conductivity of most

The water content of untreated asphalt tar was

compacted clays increased significantly after

around 30% by weight; both laboratory and field

freezing and thawing. Chamberlain (1994) re-

DCR-treated asphalt tar material contained sig-

ported that freeze-thaw cycles are the major prob-

nificantly less moisture (Fig. 2). This dehydration

lem affecting the design and performance of

of the treated material is partly due to formation

landfill containment structures and surface im-

of Ca(OH)2 and partly due to release of steam in

poundment systems in cold regions. The coarse

the exothermic reaction (eq 1). The laboratory

texture and high hydraulic conductivity of this

treated material contained significantly higher

DCR-treated tar-soil mixture may limit potential

water compared to field treated material.

reuse.

8

Previous Page

Previous Page