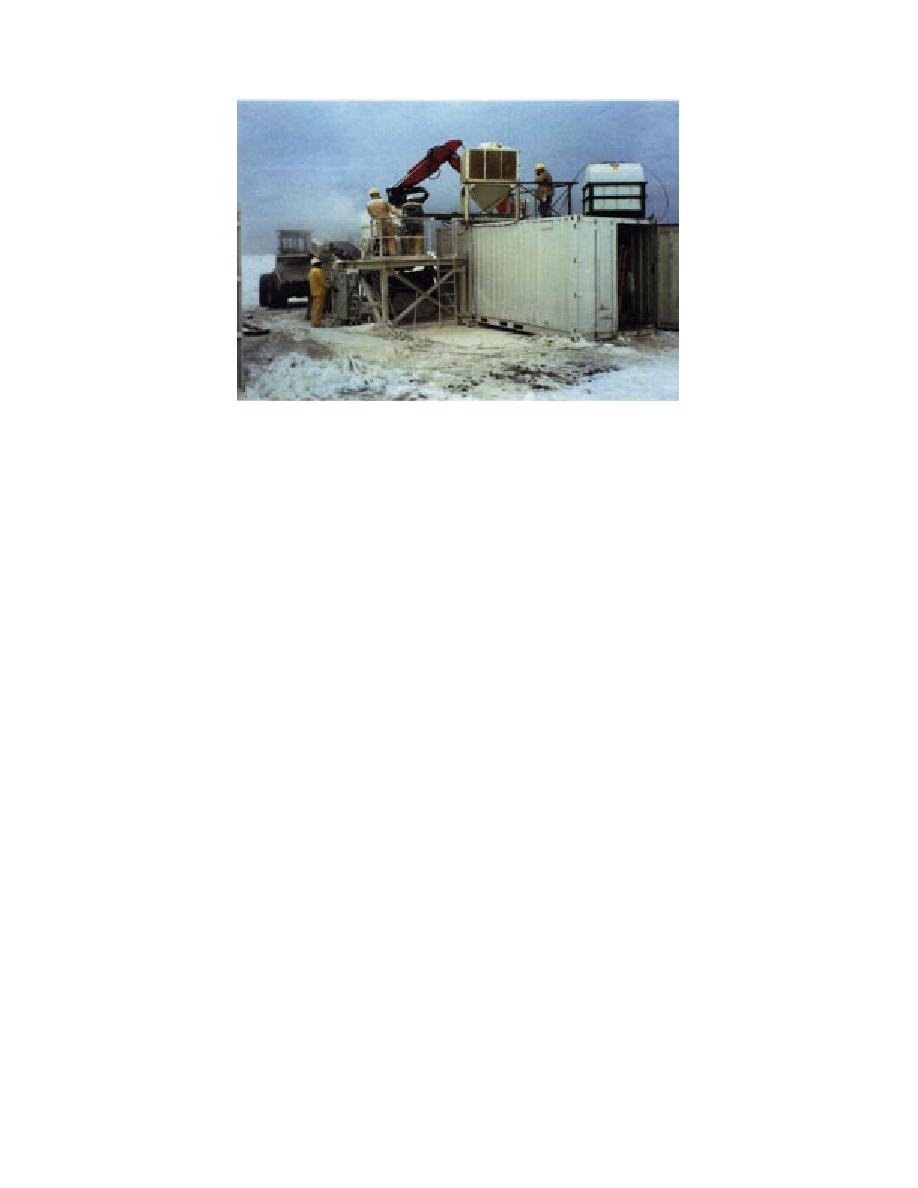

Lime-feed

Apparatus

Water

Mixer

↓

Conveyor

↓

↓

Control Panel

Figure 1. Transportable treatment unit used on the Shemya study.

Shemya Island is dominated by a persistent

is contaminated with JP4 and other volatile

low pressure system known as the "Aleutian

fuels; and 3) Fire Training Pit, which is contamin-

Low." Frequent storms track across the north

ated with diesel residuals that were not volatil-

Pacific into the Aleutian Islands. The Aleutian

ized or burned during fire training exercises.

low pressure cells are responsible for the relative-

SOUND Environmental Services (now known

ly mild maritime climate of the Aleutian Islands.

as SOUND/epic), Anchorage, Alaska, under con-

Summer fogs are severe and preclude any flying

tract with the U.S. Army Cold Regions Research

as often as one day in four. The persistent wind,

and Engineering Laboratory (CRREL), demon-

fog, and salt spray are responsible for the highly

strated the DCR technology at Eareckson AFS,

corrosive and harsh conditions.

Shemya. To treat the asphalt tar waste, SOUND

The mean annual temperature is 3.6C. The

used a skid-mounted transportable treatment

minimum and maximum recorded temperatures

unit (Fig. 1). The transportable treatment unit

are 13.9 and 17.2C, respectively. The diurnal

consists of a control panel, mixer, lime-feed appa-

temperature variation rarely exceeds 6C. Mea-

ratus, water container, and conveyer assemblies.

surable winds are recorded 363 days yr1 with a

Asphalt tar was excavated with a Link-Belt exca-

mean annual wind velocity of 32 km hr1. Wind

vator and stockpiled on the site. The excavated

direction is evenly distributed without any true

asphalt tar material and accompanying soil were

prevailing wind direction. Precipitation occurs

added to the pug-mill mixer on a volumetric basis.

more than 330 days yr1. Average annual precipi-

Lime was metered into the mixer on a timed basis

tation is 79.5 cm. The average annual snowfall is

dependent on the volume of waste addition.

178 cm. Drifting snow and driving rain are com-

Occasionally water was also added to the mixture

mon in winter because of strong wind velocities

at the discretion of the mixing overseer.

(CH2M Hill 1990).

Two bulk soil samples (18 kg each) for labora-

Eareckson AFS has several types of soil con-

tory physical tests were collected by mixing dif-

tamination problems which are the result of his-

ferent batches of DCR-treated asphalt material in

toric and ongoing USAF operations. The primary

the field. These samples were air-freighted to

focus of this study was on a site identified as the

CRREL without any special provisions for preser-

PS-9 Asphalt Tar Drum Storage Area. This site is

vation. Three soil samples were used in the phys-

contaminated as a result of leaked asphalt tar

ical tests. Samples 1 and 2 were from the two sep-

stored in 55-gal. drums. In addition, we exam-

arate buckets, and sample 3 was a composite

ined, at the laboratory scale, the efficacy of the

sample from the two buckets.

DCR process to remediate organic-contaminated

ASTM Method D 508490 was used to deter-

soil from three sites identified as 1) Oil/Water

mine the saturated hydraulic conductivity (per-

Separator Pond Sediment, which is contaminated

meability) of DCR-treated asphalt tar materials

with oils and greases; 2) Cell 21 Oiled Peat, which

before and after one freezethaw cycle. Rocks

4

Previous Page

Previous Page