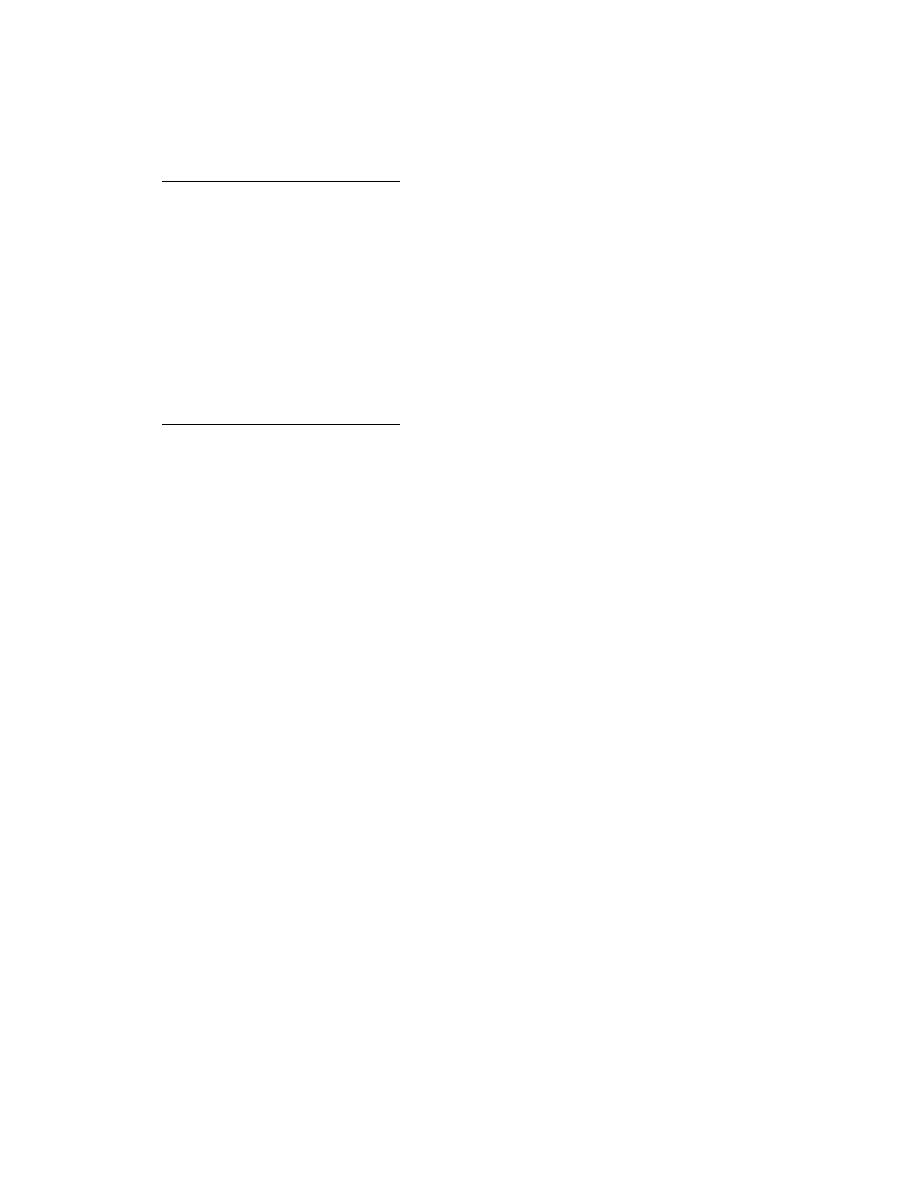

Table 2. Descriptive chemical charac-

stabilization approaches) achieves its greatest

terization of RMA Basin F liquid*

technological advantage with wastes containing

very high (> 1030%) levels of organics (e.g., die-

(highest historical data).

sel oil residuals and waste oils) because such ma-

Constituent

mg/L

terials facilitate transfer of the contaminants of

Water

620,000

concern onto the hydrophobic CaO reagent be-

fore the dispersion by chemical reaction takes

Major metals

Sodium (Na)

65,000

place. It was apparent that there would not be

Copper (Cu)

5,860

sufficient free organic (oily) phase in the sludge/

Potassium (K)

2,900

soil matrix for optimum DCR processing. It was

Major inorganics

determined in a wettability study that addition of

Chloride (Cl)

159,000

a benign food additive (Archer Daniels Midland

Ammonia (NH3)

60,900

[ADM] regular soy oil soap stock) at 10% of soil

Sulfate (SO4=)

27,000

weight significantly improved the water repel-

Total phosphorus

16,200

Nitrate (NO3)

1,300

lency of the resultant product, so its addition was

implemented as a standard procedure for all fur-

Additional components

ther tests.

Urea

143,000

Dimethylmethylphosphonate

2,000

Following the initial scoping studies completed

in the first week after sample receipt, 0.7-kg scale

* From R.F. Weston Document 1212WG.APA

(12/17/90).

batch preparations were undertaken to generate

sufficient DCR-treated material for independent,

addition to significant levels of pesticides, the

third-party laboratory testing. The initial DCR

Basin F Liquid (later mixed with clean soil to yield

product prepared for outside laboratory analyses

the "soil-amended Basin F sludge") contained

was generated from 55% CaO addition to lime-

very high concentrations of inorganic salts [e.g.,

milk pretreated soil plus 10% ADM soy oil. The

NaCl, NH4Cl, and (NH4)2SO4] as well as 14% urea

total CaO reagent requirement (including that

(Table 2).

used to generate the lime milk slurry) for this

It was determined that the high levels of sulfate

sample was 64.7%. This material and a sample of

(and possibly urea) in the waste (Table 2) were

the raw untreated waste soil were packaged for

interfering with the CaO hydration inherent to the

shipment and transferred under chain of custody

DCR process. As a result, uneconomically high

to the Environmental Lab. The following analy-

levels of CaO reagent were required to obtain an

ses were performed: FID GC (Diesel Range Total

acceptable product. To circumvent this problem,

Petroleum Hydrocarbon Screening, EPA Method

additional tests were undertaken to see if the waste

8015M), ECD GC (EPA Method 8081, Pesticide and

could be pretreated with lime milk [hydrated

PCB Analyses), GC/MS (EPA Method 8270, Total

Ca(OH)2] to tie up the sulfate (for example as gyp-

Waste Analyses), TCLP (EPA Method 1311 Extrac-

sum, CaSO4.2H2O) and also remove the urea.

tion for Pesticides, EPA Method 8081).

These tests were very successful, and it was found

Subsequent to sample shipment, several addi-

that addition of 30% lime milk slurry in H2O

tional larger-scale (1.5 kg) scoping experiments

[Ca(OH)2 at approximately 1013% of contamin-

were completed with SOUND/epic's high inten-

ated soil weight] was sufficient to tie up all the sul-

sity Eirich Mixer. Through these later determina-

fate as gypsum. Then with subsequent addition of

tions, it was found that at the larger batch size

dry CaO for the DCR reaction, it proceeded with-

and with more aggressive mixing, an acceptable

out delay and at economically feasible reagent

product could be obtained with only a 23% CaO

addition levels. The lime milk pretreatment also

addition to lime-milk pretreated soil (total CaO

proved to be an excellent way to remove ammonia

addition, including preparation of lime milk was

by volatilizing any ammonium originally present

27.4%). Because the 27.4% CaO addition is more

as ammonium sulfate and catalyzing the hydroly-

representative of what might be utilized in field

sis of urea to CO2 and ammonia. In field applica-

applications, samples of this DCR-treated mater-

tions, this approach could be used to release and

ial were compacted into a Proctor cylinder for

reclaim ammonia through a specially designed

physical testing. A portion of this compacted cyl-

emissions control capture system on the transport-

inder was allowed to cure and was set aside for

able treatment unit prior to DCR processing.

additional chemical analyses to assess the effects

The DCR process (unlike other pozzolan-based

of lower DCR reagent utilization and sample

6

Previous Page

Previous Page