20

15

KC1

10

5

0

Air

5

20

22

24

26

28

30

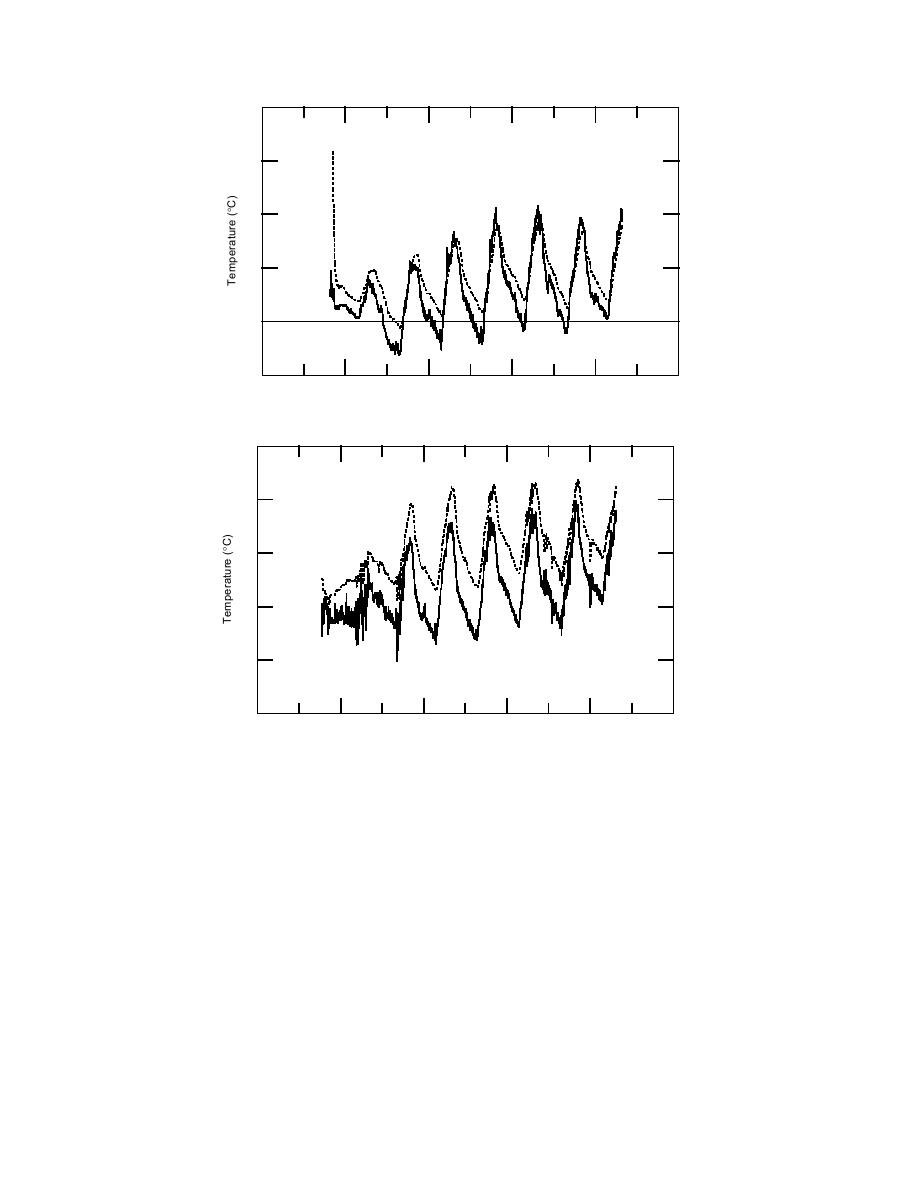

March 1995

a. An unheated shelter.

25

Control

20

15

10

Air

5

0

20

22

24

26

28

30

March 1995

b. A heated shelter.

Figure 21. Thermal history of the masonry walls and surrounding air.

15.3C (60F), a maximum of 22C (71.6F) at 5:15

mortar joints. Figure 21 shows the 7-day tempera-

p.m. on the 27th, and a minimum of 10.1C (50F)

ture history of the cylinders and air in each side of

at 5:15 p.m. on the 21st.

the shelter. The initial mortar mixture tempera-

tures were approximately 17C (62F) for both

Mortar strength

conventional and antifreeze mortars. While typi-

Two sets of 50- 100-mm (2- 4-in.) cylindrical

cal protection methods for newly constructed

samples were cast from each type of mortar. The

concrete masonry may include overnight heated

samples made from the conventional mortar

enclosures, the heated wall section for this project

were stored in the warm side of the shelter, and

was protected for a full 7 days. The mortar on the

those from the antifreeze mortar were stored in

unheated side of the shelter had a 7-day average

temperature of 3.9C (39F), a maximum temper-

the cold side. The cylinders were allowed to cure

ature of 9.5C (49F) at 3:30 p.m. on the 26th, and

in their respective environments for 7 days. Then

a minimum of 0.6C (31F) at 7:30 a.m. on the

they were shipped to CRREL, stored at room tem-

perature, and tested at a maturity of 28 days. The

23rd. In contrast, the mortar on the heated side of

strength results are presented in Figure 22. The

the shelter had a 7-day average temperature of

25

Previous Page

Previous Page