38

36

34

KC1

32

Control

30

28

26

0

10

20

30

40

50

Time (min)

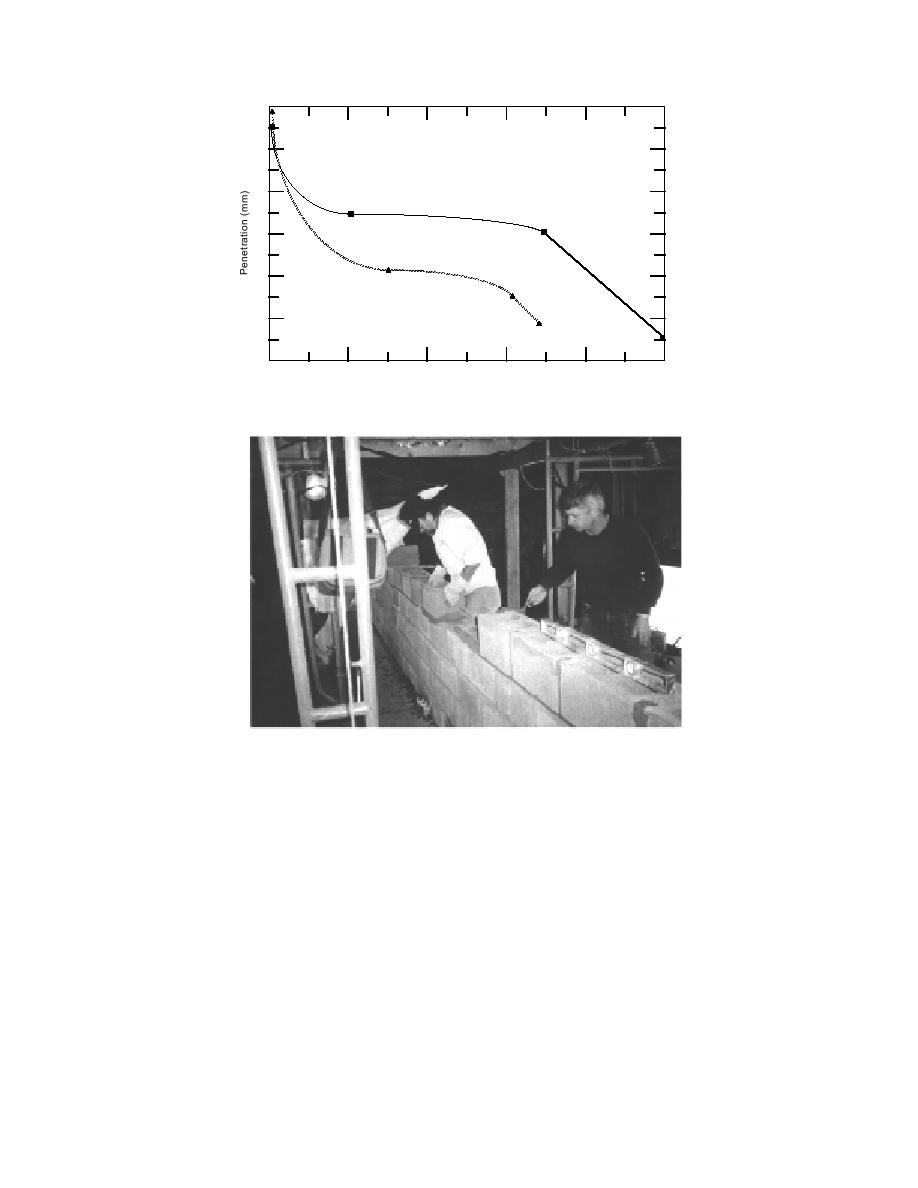

Figure 19. Penetration of mortar with and without the antifreeze admixture.

Figure 20. Building the wall.

masonry construction techniques. The mortar

antifreeze mortar batches were not retempered.

was tooled concave when it was thumbprint

For construction of the wall section (Fig. 20) on

hard. The masons found that the admixtured

the cold side, masonry units were transferred

mortar adhered very well to the masonry units

from the heated enclosure and used immediately.

and that it remained workable much longer than

The mortar made with KC1, once mixed, was

did the conventional mortar; this was probably

placed in the cold side and used within about 50

due to the differences in air temperature. Figure

min.

19 compares the average penetration of the three

conventional mortars (on the warm side) to the

Thermal history

average penetration of the three admixtured mor-

Mortar and air temperatures were recorded

tars (on the cold side) over time. Due to the lower-

every 5 minutes for seven days. Thermocouples

than-average initial mixing moisture content, the

in each side of the shelter monitored tempera-

cone penetrations for the fresh mortar averaged

tures in the mortar beds between masonry units,

in 5 10 cm (2 4 in.) mortar cylinders, and in the

about 38 mm (1.5 in.). The masons retempered the

mortar when its penetration dropped to about 28

air next to the walls. The temperature of the mor-

mm (1.1 in.). The three batches of conventional

tar cylinders, which were stored adjacent to the

mortar were each retempered once, but the two

wall sections, was nearly identical to that in the

24

Previous Page

Previous Page