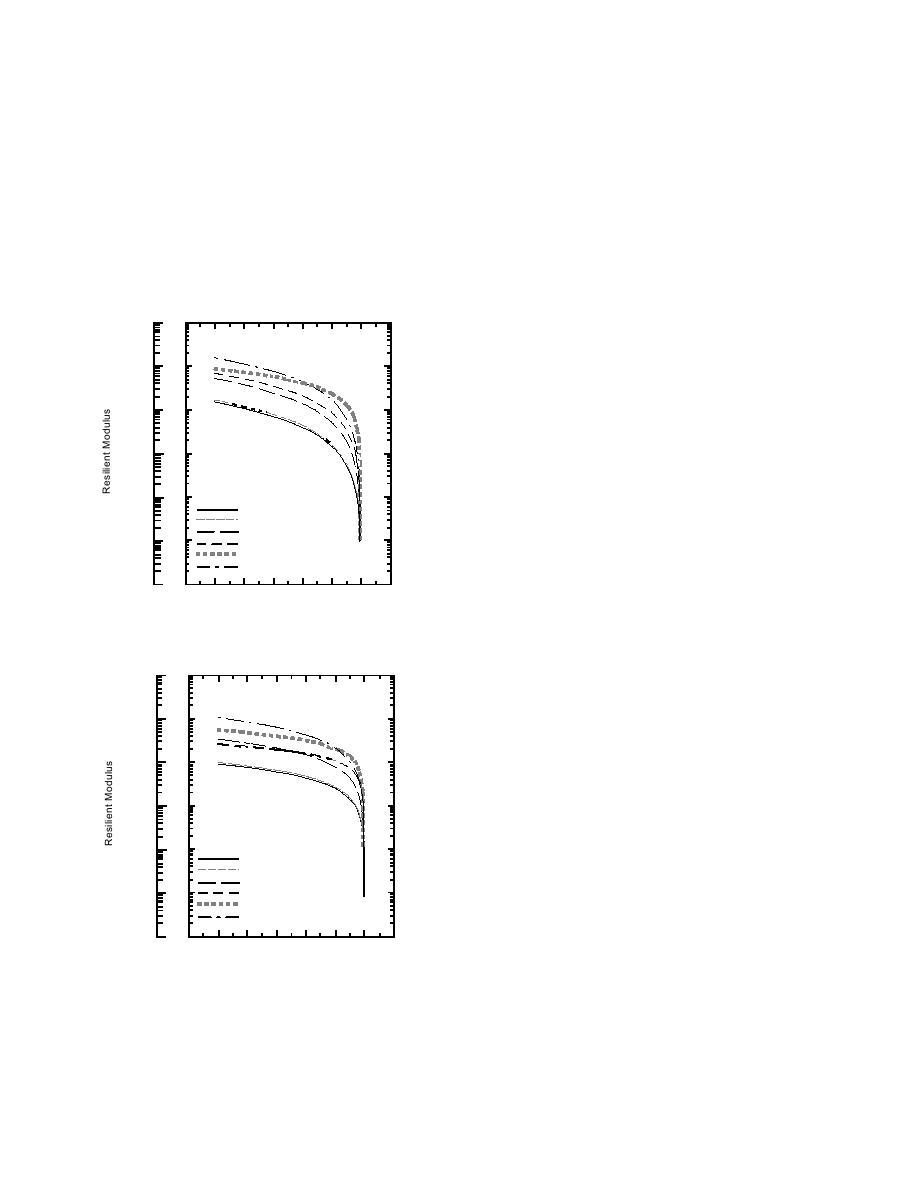

ing. Also shown is a line representing the pre-

binations applied (Table 3a). In the case of the

dicted moduli resulting from the equations given

1206 subgrade and the class 6 special base, it also

in Table 6, at the mean stress level tested. Where

relates to the variation in density. To show the

dry density is included in the equation, it was set

influence of density in the 1206 subgrade data,

at the average value of all specimens tested. It can

Figure 8 differentiates the data from three density

be seen in Figures 7a through 7f that moisture

ranges (high, medium, and low), along with the

level does influence the unfrozen moduli, but to

corresponding predicted resilient moduli lines.

different degrees, depending on the material.

Note that the low density moduli are most repre-

The vertical spread in the data points at a par-

sentative of moduli back-calculated from FWD

ticular degree of saturation (Fig. 7) is the result of

deflections measured on site at Mn/ROAD.

the materials response to the different stress com-

The effect of stress combinations is shown in

Figure 9 for the low-density 1206 subgrade data,

(lb/in.2 )

(kPa)

and all of the 1232 subgrade and class 3 special

8

7 x 10 8

10

subbase data. The two subgrades display an in-

verse relationship between modulus and deviator

stress; the class 3 special subbase has a propor-

tional relationship between modulus and the stress

6

7 x 10 6

parameter J2/τoct.

10

Figure 10 demonstrates the relative influence

of the deviator stress and confining pressure (σ3)

on the modulus of a single 1206 subgrade speci-

4

men at 16.1% water content. The deviator stress

7 x 10 4

10

1206

has the major influence, while confining pressure

1232

Class 3

produces only minor variations in the moduli. The

Class 4

figure also includes a line of predicted resilient

Class 5

Class 6

moduli based on a regression analysis of these

2

7 x 10 2

10

data alone, in the form:

-12

-10

-8

-6

-4

-2

0

2

Temperature (C)

Mr (lb/ft2) = K1 (σd)K2,

a. Governing parameter wug/wt.

as well as the upper and lower 95% confidence

(lb/in.2 )

(kPa)

interval around the mean line. The confidence band

108

7 x 10 8

brackets the variation in modulus related to σ3.

We generated several predicted curves for indi-

vidual samples as described above to isolate the

influence of moisture content and density, respec-

106

7 x 10 6

tively, on the resilient modulus of the 1206 sub-

grade material. Figure 11 shows the relationship

between modulus and deviator stress of specimens

with a similar density, but with different moisture

4

levels. It confirms the expected relationship that

7 x 10 4

10

1206

the drier sample exhibits a higher modulus at simi-

1232

Class 3

lar stress conditions. Figure 12 compares two

Class 4

samples with similar moisture, showing that the

Class 5

Class 6

higher density sample has higher moduli.

102

7 x 10 2

A comparison of the predicted modulus curves

-12

-10

-8

-6

-4

-2

0

2

Temperature (C)

generated by the equations in Table 6 for all the

b. Governing parameter wuv.

materials studied is given in Figure 13. Among

the curves of the base/subbase materials, there is a

Figure 6. Predicted frozen resilient modulus

general increase in the predicted moduli as the

for all Mn/ROAD materials.

14

Previous Page

Previous Page