(lb/in.2 )

(lb/in.2 )

(kPa)

(kPa)

6

106

7 x 10 6

7 x 10 6

10

1206 Unfrozen

3

115 lb/ft

7 x 10 5

5

105

5

108

7 x 10

10

105

Calculated σd (lb/in.2 )

4

7 x 10 4

104

7 x 10 4

10

Density (lb/ft 3)

0.5

1.0

High

114 - 117

4.0

107 - 110

Medium

10

104 - 106

Low

14

3

3

7 x 10 3

3

7 x 10

10

10

100

80

60

40

100

80

60

40

Degree of Saturation (%)

Degree of Saturation (%)

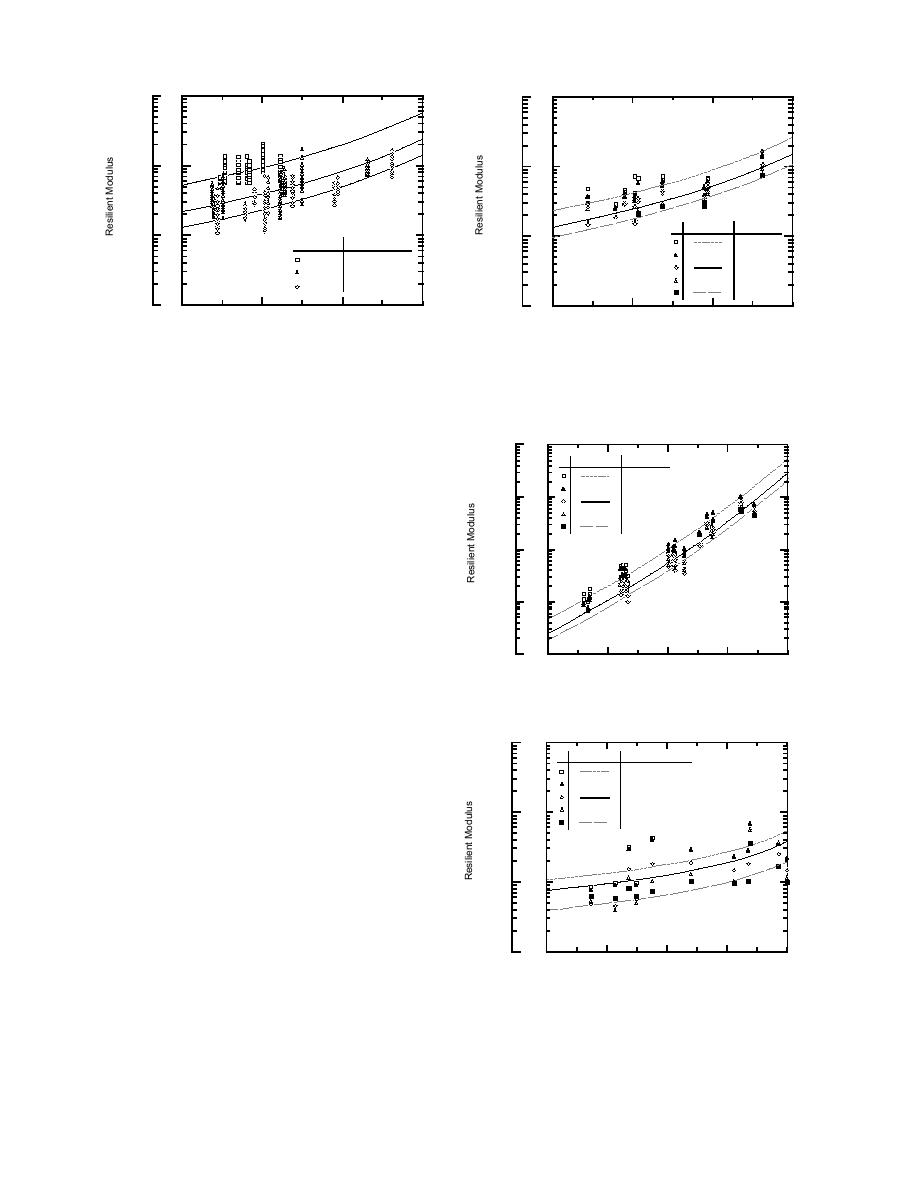

a. Low-density (1.661.7-Mg/m3 or 104106-lb/

Figure 8. Resilient modulus vs. degree of satura-

ft3) 1206 subgrade. (These data are probably in

tion of never-frozen 1206 subgrade material il-

lustrating the effect of dry density.

error--see text.)

(lb/in.2 )

(kPa)

amount of fines in the material decreases, with the

6

6

10

7 x 10

exception of the class 4 special material. There is

Calculated σd (lb/in.2 )

also a decrease in the slope of the predicted curves

0.5

1.0

with decreasing fine content, indicating the ex-

5

5

7 x 10

10

5.0

pected lesser influence of moisture content on the

9.0

14

moduli of the coarser materials. The curves of the

4

7 x 10 4

two clay subgrades depart somewhat from this

10

pattern. The curve for the 1232 subgrade has an

extremely steep slope, showing a much stronger

10 3

3

7 x 10

influence of the degree of saturation on the modu-

lus. The curve of predicted moduli for the 1206

1232 Unfrozen

subgrade is higher than those for the coarser

2

2

10

7 x 10

100

90

80

70

60

materials. Although this is contrary to conven-

Degree of Saturation (%)

tional rules-of-thumb, high moduli for cohesive

b. 1232 subgrade.

materials have also been reported by Robnet and

Thompson (1973). However, it is more likely that

(lb/in.2 )

(kPa)

6

7 x 106

10

the high 1206 subgrade moduli are related to the

Calculated J 2 / τoct (lb/in.2 )

miscalibration of the testing machine. This possi-

640

bility is being investigated in more detail and find-

330

117

ings will be included in the Phase 2 report (Berg

5

5

58

7 x 10

10

in prep.).

5

For each material tested, Figure 14 shows the

frozen and thawed/unfrozen moduli data points

7 x 104

104

and curves based on the regression equations re-

sulting from this analysis. Data in Figure 14 illus-

trate the rapid increase in modulus as the soils

Class 3 Subbase

freeze and a lower-magnitude increase in modu-

7 x 103

103

lus values with decreasing saturation. To illustrate

100

80

60

40

20

Degree of Saturation (%)

these general trends, the calculated relationships

c. Class 3 special subbase.

vs. degree of saturation are also shown, for one

Figure 9. Resilient modulus vs. degree of satura-

stress condition only. As shown in Figure 9, stress

tion illustrating effect of stress parameters.

conditions also influence resilient modulus values.

16

Previous Page

Previous Page