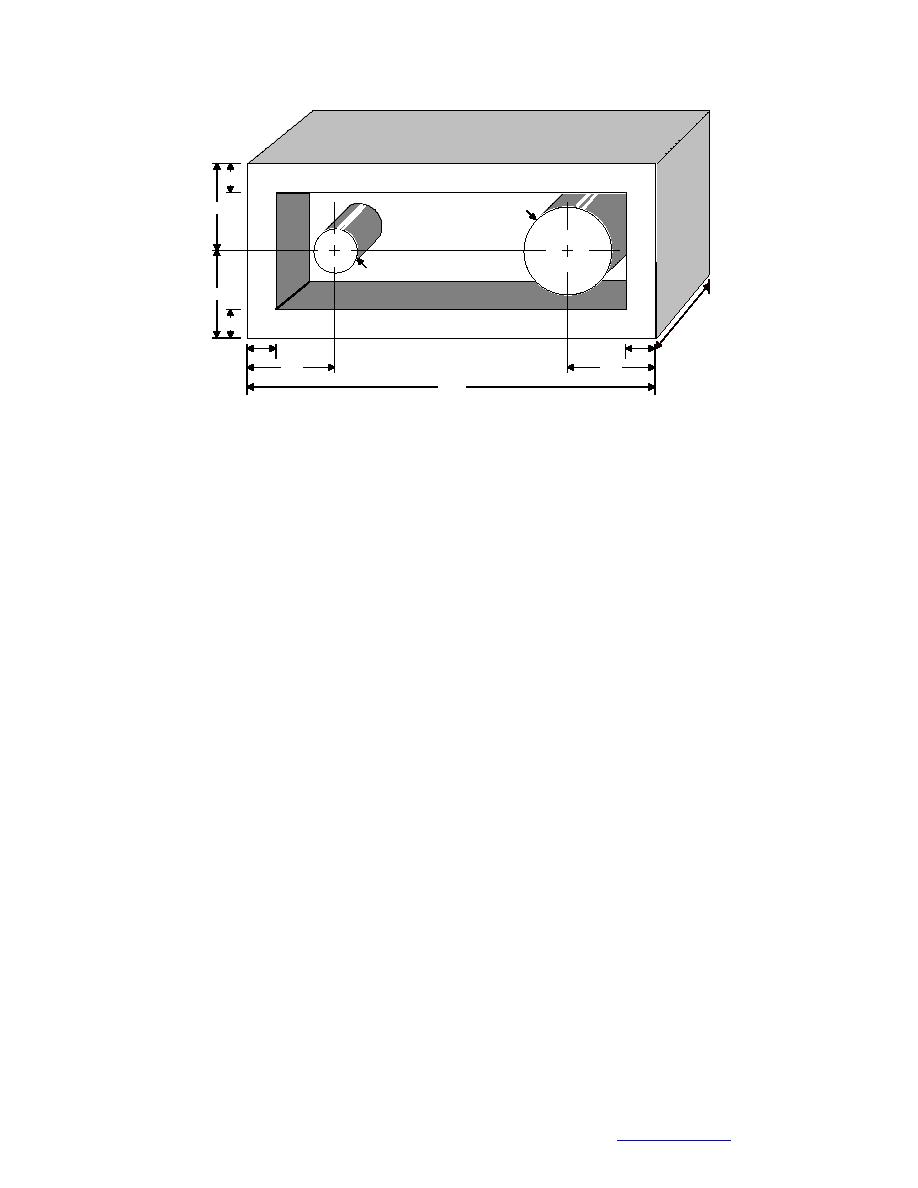

2 in.

6 in.

6-in. diameter

3-in. diameter

6 in.

2 in.

5.15 in.

2 in.

2 in.

6 in.

6 in.

28 in.

Figure 5. Experimental configuration of Stewart and Verhulst (1985)

Stewart and Verhulst (1985) presented the results of experiments in which two

heated cylinders were in a cooled rectangular enclosure. Figure 5 shows their

apparatus, which was filled with distilled water; measurements were made with

both cylinders heated and when heated individually. They investigated a number

of different characteristic lengths and found that the best correlation (least devia-

tion from the data) occurred when the hypothetical gap width L was used. (When

more than one pipe was used to calculate L, an effective radius that included both

interior pipes was used.)

For both cylinders heated

NuL = 0.420RaL.219

0

(L includes both cylinders)

(43)

NuL = 1.534Ra L.169

0

(L using large cylinder only)

(44)

NuL = 0.231Ra L.243

0

(L using small cylinder only).

(45)

For only one cylinder heated

NuL = 0.256Ra L.266

0

(large cylinder heated, L using large

(46)

cylinder only)

NuL = 0.027 Ra L.371

0

(small cylinder heated, L using small

(47)

cylinder only).

Babus'Haq et al. (1986) used interferometric flow visualization to determine the

optimized location of a single warm pipe in a cool square enclosure with the antici-

pated application being district heating distribution lines, i.e., utilidors. Figure 6

is a diagram of their experimental apparatus. Although Babus'Haq et al. did not

develop any heat transfer correlations per se, their data for heat loss from a cen-

tered pipe to the enclosure walls can be represented by

NuG = 0.34GrD.25

0

(48)

9

Back to Contents

Previous Page

Previous Page