and lowered the mat into place. It took

about one hour to place these mats.

Since the all-terrain forklift could not

be used to deliver the last four mats, a

new method using the HEMTT was

tried. The mats were arranged in two

rows of two mats each. The mats in the

rows were overlapped by one foot and

attached together. The HEMTT then

pulled the mats up the slope close to

their final location. Then the HEMTT

winched each set of two mats into their

final position.

On the wooded trail, the tire mats

were delivered to the north end of the

wooded trail in 5-ton dump trucks. The

HEMTT was then used to place the

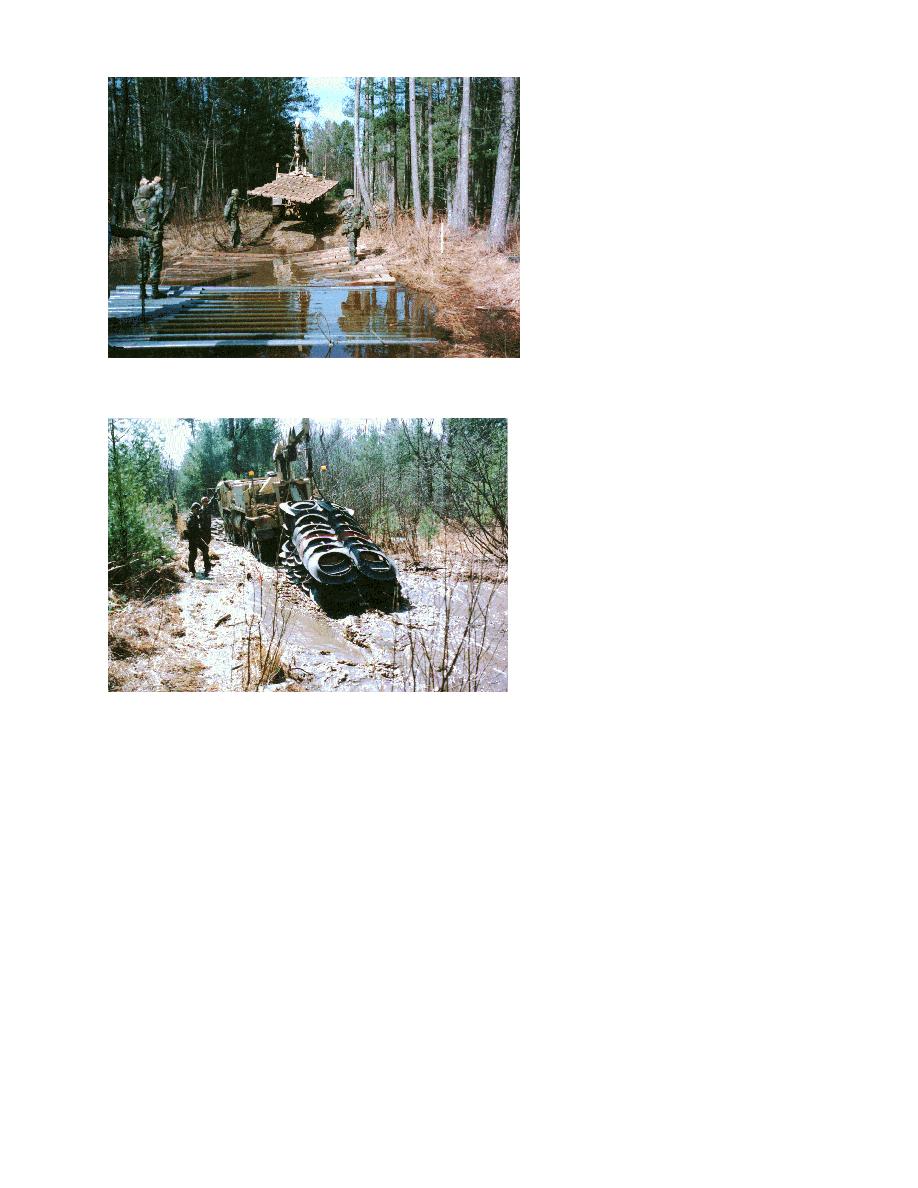

Figure 4. Placing Uni-Mats in wet site.

mats. First, the mats were laid end-to-

end with 0.3 m (1 ft) of the second mat

lying on top of the first, etc., until eight

mats were laid out. The mats were then

fastened together. Plans were to drag

the mats in a manner similar to that

used on the sloped trail. This method

failed because the chain on one of the

mats broke. The mats were then ar-

ranged in a stack of four and carried/

dragged by the HEMTT (Fig. 5) to the

test section where they were placed

close to their desired position. Each

mat was then picked up individually

and placed in position.

On the pentagonal loop trail, the tire

mats were delivered on a lowboy, off-

loaded, and placed with a bucket

Figure 5. Placing tire mats onto wooded trail section.

loader with teeth. The test section

shape was then modified to "round"

the corners. A D7 bulldozer was used to move the

ing area to the test section--a distance of approxi-

mats into their new position.

mately 120 m (400 ft).

Tire mats

PVC fascine mats

Tire mats were provided by Terra Mat. The

A fascine is a series of parallel pipes placed

mats were 1.6 m (5.25 ft) wide by 3.2 m (10.5 ft)

to fill a ditch that allows traffic to travel across

long and weighed approximately 1000 kg (2200

(Fig. 6a). In contrast to a typical military fascine,

lb) each. There was a lifting chain at each end.

the fascine mats used for this demonstration

The mats were placed along the wheel tracks.

project were constructed of materials similar to

On the sloped trail, the first six tire mats were

those used by the USFS (Mason 1990), e.g., 6-m-

moved to the test section using an all terrain fork-

(20-ft-) long schedule 80 PVC pipe, 1.6 cm (5/8

lift. The mats could not be placed using the fork-

in.) steel cable and cable clamps. Two 4.6-m-

lift because its brakes were not adequate on the

(15-ft-) long by 4.9-m- (16-ft-) wide fascines were

steep grade. The bucket loader was used to place

constructed.

these mats. One end of the tire mat was attached

The fascine was used in two locations on the

to the bucket and lifted from the stack. The loader

wooded trail. The first location was at a bend in

then placed the lower end of the mat on the ground

the trail where the tank had thrown a track just

12

Previous Page

Previous Page