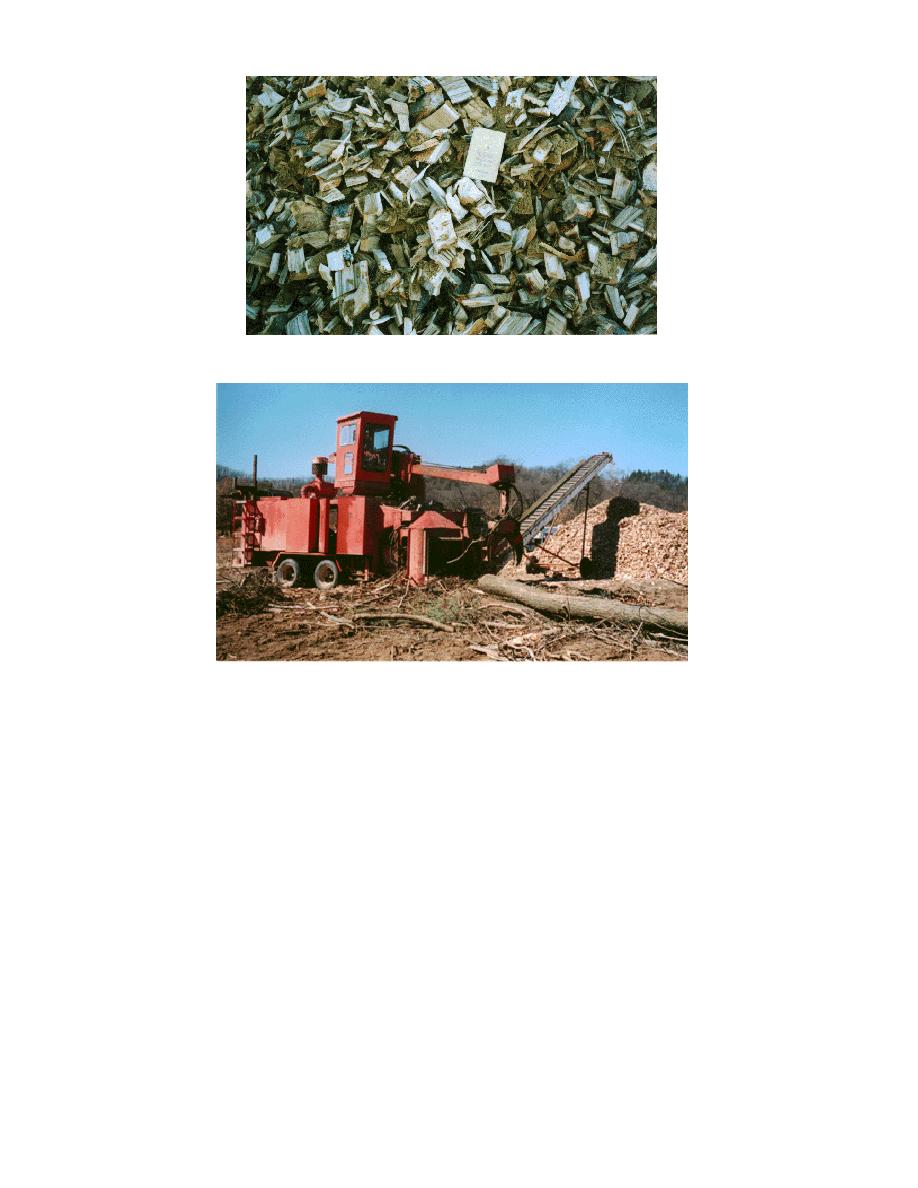

a. Chunkwood fill.

b. USDA Forest Service wood chunker.

Figure 8. Chunkwood.

Tire chips

easily by construction trafficking and provided a

The tire chips were produced by shredding car

good wear surface.

and truck tires until they passed a 5-cm (2-in.)

screen. There was a significant amount of bead

Slash

steel mixed with the tire chips. The tire chips had

The slash was produced by first felling trees,

a density of approximately 643 kg/m3 (40 lb/

loading them in trucks, and delivering them to

ft3). The bulking factor appeared to be low. The

the test sections. Trees with diameters less than

tire chips did not appear to compact significantly;

20 cm (8 in.) were used on the slope. The maxi-

the surface remained springy even after several

mum diameter used for other test sections was

passes of a D7 bulldozer.

approximately 8 cm (3 in.). A variety of species

were used.

Gravel

Slash was transported to the sloped trail test

The gravel was obtained from a stockpile at

section in 5-ton dump trucks as whole trees. The

Fort McCoy. It is used for their conventional gravel

trees were then cut up by chainsaws so they could

roads. The gravel had a density of approximately

be moved by hand and placed on the trail gener-

1922 kg/m3 (120 lb/ft3). The gravel compacted

ally perpendicular to the direction of travel. The

14

Previous Page

Previous Page