with the M60 and not the HEMTT, because tracks

granular fill placed on lower bearing capacity sub-

are significantly more destructive on corners. The

grades to help bear traffic loads. For subgrade

drivers attempted a constant vehicle speed over

CBRs of 1 to 3, a geotextile is needed to keep fill

all the sections 16 to 32 km/h (10 to 20 mph) and

and subgrade soil separate. At CBR values less

any significant speed variation caused by the sur-

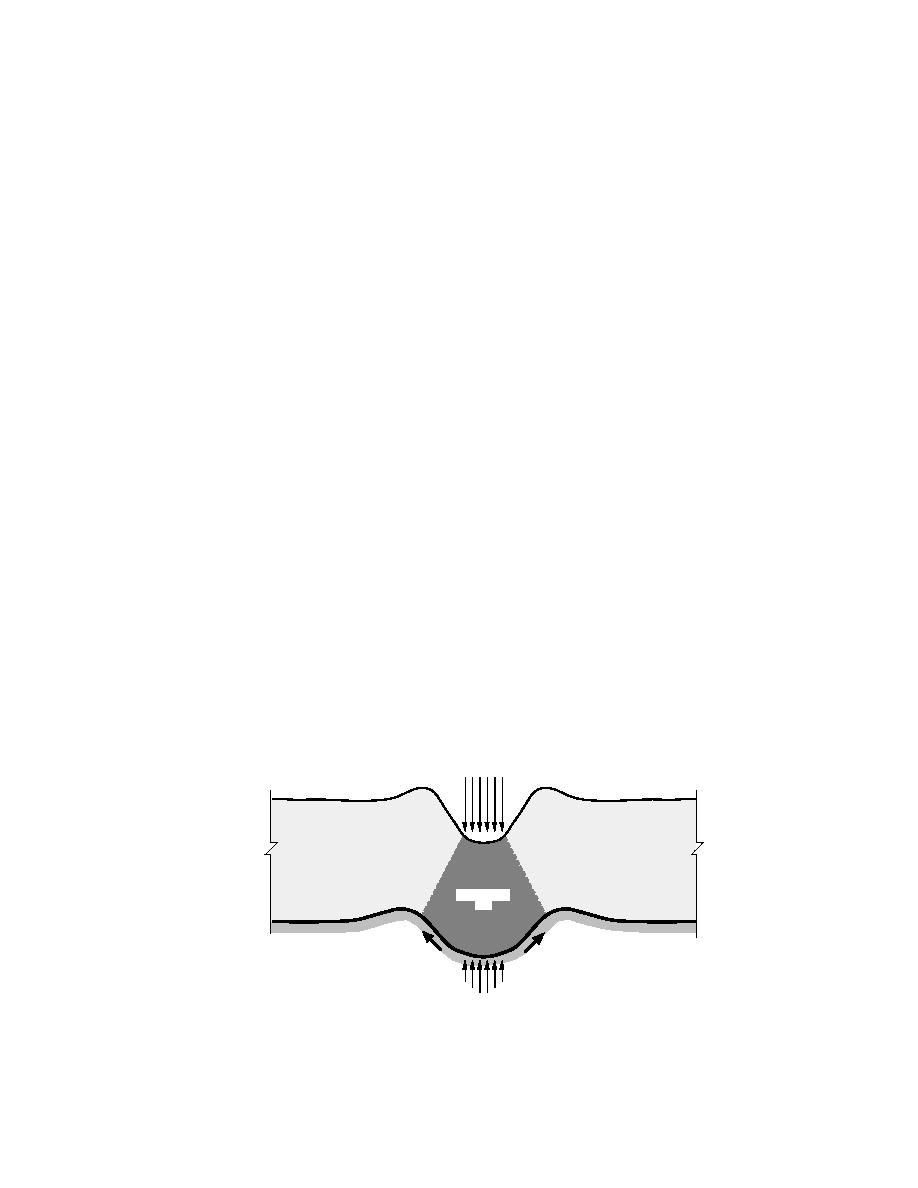

than 1.0, geotextiles or geogrids often provide

faces was recorded.

reinforcement as well as separation. When used

The performance of vehicles and test sections

with little or perhaps even no fill, high strength/

was evaluated after 1, 10, 25, and 50 passes of

high modulus geosynthetics can help bear loads

each vehicle. Each test section was evaluated for

through "membrane support" of the wheel loads

rutting, lateral expansion of the trail, failure of the

(Fig. 10) (Giroud and Noiray 1981). Membrane

surface material, interference of the material with

support refers to the deformation and tensioning

the vehicle, movement of the surface material,

of the geosynthetic to help bear the traffic load

vehicle slipping, repairs, etc. The vehicle drivers

(i.e., ruts must form in the geosynthetic). Even

evaluated the performance of the test sections

though the stabilization techniques tested were

with respect to vehicle operation, loss in traction,

not specifically chosen for their ability to improve

braking, vehicle handling and steering, necessary

traction, qualitative observations of traction were

adjustments to vehicle speed, material interfer-

documented.

ence with vehicle components, etc. The drivers

The remainder of this section describes the traf-

also gave each test surface an overall ranking, as

ficking tests that were conducted and observa-

indicated on the sample evaluation forms, also

tions made during and after the tests.

provided in Appendix G. Final observations and

photo documentation of each test section were

Sloped trail

completed after each vehicle completed the 50

Trafficking of the sloped test site occurred over

passes. The vehicle drivers and test section evalu-

three days. It began on 20 March 1995, with the

ators were then interviewed on video to docu-

HEMTT making 30 passes. The weather was

ment users' thoughts and ideas, expanding on the

snowy, rainy, and windy. On 21 March 1995, the

written surveys.

weather cleared and the HEMTT made an addi-

As mentioned earlier, all of the stabilization

tional 20 passes followed by 25 passes with the

techniques tested in this program improve soil

M60 tank. Tank trafficking finished with 25 passes

bearing capacity by distributing traffic loads over

on 22 March 1995. The weather was sunny and

a larger area. "Rigid" materials with flexural stiff-

clear and the soil appeared to be drier on the third

ness (i.e., wooden mats, slash and possibly to a

day of trafficking.

small degree, the geonet) distribute loads to the

After the HEMTT and before tank trafficking

thawing soil largely through beam action. Chunk-

began, one 20-cm- (8-in.-) diam. tree trunk was

wood and tire chips are alternatives to the use of

removed from the slash test section at the request

Wheel

Load

Cohesionless

Base Material

Wheel Path

Rut

Geotextile

Soft Cohesive

Tension

Subgrade

in Fabric

Vertical Support Component

of Membrane-type Action

Figure 10. Membrane support (Giroud and Noiray 1981).

16

Previous Page

Previous Page