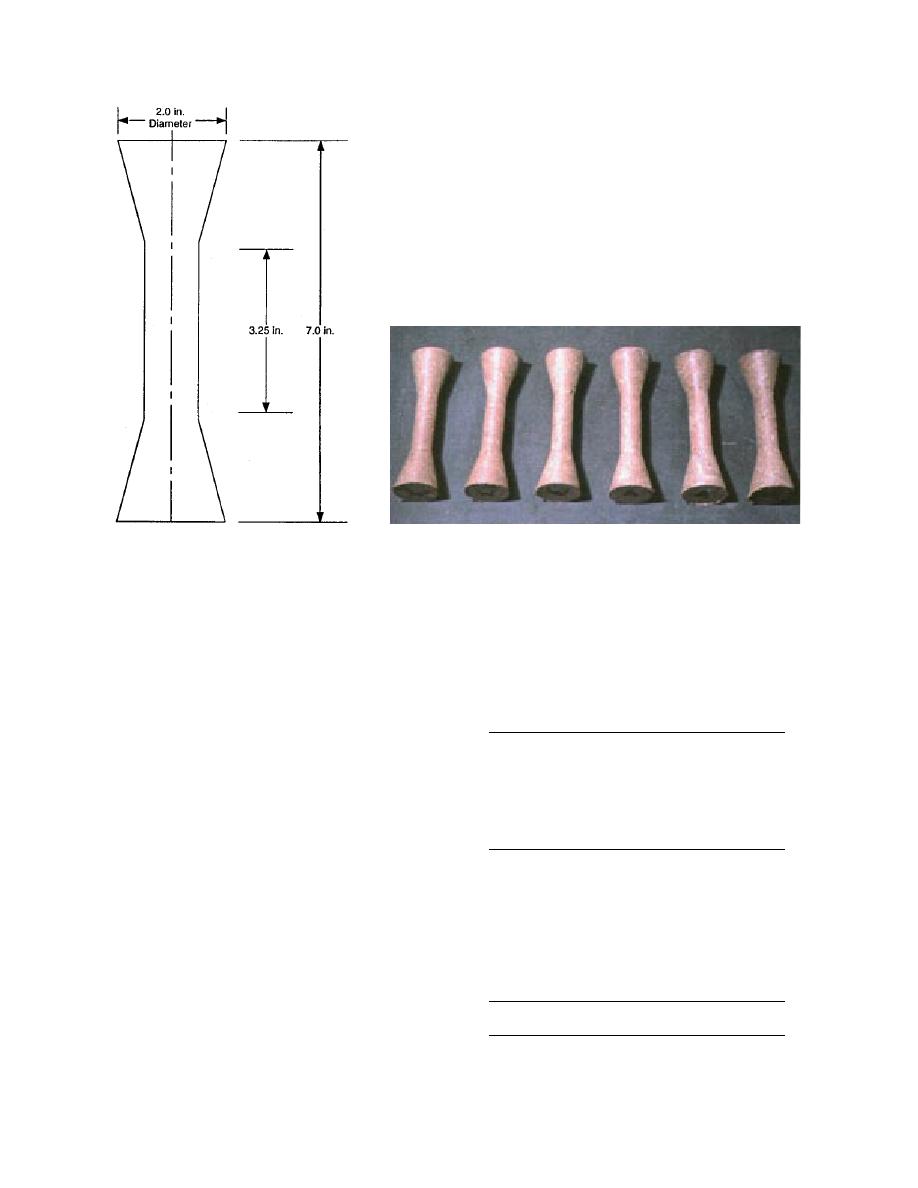

b. Some RPC tensile test specimens machined from the 152- 203-

a. Tensile test specimen dimensions for

mm (6- 8-in.) beams.

the RPC material.

Figure 48. Tensile test specimens for the RPC material.

ture for testing these specimens was also designed,

Table 8. Tensile test data of RPC.

as shown in Figure 49. Figure 49a shows the fix-

ture cover plate removed, and Figure 49b shows

Specimen

Peak load

Area

Strength

(in.2)

(lbf)

(psi)

(psi)

Modulus

the cover plate closed. Again, the tension tests

were conducted in the servohydraulic machine

x direction specimens

with a cross-head displacement rate of 2.54 mm

W1

372.0

0.7933

468.93

23,628

(0.1 in.) per min. An electrical data acquisition sys-

W2

290.5

0.7838

370.63

19,383

W3

N/A

0.8028

N/A

14,290

tem was used to record the test data. From the

152 203-mm (6 8-in.) beams supplied by the

W4

332.5

0.7948

418.34

28,432

W5

400.0

0.7933

504.22

31,570

manufacturer, six specimens, W1 through W6,

W6

240.0

0.7933

302.53

19,637

were machined from the longitudinal direction (x),

Average

412.92

22,823.33

and six specimens, A1 through A6, were machined

Std. dev.

79.81

6,378.33

from the major transverse (y) direction. Figures

y direction specimens

50a and b show the typical stress-strain curves for

A1

512

0.8075

634.06

27,820

the tensile loading in the x and y directions. The

A2

487.5

0.7917

615.76

23,046

properties were determined only in the longitu-

A3

332

0.7964

416.88

29,116

dinal (x) and the major transverse (y) directions

A4

321.5

0.7948

404.50

25,502

at room temperature The results of the tension

A5

334

0.7933

421.03

26,307

A6

413.5

0.8028

515.07

35,130

tests are summarized in Table 8.

Average

501.22

27,820.17

These results are graphically presented in Fig-

Std. dev.

103.78

4,136.88

ure 51. Figure 51a gives the tensile strength data,

and Figure 51b give the elastic modulus for the x

SI conversion factors: 1 lbf = 4.45 N, 1 in.2 = 645 mm2 ,

direction specimens. Figures 51c and d give the

1 psi = 6.89 kPa.

34

Previous Page

Previous Page