(21C, 70F) and at low temperature (30C, 22F)

under wet and dry conditions. Results of the Dou-

glas fir flexural tests are summarized in Table 10.

The moisture percentages of the wet specimens

of both the RPC and the Douglas fir were deter-

mined immediately before the flexure tests by the

weight gain (difference between wet density and

dry density) of each specimen after water immer-

sion. The moisture gain varied with time. A sum-

mary of the results is presented in Table 11. The

data in Table 11 show that for a given size of speci-

men, moisture ingression was greater in the Dou-

glas fir than in the RPC.

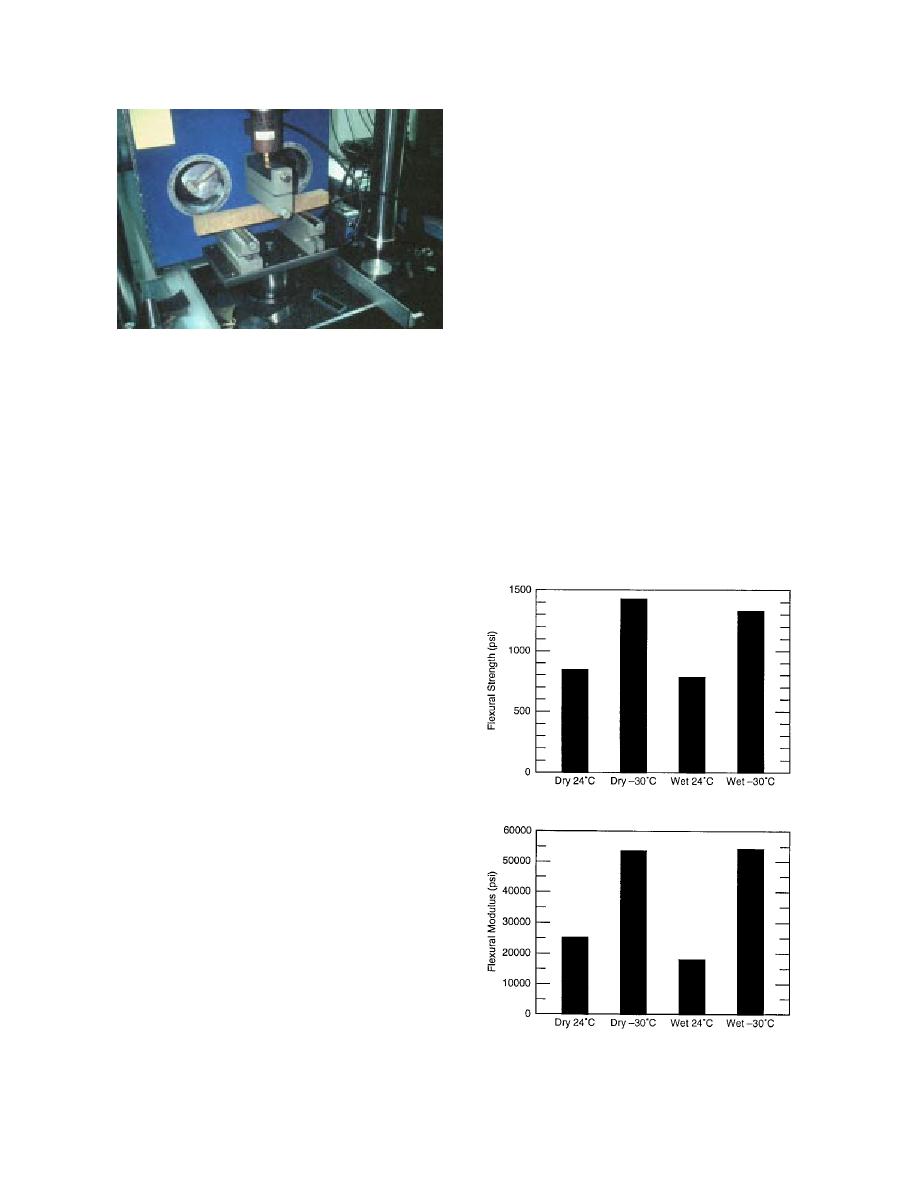

Figure 52. Flexural testing of the RPC.

The influence of temperature and moisture in-

gression on the flexural behavior of the RPC is

represented in Figure 53. Figure 53a shows the

flexural strength (S) and Figure 53b the flexural

modulus (Ef). They show that low temperature

same for the y direction specimens, respectively.

influenced the flexural behavior of the RPC sig-

The material clearly shows a significant amount

nificantly--in fact, much more significantly than

of variability in properties between the speci-

moisture. The average values from all tests are

mens. However, the y direction specimens are

summarized in Table 12. The flexural strength

stronger and stiffer overall than the x direction

for the dry RPC specimens (specimens DCD)

specimens. It is possible that transverse pressure

increased approximately 63% at 30C (22F),

and compacting of the materials at the time of

and the flexural modulus by approximately

forming in the die impart a higher strength to the

material.

Flexural testing

As in compression, flexural testing of the

RPC was performed at room temperature and

low (30C) temperature for both dry and wet

conditions, using the servohydraulic machine and

a three-point bending fixture (Fig. 52). The data

were recorded by the electrical data acquisition

system. The flexural strength (S) and the flexural

modulus (Ef) were calculated using the follow-

ing equations for three-point bending of thin elas-

tic solids:

a. Flexural strength.

S = (3PL)/(2bd2)

where P

=

load on the beam

b

=

width of the beam

d

=

depth of the beam

L

=

span between the support points

δ

=

deflection of the beam.

All specimens were cut to the nominal size of

38.1 38.1 406.4 mm (1.5 1.5 16 in.). The

span (L) for all tests was 203.2 mm (8 in.). Results

from these tests are given in Table 9.

For the purpose of comparison, wood speci-

mens of Douglas fir of the same dimensions (38.1

b. Flexural modulus.

38.1 406.4 mm, 1.5 1.5 16 in.) were prepared

Figure 53. Results of flexural testing of the RPC.

and tested in flexure, both at room temperature

36

Previous Page

Previous Page